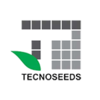

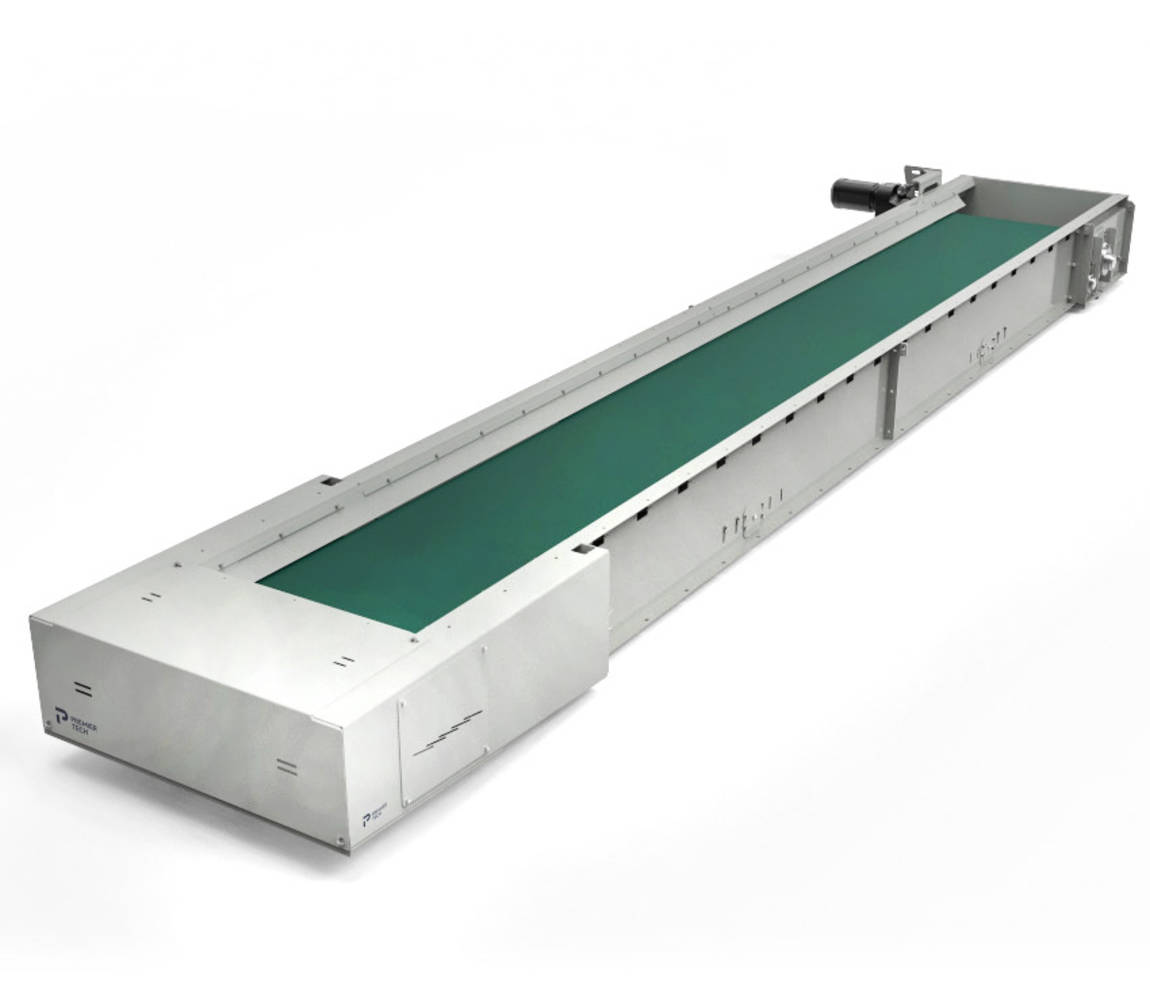

Bulk conveyor

Disponível em

Africa, Canada & USA, Europe, Latin America and OceaniaBelt and chain conveyors can be used to collect, transport or stockpile a wide variety of bulk materials.

