SpeedAC iQ: Revolutionizing the Weighing Industry

Steve Santerre and his team were commissioned to develop a weight controller more efficient than its predecessors. The main challenges of the project were simplifying the interface and ensuring the quality of the new functions—changes that would have a significant impact on the day-to-day work of future users.

The aims of the project were to reduce the number of actions required on the interface and to minimize the potential for errors by implementing new features.

“The big challenge was to develop a product with profitable new features for our customers while also ensuring a user-friendly and intuitive operating experience.” Steve Santerre, Automation Programming Coordinator

SIMPLE NAVIGATION

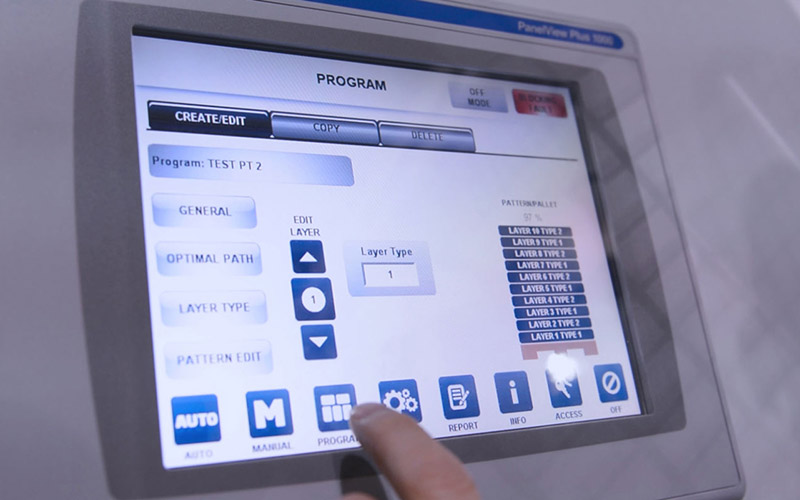

The team had to develop a new interface equipped with a touch screen, a color menu as well as multi-language capabilities. Navigation and programming settings needed to be intuitive, requiring virtually no reading when the operator is required to look up or program settings.

“It was important for us to develop a machine that allows the operator to be independent without having to complete 60 hours of mandatory training in order to be able to work the machine. This is an important issue for our customers.” Steve Santerre, Automation Programming Coordinator

AN INTELLIGENT WEIGHT CONTROLLER

Once the work on the interface was completed, the team set about tackling the “brain” of the SpeedAC iQ. The number of manual adjustments needed to be reduced significantly to ensure the weight controller could respond to instructions efficiently. The “Autotune” function now allows product throughput to be monitored and continuously adjusted in order to achieve the rate and production precision objectives set by the operator. The team worked on developing a powerful algorithm that performs intelligent bag filling. All the user has to do is enter the weight instructions and the job is done. Thanks to a new function, it is also now possible—and indeed very simple—to integrate additional equipment (conveyors, lights, etc.) directly into the SpeedAC iQ interface.

PREVENTING AND RESOLVING PROBLEMS

The previous version of the weight controller did not offer a backup option in the event of problems with loss or damage to the program. To minimize the risk, the programs are not only preloaded and easy to install to begin with, but can also be backed up and restored using a USB stick in the event of problems.

If assistance is required, the weight controller provides access to remote troubleshooting via the Internet with Premier Tech technicians. They can access the program, identify the problem and resolve it automatically.