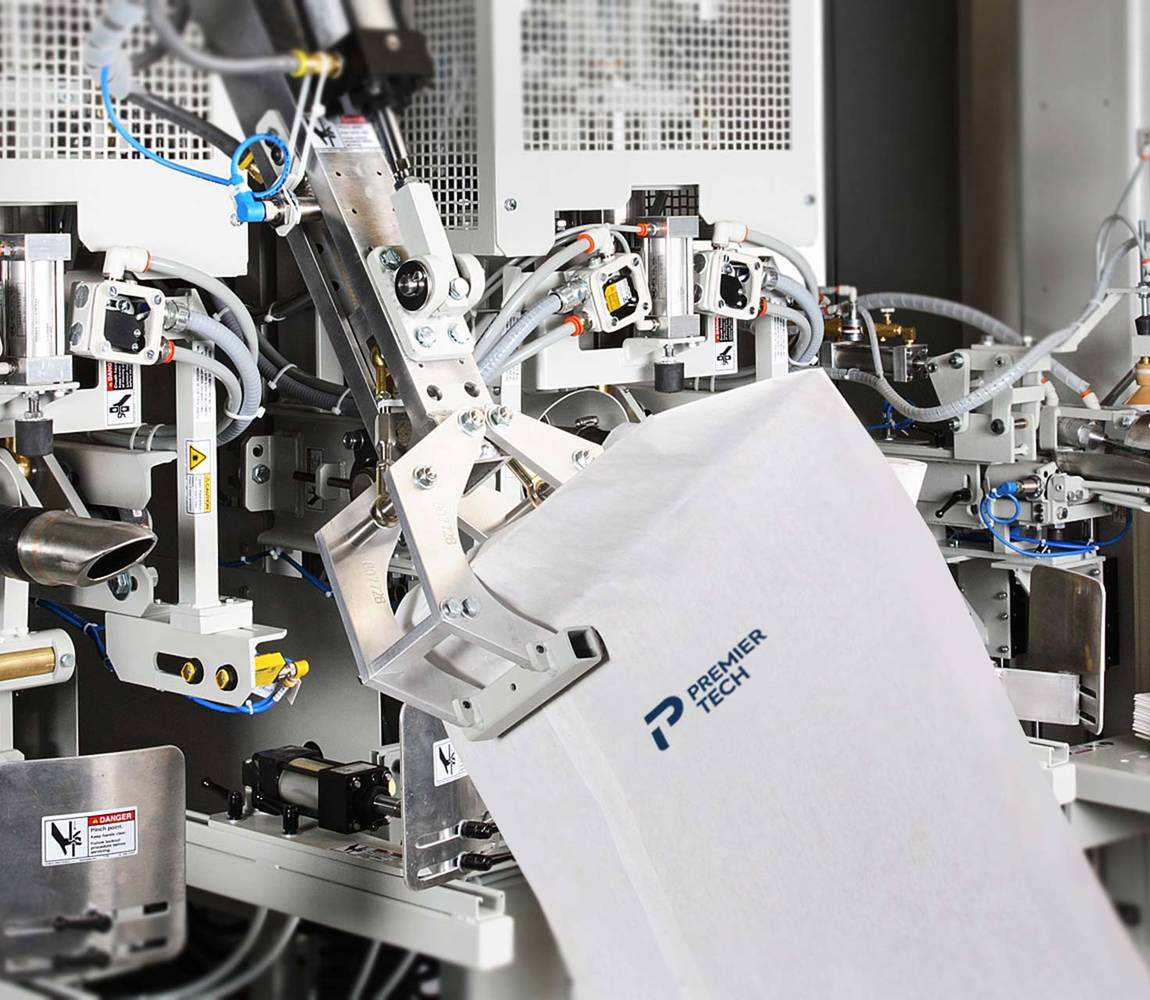

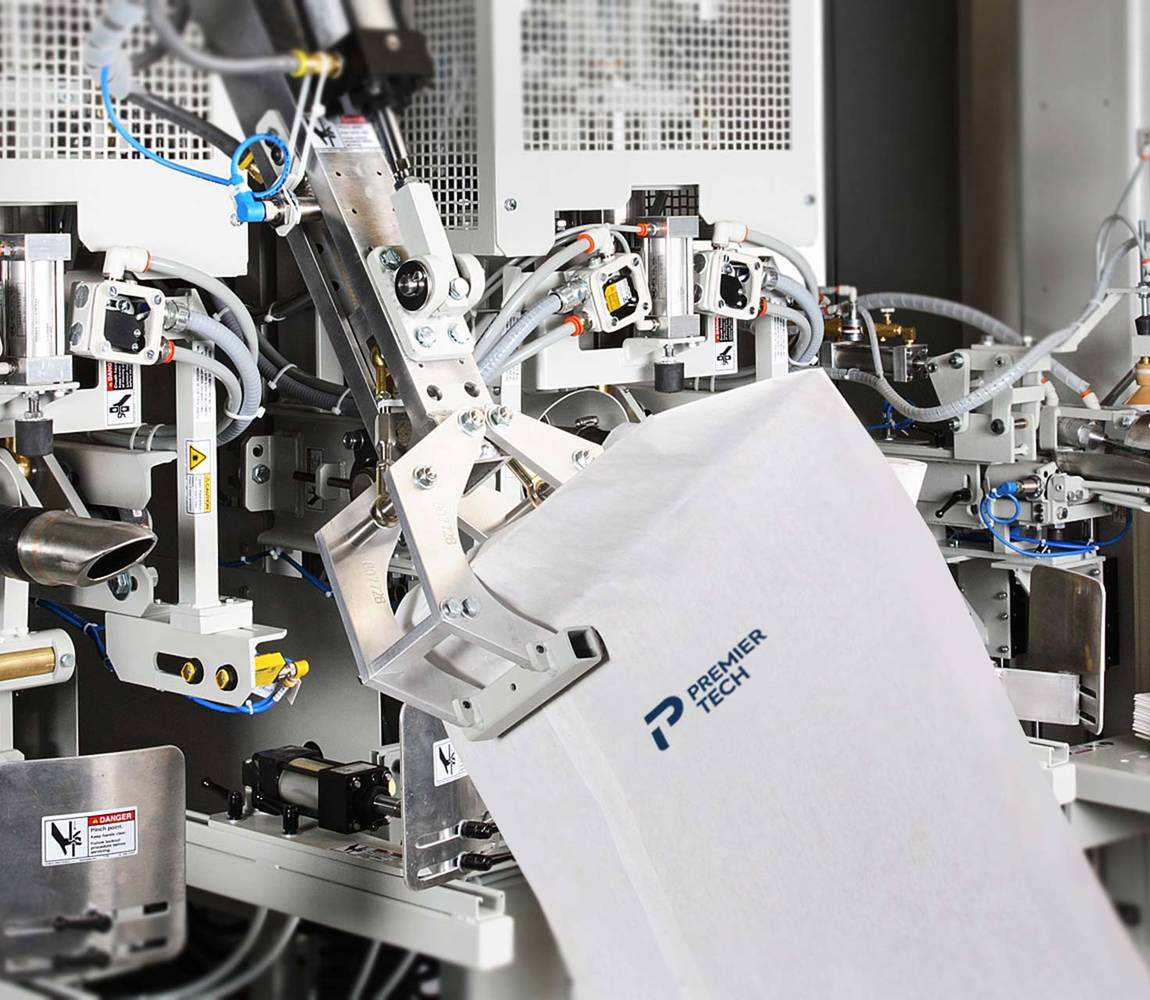

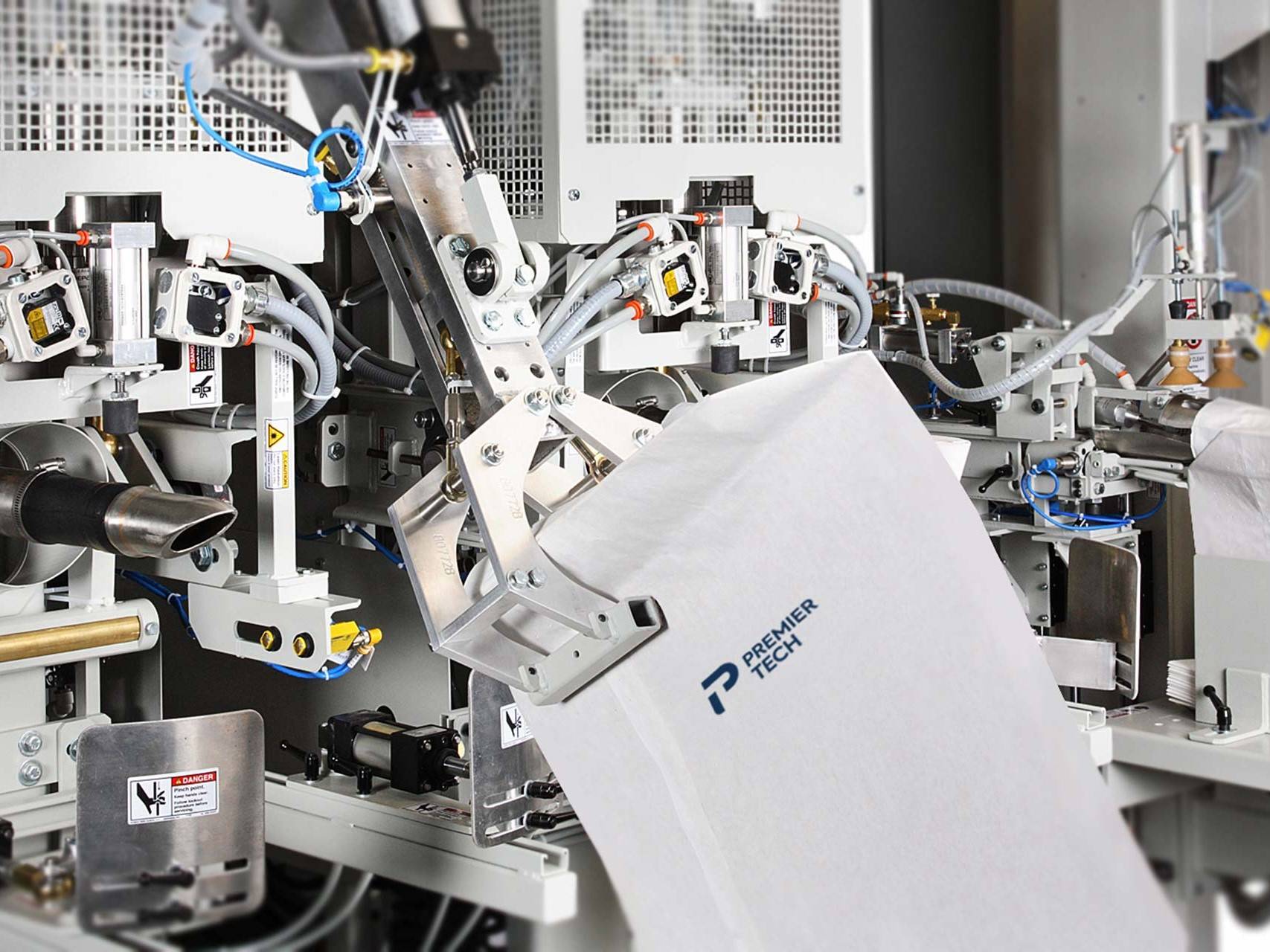

CHRONOS VBH SERIESConventional valve bag applicator

Available in

Asia, Canada & USA, Latin America and OceaniaThe VBH Series (former 509 & 511 Series) conventional valve bag applicators automatically position valve bags on the filling tubes of one, two, three, or four packers.

Both models are easily adjustable for a range of bag widths and lengths. They offer minimal changeover time on multiple bag size operations.

These valve bag placers ensure uninterrupted operation by automatically discarding most defective bags without requiring operator assistance. The simple bag magazine can also be reloaded during production, enabling a seamless process.

Speed: up to 18 bags per minute*

Bag types: valve

*Up to 12 for the 509 Series

Features

Versatility

- Handles all types of valve bags

- Easily adjustable for a range of bag widths and lengths

Performance

- Offers continuous operation by discarding defective bags and continuing without operator assistance

- Simple bag magazine can be reloaded without interrupting production

Design quality

- Solid state electronic programmable controller

- Durable and designed for use in dusty environments

- Positive valve opening as mechanical duckbill enters, opens, and rounds bag’s valve

- Pneumatic claw-style bag gripper replicates control of human hand

509 Series

- Up to 12 bags per minute

- VFD-controlled arm/trolley drive motor for smooth operation

509 Series

- Up to 12 bags per minute

- VFD-controlled arm/trolley drive motor for smooth operation

511 Series

- Up to 18 bags per minute

- Servo motor-controlled arm/trolley drive system for faster operation

511 Series

- Up to 18 bags per minute

- Servo motor-controlled arm/trolley drive system for faster operation

Get pricing and additional information

Need help finding the right valve bag placer?

Call us

We will be happy to answer

your questions

Sales

Parts & technical support

Request a quote

Tell us about your project, and we will reply with solution recommendations