Whether you are looking for a troughed belt, a flat bed, a cleated belt, a drag chain or a steel apron conveyor, Premier Tech offers a complete range of bulk conveyor lines for standard or heavy-duty applications

Applications: bark, compost, manure, mulch and mixes of products such as reed sedge, peat moss, topsoil, sand and wood shavings

Features

Low maintenance and easy to clean

- Shaft-mounted gear motor for less maintenance

- Belt support and skirting for improved sealing and spillage control

- Tensioned cleaning scraper

Reliable

- Lagged head pulley

- Return roller(s) supporting the belt

High quality design

- Modular 10’ (3 m) sections for easy assembly and future modification

- Easy belt tensioning at the tail

Obtenha preços e informações adicionais

Need help finding the right mixing equipment?

Ligue para nós

Ficaremos felizes em responder suas

perguntas

Vendas

Peças e suporte técnico

Obtenha mais informações

Conte-nos sobre seu projeto e responderemos com recomendações de soluções

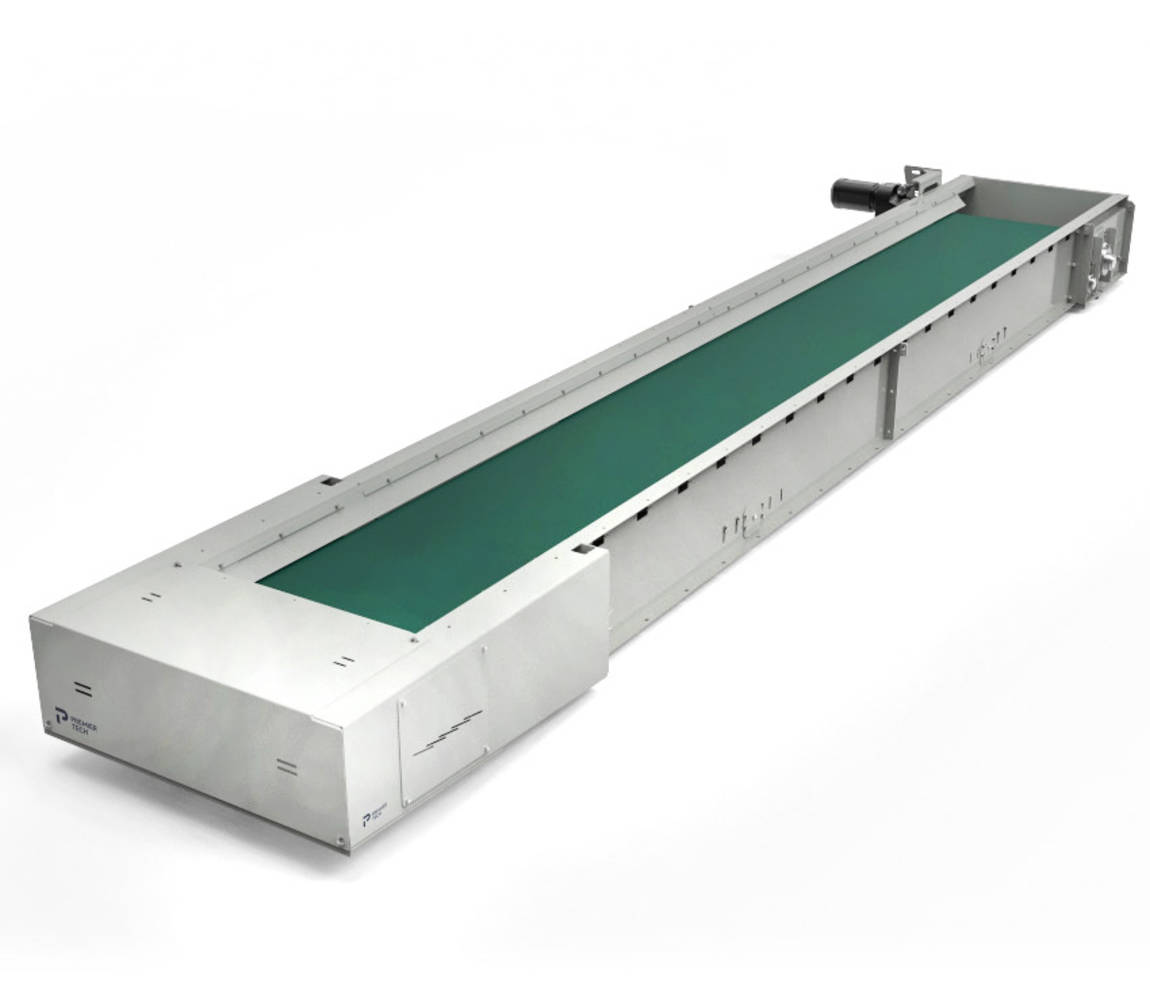

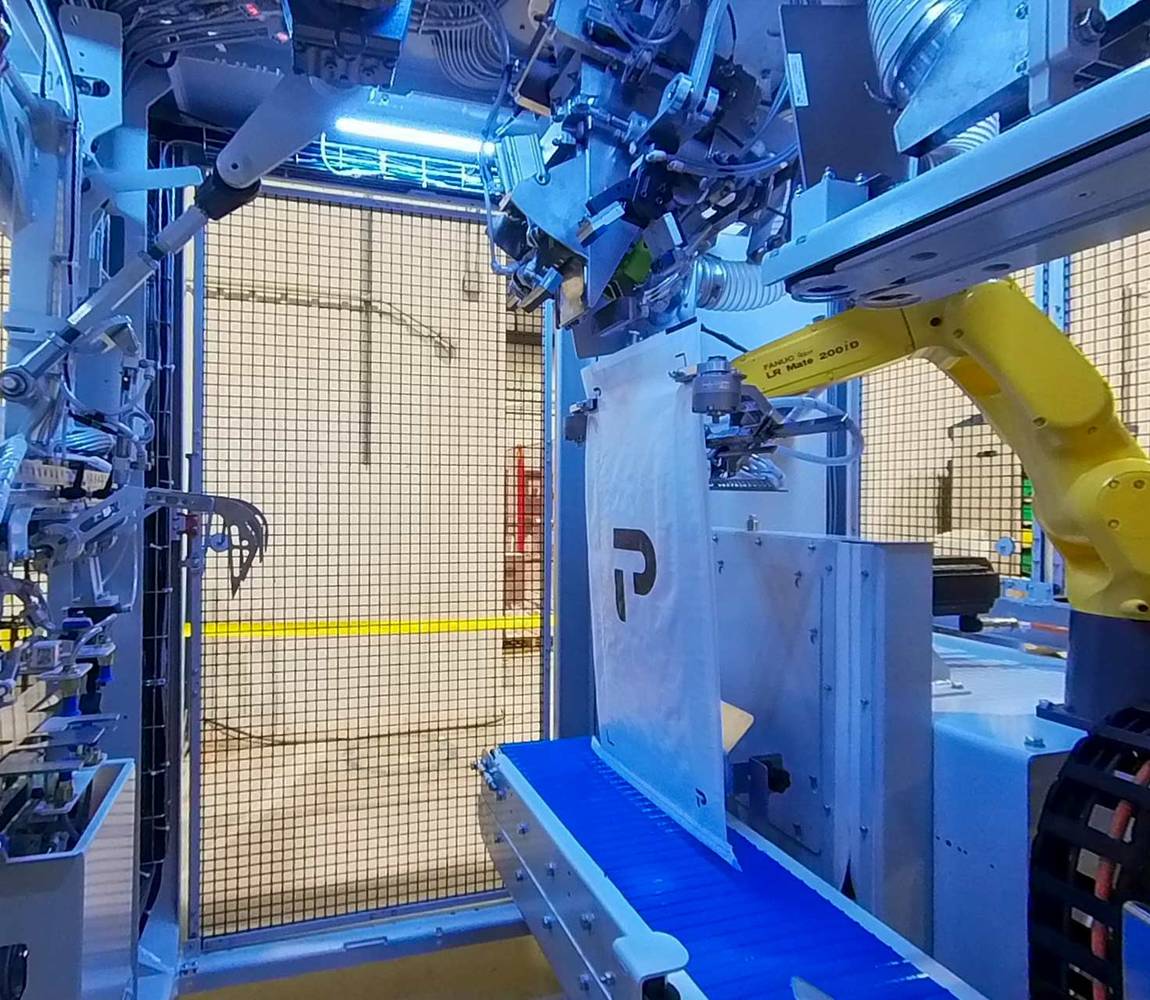

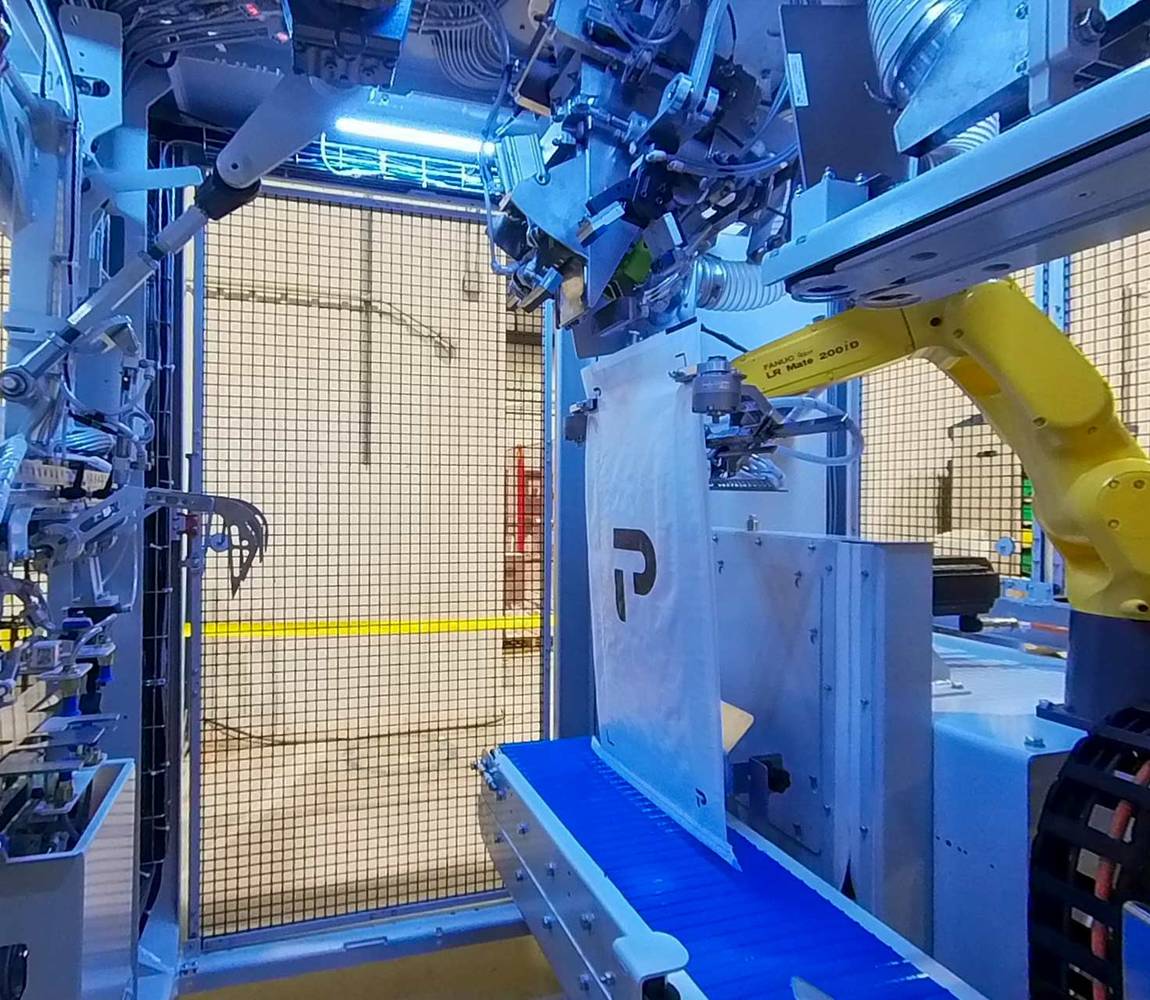

CHRONOS OMR SERIESVersatile robotic open-mouth bagger

Disponível em

Africa, Canada & USA, Europe, Latin America and OceaniaThe OMR Series features patented technologies and robotics for a simple, reliable, and low-maintenance bagging solution.

These baggers, offered in two models, efficiently pack various free-flowing materials from multiple industries, such as pet food, seeds, animal feeds, fertilizers, corrosive materials, and more.

These versatile open-mouth bagging machines also handle many bag materials and accommodate different sizes with quick and simple adjustments.

