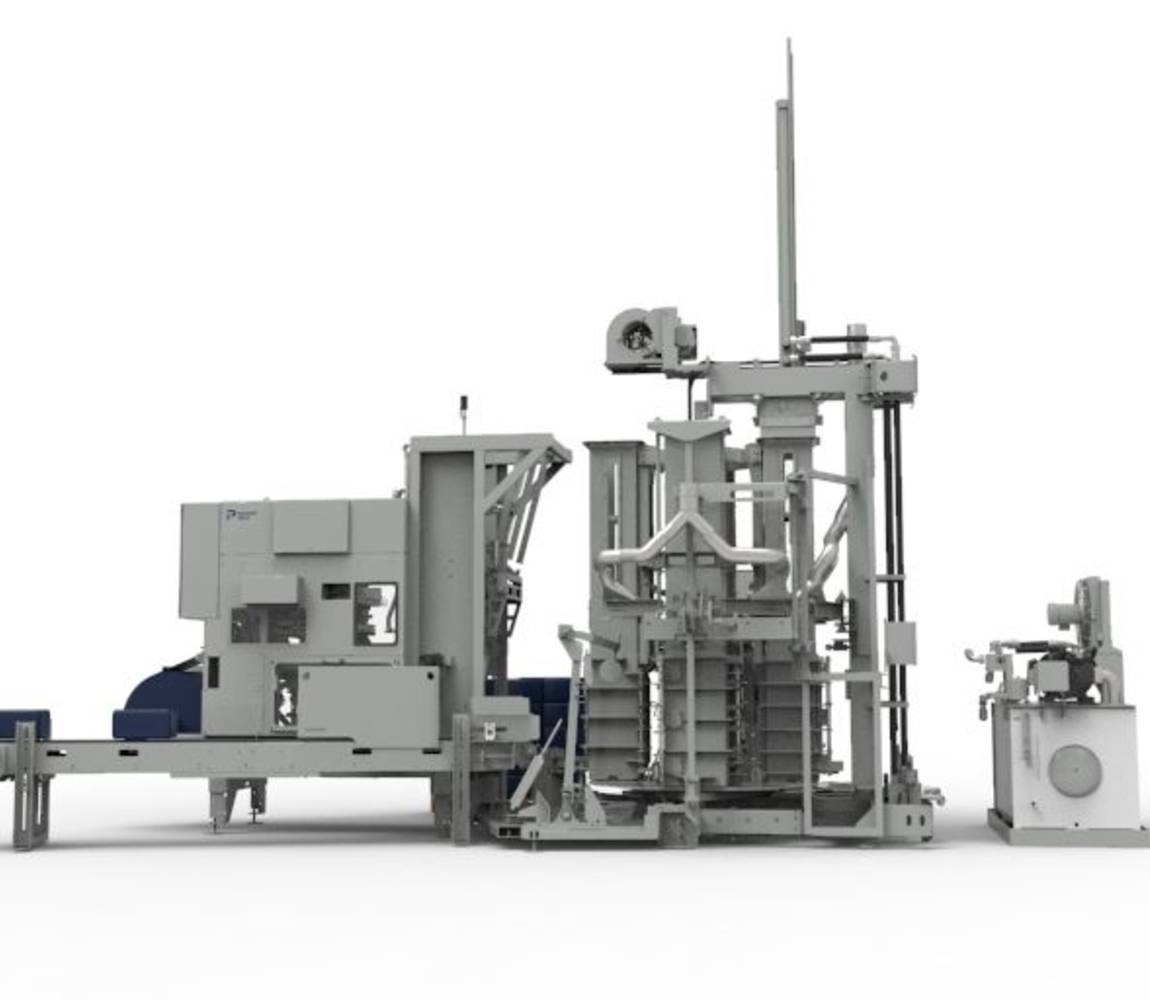

CHRONOS VP-415High-speed compression baler

Available in

Africa, Asia, Canada & USA, Europe, Latin America and OceaniaImproved by our international team over many years, the VP-415 is Premier Tech’s newest high-speed compression baler. Perfectly suited for peat moss, wood shavings, alfalfa, hemp and any other synthetic or natural compressible material, this compression baler is versatile and user-friendly.

This version of vertical compression baler allows an increase of 25% in production rate compared to previous versions for an outstanding ROI.

