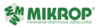

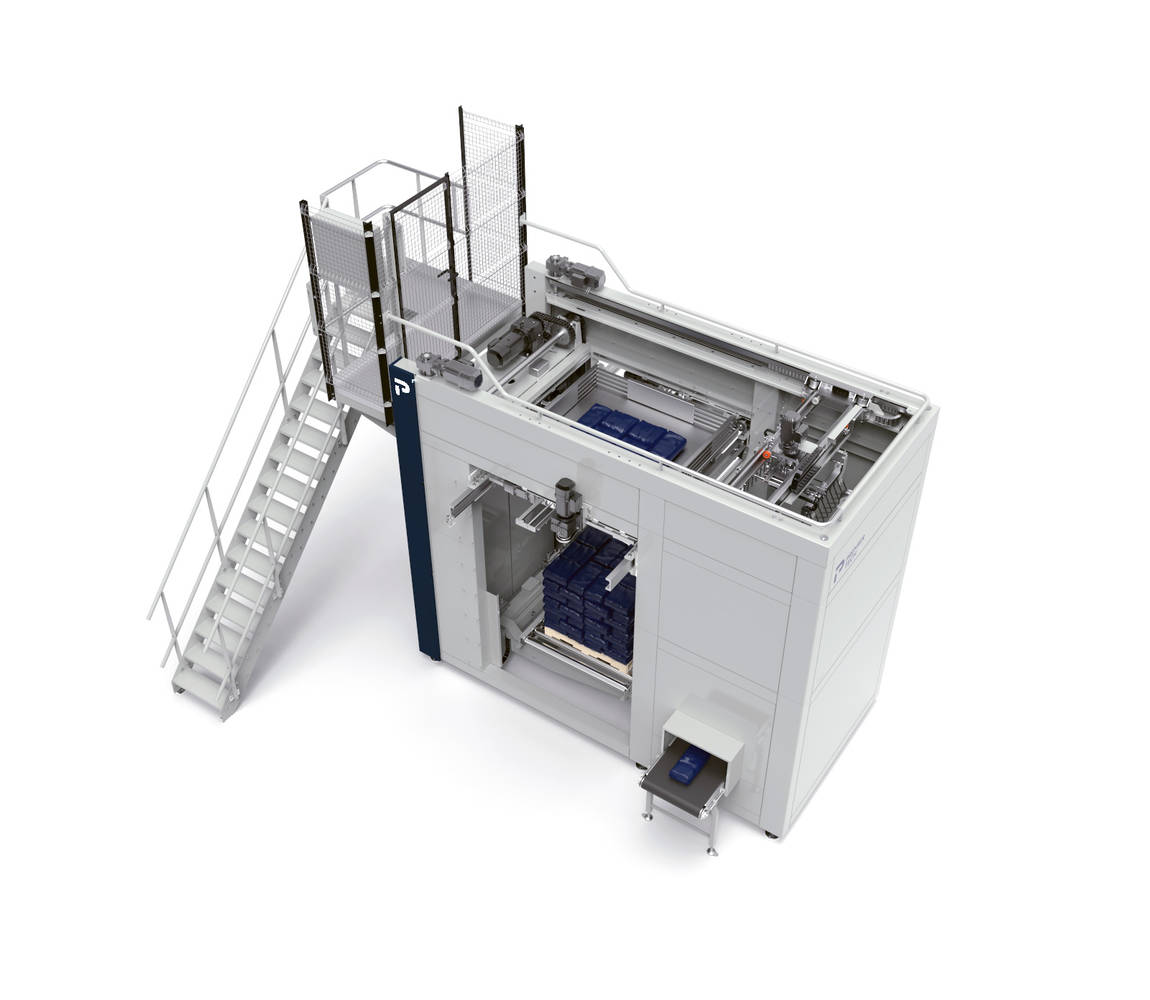

CHRONOS APC SERIESCompact bag palletizer

Available in

Africa, Asia, Europe, Latin America and OceaniaThe APC Series Compact Bag Palletizer uses an ideal combination of robotic and traditional palletizing technologies to optimize the benefits of both systems and create square and sturdy pallets.

The innovative automatic gripper ensures precise bag positioning for maximum stability, while the palletizer's compact design and optional modules make it easy to adapt to your available space.

With options for low-level or high-level infeed conveyor, the APC Series suits any pallet material and bag type for use in all common industries.

Speed: up to 20 per minute (1200 per hour)*

Applications: bags

* With single-pick gripper

Features

Versatile and performant

- Handles wide range of bag sizes and pallet patterns

- Precisely positions bags with automatic gripper techniques

- Overlaps bags and forms and presses layers for increased stability

- Possible to upgrade capacity

High-quality design

- Heavy-duty construction for a longer life span

- Compact design with low-level infeed entry

- Multiple layout configurations

- Optional additional modules and variable layout configurations

- Built-in energy savings (Motor iE3 and weight reduction on gripper)

- Quick installation

Reliable and safe

- Handrails on top frame allow easy and safe access into machine

- Automatic safety latches on elevator

- User-friendly with low maintenance requirements

Options

- Bag preparation systems for even product distribution

- Pallet preparation systems

- Automatic placing of intermediate layers or cover sheets

- Bag quality control systems coupled with rejection systems

- Equipped with printer, labeller, and glue applicator

- Connection to Manufacturing Execution System (MES)

Get pricing and additional information

Need help finding the right palletizer?

Call us

We will be happy to answer

your questions

Sales

Parts & technical support

Request a quote

Tell us about your project, and we will reply with solution recommendations