Wide variety of palletizing solutions

Our team gathers every day with one goal in mind: to create an experience like no other for our clients. Through our passion, energy, expertise, and commitment, we strive to have a meaningful impact and put our technology at the service of your industry.

Palletizing technologies

We offer both standardized and customized solutions that are best adapted to cover your current and future needs.

Robotic palletizing

Cases : Up to 84 units / minute

Bags : Up to 40 bags / minute

- Robot palletizers are made up of fewer mechanical components which allows for less frequent down times and superior reliability.

- Various end-effectors are available which give the robot great versatility to handle different products.

- A robotic palletizer can handle one or more units at a time according to pallet configuration, and forms multiple layers on a pallet after picking the products off a conveyor.

- There are many advantages to choosing an automated palletizing solution. Among others, companies usually prefer that kind of technology for the increased safety and reduced labor costs it brings.

- Another unique benefit is that it can handle different SKUs on the same line thanks to vision and sensors.

Robotic palletizing

Cases : Up to 84 units / minute

Bags : Up to 40 bags / minute

- Robot palletizers are made up of fewer mechanical components which allows for less frequent down times and superior reliability.

- Various end-effectors are available which give the robot great versatility to handle different products.

- A robotic palletizer can handle one or more units at a time according to pallet configuration, and forms multiple layers on a pallet after picking the products off a conveyor.

- There are many advantages to choosing an automated palletizing solution. Among others, companies usually prefer that kind of technology for the increased safety and reduced labor costs it brings.

- Another unique benefit is that it can handle different SKUs on the same line thanks to vision and sensors.

Conventional palletizing

Cases : Up to 80 units / minute

Bags : Up to 40 bags / minute

- Conventional palletizers can produce very high and stable pallets.

- Having this type of equipment requires no specialized knowledge other than traditional mechanics and pneumatics therefore less training is needed.

- There are two types of conventional palletizers, low level and high level palletizers.

- The main difference between the two types is that with a high level palletizer, the products are also brought by a conveyor, but instead of raising or lowering each completed layer for discharge onto a pallet, it is the pallet that is raised or lowered while product layers remain stationary.

Conventional palletizing

Cases : Up to 80 units / minute

Bags : Up to 40 bags / minute

- Conventional palletizers can produce very high and stable pallets.

- Having this type of equipment requires no specialized knowledge other than traditional mechanics and pneumatics therefore less training is needed.

- There are two types of conventional palletizers, low level and high level palletizers.

- The main difference between the two types is that with a high level palletizer, the products are also brought by a conveyor, but instead of raising or lowering each completed layer for discharge onto a pallet, it is the pallet that is raised or lowered while product layers remain stationary.

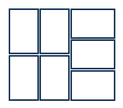

Pallet patterns

The right pallet pattern will allow you to gain overall efficiency. Changeovers with our conventional and robotic palletizers are made easy thanks to our user-friendly interfaces and stored recipes. Displayed below are a few examples of available pallet patterns.

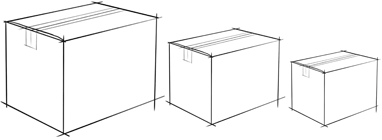

Containers we can handle

We are used to working with any type of container, no matter the shape, and size. We can handle small, medium and large scale types of containers. Here are a few examples:

Client testimonials

Grain Craft

Robotic palletizing

"Using Premier tech (equipment) came naturally to us because we were able to easily manipulate our lines, put our lines into operation, we were able to palletize all of our product that we make here and we're very diverse [...]."

Clint Church, Plant Manager

Maker’s Mark

Conventional palletizing

“On the old palletizers [...] you’d have the arm and the shoulders, and your back would strain, with this you stand, and you watch so that is definitely an improvement.”

Terry Gabhart, Bottling Team Member

North Dakota Mills

Conventional palletizing

"We need our pallets to be real square, nicely stacked on the pallet so it fits into rail cars and the trucks and so our customers can stack them in their warehouse and it definetely does the job for us [...]"

David Klinger, Warehouse Superintendent

© Premier Tech Ltd., 2019-2025. All Rights Reserved.