Speed: up to 6.5 bales per minute

Bulk materials: fibrous, flake

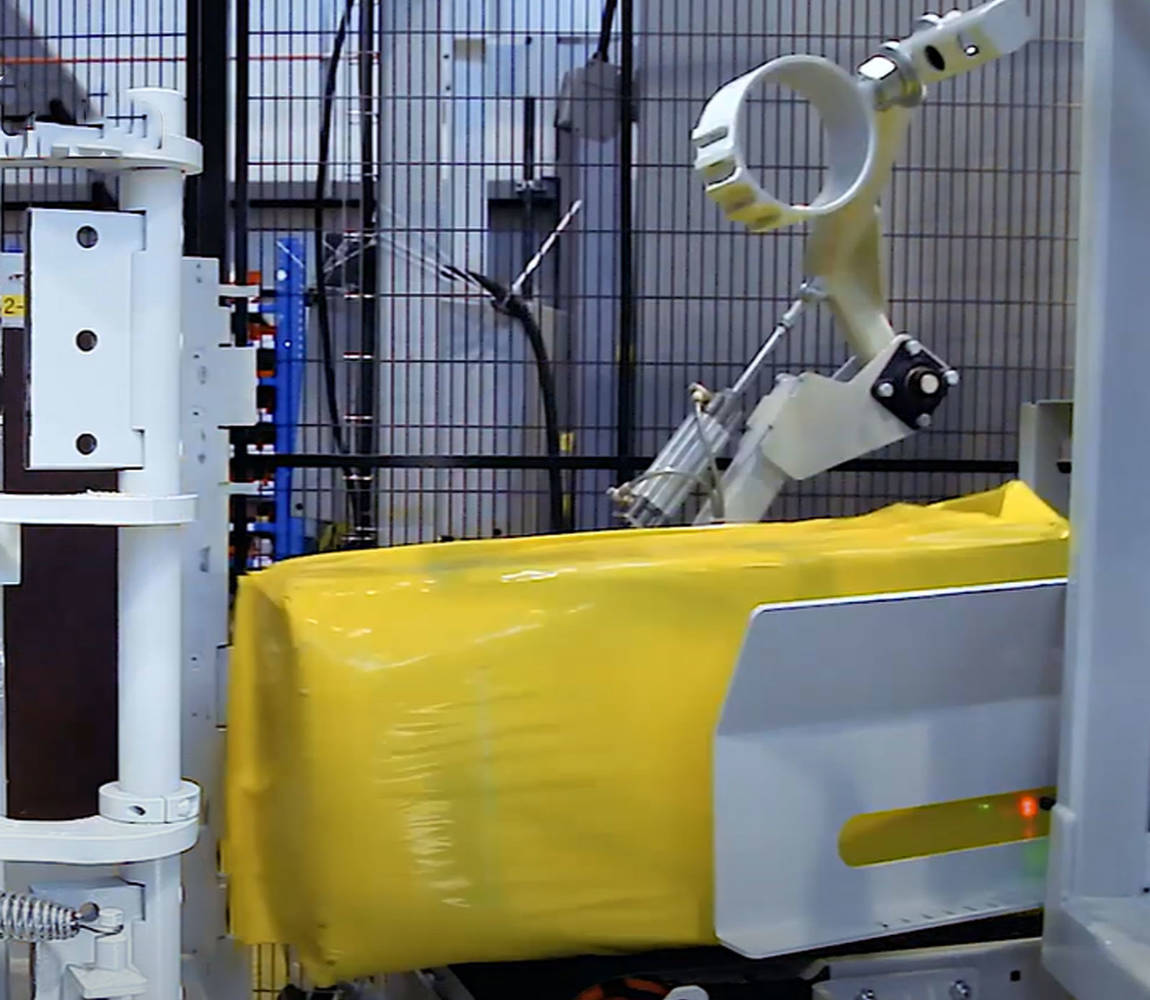

Bag types: gusseted flat bottom bale, tubular film

Bag materials: polyethylene with anti-static treatment

Bag weight: from 5 to 50 kg (11 to 110 lb)

