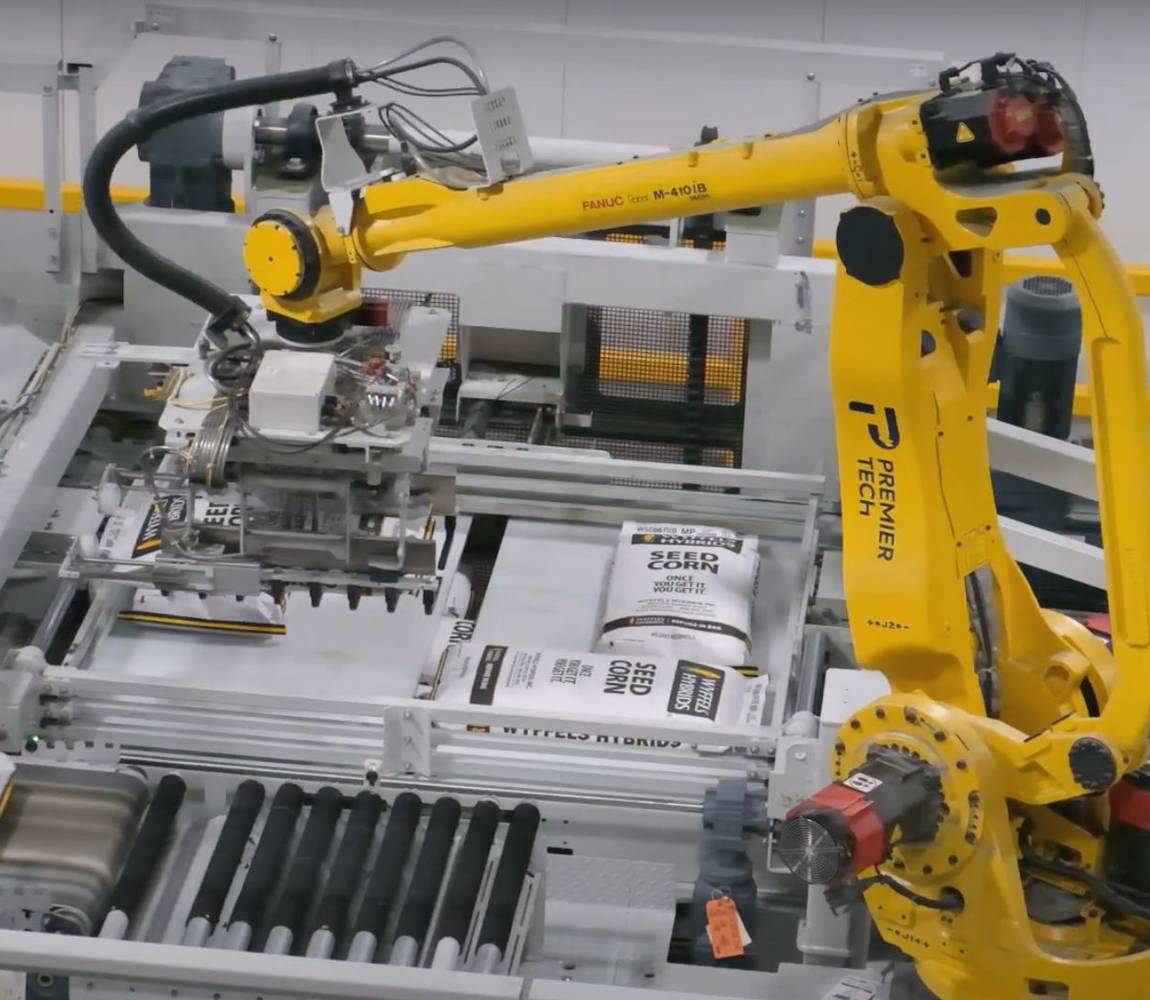

CHRONOS APR-1150Hybrid robotic palletizer equipment

Available in

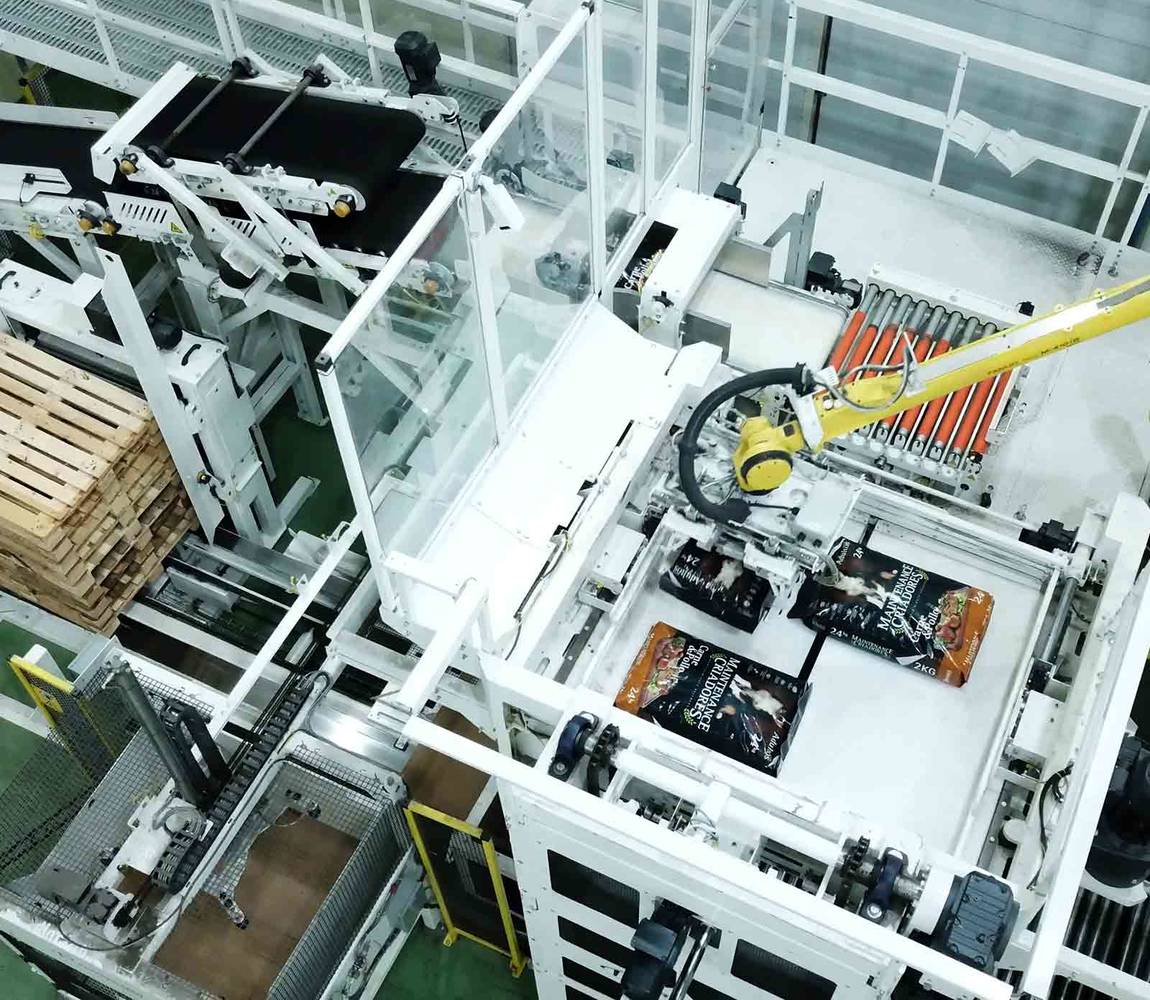

Canada & USA and Latin AmericaThe automated palletizer APR-1150 combines two performant technologies to create high-quality pallet loads: the speed and reliability of our conventional machines with the flexibility of our robotic equipment.

