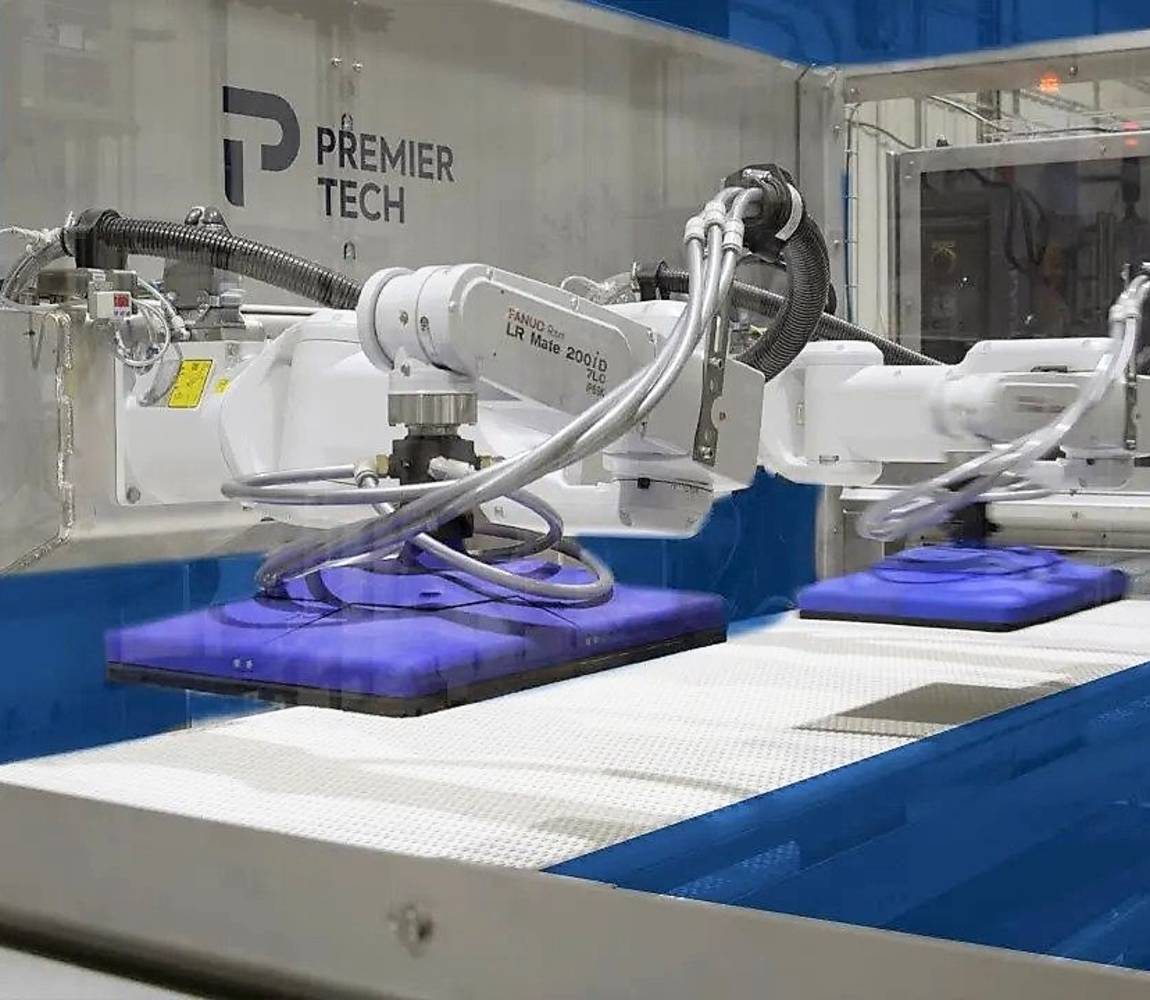

CHRONOS CPC SERIESRobotic case packer

Available in

Canada & USAThe CPC Series Robotic case packer (previously RPK Series) is designed to improve secondary packaging operations by packing multiple products into cases, trays, and totes.