Features

Performant

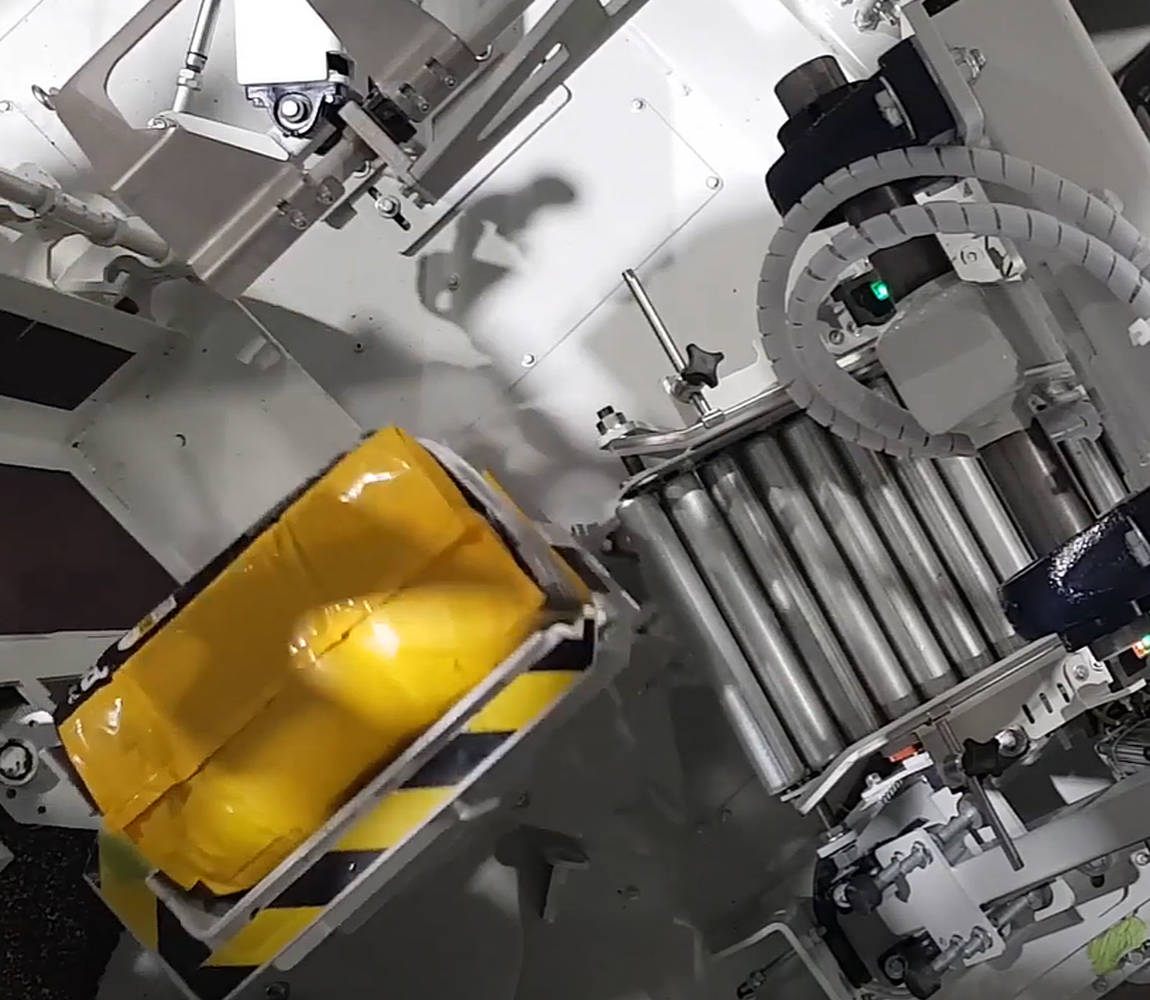

- Its compression force reaches up to 17.5 Imperial tons (155kN) and can offer a compression ratio up to 5:1

- Servo drive controlled table rotation for improved reliability and smoother operation

- High-performance sealer temperature controller

Versatile

- Can bag any type of compressible material

- Dual drawer bag magazine with automatic toggling

- Quick bag loading and bag changeover

- Single and multiple compression modes

Safe and easy to use

- User-friendly touch screen operator interface

- Rugged construction including widely used standard components requiring minimal maintenance

- Meets North American and European (CE) safety standards

Specifications

Typical footprint: 319” L x 254” W x 204 to 242” H (8100 x 6450 mm x 5180 to 6147mm)

Bag film thickness: 3.5 to 8 mils (90 μm to 200 μm)

Empty bale dimensions: 12 to 39" L x 14 to 18.5" W (305 to 990 x 355 to 470 mm)

Compression ratio: 5 : 1 *

Electrical requirements: 460 V/ 3 ph/ 60 Hz (400 V/3 ph/50 Hz)

* Depending on the application requirements and product characteristics.

Get pricing and additional information

Need help finding the right compression bagger?

Call us

We will be happy to answer

your questions

Sales

Parts & technical support

Request a quote

Tell us about your project, and we will reply with solution recommendations