This low-maintenance palletizer is specifically engineered for powdery, granular, or bagged products requiring overlapping, squaring, or compressing.

It is ideal for increasing production quality, capacity, and workspace safety.

Speed: up to 24 units per minute

Applications: bags and bundles

Versatile palletizer for optimal pallet loads

The robotic technology allows the machine to position each unit individually, overlapping them as needed. The conventional palletizer modules square and flatten layers to prevent bag overhang, tears, or damage during shipping.

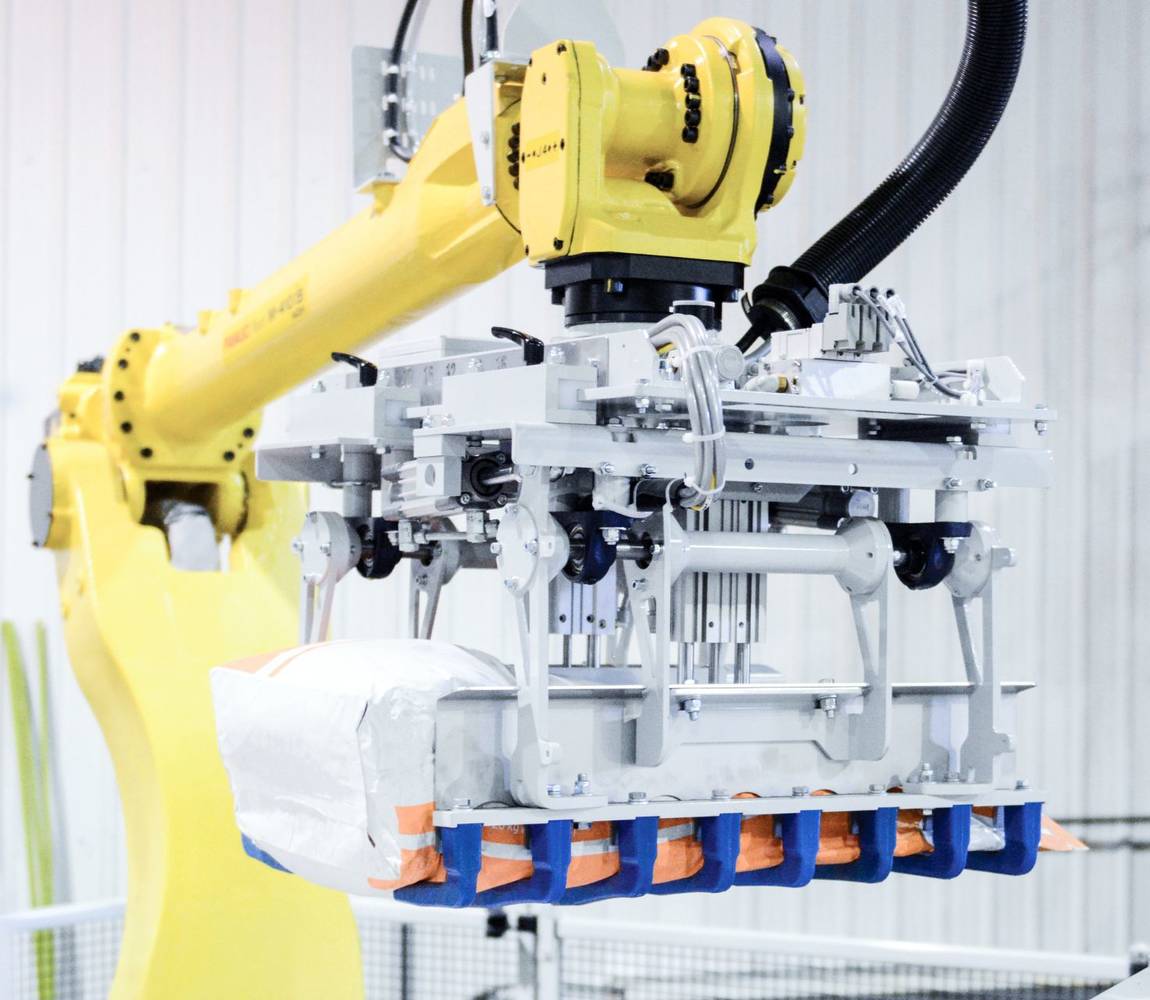

Our mechanical grippers can be manually or automatically adjusted to accommodate bags and bundles of varying dimensions.

- Adjustable finger gripper that can handle open-mouth, valve, pillow, gusseted and gusseted flat bottom bags of various sizes

- Layer squaring and pressing

- Bag overlapping

Built for durable performance

The electric modules enable smooth and quiet operation, compliant with the Occupation Health and Safety (OSHA) noise regulation standards.

The APR-1150 palletizer employs a robotic arm to pick and place individual products, drastically decreasing the number of mechanical components. This translates to reduced maintenance efforts and increased reliability.

- 4000 lb (2000 kg) capacity electric pallet elevator with counterweight for quiet operation

- Rugged steel construction to ensure durability for many years

- Compact design allows shipping in few modules as well as quick installation

- Automatic locking pins on the elevator for safe maintenance

- Automatic pallet dispenser and pusher

Easy to use, easy to run

Operators can easily control the machine via the intuitive human-machine interface. Pattern edition can be carried out quickly through only one point in the HMI, without the complexity of robotic programming.

Conveniently located on the second floor, the HMI offers a global view of the palletizing process to adjust recipes during production.

Moreover, Premier Tech’s palletizing solutions meet all industry safety standards to provide a safe working environment for your employees.

- Human-Machine Interface:

- Intuitive touchscreen with images for easy operations, fault detection, and troubleshooting