Speed: up to 20 bags per minute (1200 per hour)*

Bulk materials: granules, powders, fibers, flakes, pellets, and coarse aggregates

Bag types: gusseted, pillow, and block bottom

Bag materials: paper, PE, laminated and non-laminated woven PP

Bag weight: 11 to 110 lb (from 5 to 50 kg)

* Depending on the application, bag characteristics, and machine configuration

Features

Innovative

- Patented technologies for precise and consistent bag handling

- Automatic bag placer and robotic bag transfer to the closing system

- Separates woven PP bags efficiently

- Bag detection on the filling spout to prevent product spillage without interrupting the bagging process

Versatile

- Handles various bag sizes and materials

- Adapted to harsh and dusty environments

- Multi-language HMI with quick automatic bag size changeovers

- Parts in direct contact with the product are made of stainless steel 304

Compact

- Compact footprint and low headroom suited for restricted packaging rooms

- Ships in a few modules for quick installation and start-up

- Large access doors provide easy operations and safe maintenance

Options

- Automatic adjustment on the bag magazine

- Servo-driven bag dispenser, placer, and spout for increased precision and speed

- Dust control spout and collection system

- Filling spout with gusset reformer

- Compatible with sealers, sewing, and pinch-top closing machines

- Back kicker or line turner

- Various bag identification options

- Wash down parts for easy cleaning

Specifications

Typical footprint up to 137" L x 101" W x 86" H (3470 x 2552 x 2170 mm)1

Bag dimensions 11–24" W (279–610 mm) x 20–44" L (508–1118 mm)1

Bag magazine capacity up to 300 bags2

Electrical requirement 460 V / 3Ph / 60 Hz

Operating temperature 40 °F to 95 °F / 5 °C to 35 °C

1 Depending on the model

2 Depending on the model, bag thickness, and number of bag piles

OMR-1130

(Previously PTW-1200)

- Up to 20 bags per minute (1200 per hour)

- Handles laminated and non-laminated woven PP, PE, and paper bags

- Increased capacity and precision on main movements:

- Servo-driven bag dispenser

- Motorized bag placer

- Servo-driven settling conveyor

- Additional accumulation conveyor

OMR-1130

(Previously PTW-1200)

- Up to 20 bags per minute (1200 per hour)

- Handles laminated and non-laminated woven PP, PE, and paper bags

- Increased capacity and precision on main movements:

- Servo-driven bag dispenser

- Motorized bag placer

- Servo-driven settling conveyor

- Additional accumulation conveyor

OMR-1130

(Previously PTW-1200)

- Up to 20 bags per minute (1200 per hour)

- Handles laminated and non-laminated woven PP, PE, and paper bags

- Increased capacity and precision on main movements:

- Servo-driven bag dispenser

- Motorized bag placer

- Servo-driven settling conveyor

- Additional accumulation conveyor

OMR-1130

(Previously PTW-1200)

- Up to 20 bags per minute (1200 per hour)

- Handles laminated and non-laminated woven PP, PE, and paper bags

- Increased capacity and precision on main movements:

- Servo-driven bag dispenser

- Motorized bag placer

- Servo-driven settling conveyor

- Additional accumulation conveyor

OMR-1130

(Previously PTW-1200)

- Up to 20 bags per minute (1200 per hour)

- Handles laminated and non-laminated woven PP, PE, and paper bags

- Increased capacity and precision on main movements:

- Servo-driven bag dispenser

- Motorized bag placer

- Servo-driven settling conveyor

- Additional accumulation conveyor

OMR-1130

(Previously PTW-1200)

- Up to 20 bags per minute (1200 per hour)

- Handles laminated and non-laminated woven PP, PE, and paper bags

- Increased capacity and precision on main movements:

- Servo-driven bag dispenser

- Motorized bag placer

- Servo-driven settling conveyor

- Additional accumulation conveyor

Obtenha preços e informações adicionais

"Premier Tech, I believe, had the number 1 bagger that we looked at."

Jon Wilson

Production Supervisor, United Animal Health

Need help finding the right open-mouth bagger?

Ligue para nós

Ficaremos felizes em responder suas

perguntas

Vendas

Peças e suporte técnico

Obtenha mais informações

Conte-nos sobre seu projeto e responderemos com recomendações de soluções