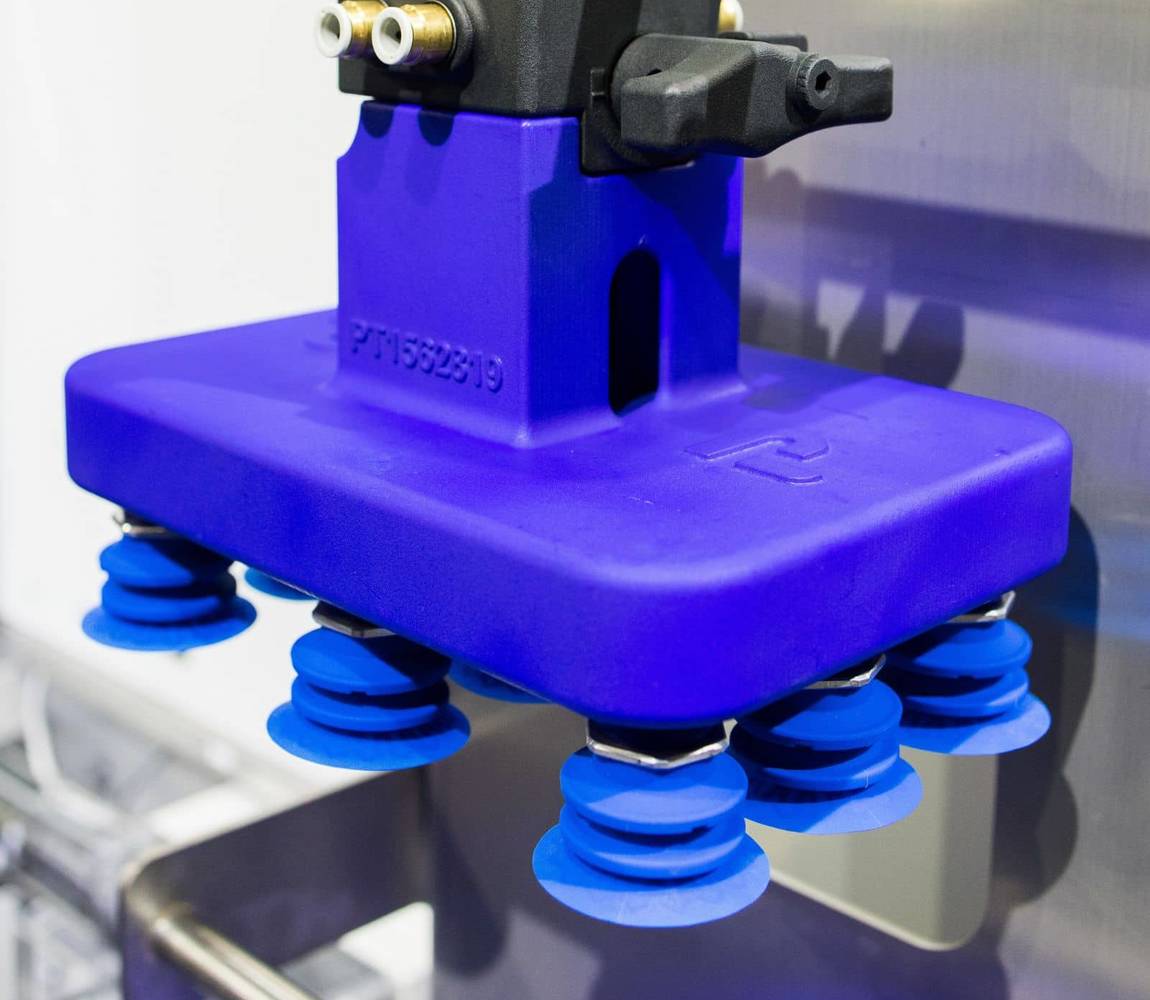

Its scalable design ranges from single to multiple packing robots, accommodating desired production rates and packaging patterns. The quickly interchangeable, 3D-printed end effectors offer a flexible, cost-effective case packing solution capable of handling various SKUs.

This case packer improves efficiencies, reliability, and throughput. It has been cost-effectively engineered to support demanding ROI applications.

Speed: up to 60 cycles per minute*

Applications: lunch packs, trays, bottles, pouches, and more

Container types: cases, trays, display cases, totes

* With two robot stations. Depending on product characteristics and machine configuration.

Features

Versatile

- Customized end-of-arm tooling to your product requirements

- Quick connect tooling for quick changeovers

- Ideal for simultaneous handling of different products

Reliable

- Continuous motion for quick, sensitive, and accurate product placement

- Flexible and gentle handling with every pick

Easy to operate

- No flap holders needed due to the robotic motion

- Simple operation with user-friendly interface and quick changeover of packing patterns

- Compact monocoque frame for easy transport

- Integrated electrical power and control panels for quick installation and commissioning

Options

- Multiple robot stations and multi-picks for higher rates

- Stainless steel construction to meet stringent safety standards

- Inspection station with sensor or camera for quality control, part sorting, etc.

- FANUC Robotics iRVision and line tracking technology to track and pick products from high-speed conveyors and place them into trays or cases on the packing line's outfeed side

- Case erector and case sealer

- Label applicator and inkjet printer

- Checkweigher and metal detector

Specifications

Typical footprint From 216′′ L x 91′′ W x 94′′ H (5486 x 2311 x 2387 mm)

(Depending on the configuration)

SpeedUp to 30 cycles per minute per robot

PayloadUp to 13 kg

Power480V 60Hz 3Ph and 208V 60Hz 1Ph

(Other voltages available)

Safety standardsPerformance Level D, Category 3

Operating temperature40 °F to 105 °F / 5 °C to 40 °C

Get pricing and additional information

"End-effector design is a very critical aspect in terms of robot integration into a process and you guys are the best of the best in my opinion at doing that. […] The end result has proven to be very robust and able to withstand the rigor of what's required on a production line of our design."

Gerald Lambert

Executive Vice President of Operations, TW Garner Foods

Need help finding the right case packer?

Call us

We will be happy to answer

your questions

Sales

Parts & technical support

Request a quote

Tell us about your project, and we will reply with solution recommendations