- User-friendly layer and pallet building software with pre-stored recipes for quick changeovers

- Available in English, French, and Spanish

- System compliant with Category 3, Performance Level D, ANSI/RIA, 15,06, CSA Z-434-03, and ANSI B155, 1-2006 safety standards

- The operator selects a SKU or pattern on the HMI.

- A pallet is automatically dispensed to the stacking position on the elevator. A sheet can be applied if required.

- Bags enter the top of the machine via a high-level infeed conveyor and are released one by one.

- The robot’s end-effector takes a unit, orients, and places it accurately on the stripping plates.

- The process is repeated until a complete layer is formed.

- The elevator raises the pallet while the four alignment bars maintain the layer in place. The stripping plates open, and units are deposited on top of the load.

- The elevator is then lowered, and the plates close. If required, the layer can be compressed against the plates to level and stabilize it even further.

- When the pallet load is complete, the elevator lowers, allowing it to exit the cell.

Additional options

The APR-1150 hybrid palletizer can be equipped with various options to fit your end-of-line requirements:

- Bag preparation systems to level or flatten bags

- Leak, weight, and metal detection systems coupled with a rejection conveyor to remove non-compliant bags

- Automatic product changeovers

- Servomotor or pneumatic-powered gripper for automatic bag width adjustment

- Quick-connect power and control cabling for faster installation in your facility

- Integration with concurrent stretch wrapping machines and third-party suppliers (labelers, printers, etc.)

- Automatic slip/top sheet dispenser

- Exit conveyor

Get pricing and additional information

Partnering in your success

Premier Tech offers unbeatable services and support throughout the lifecycle of your equipment.

Experts in packaging since 1989

Experts in packaging since 1989

Effective engineering capabilities

Effective engineering capabilities

Need help finding the right palletizer?

Call us

We will be happy to answer

your questions

Sales

Parts & technical support

Request a quote

Tell us about your project, and we will reply with solution recommendations