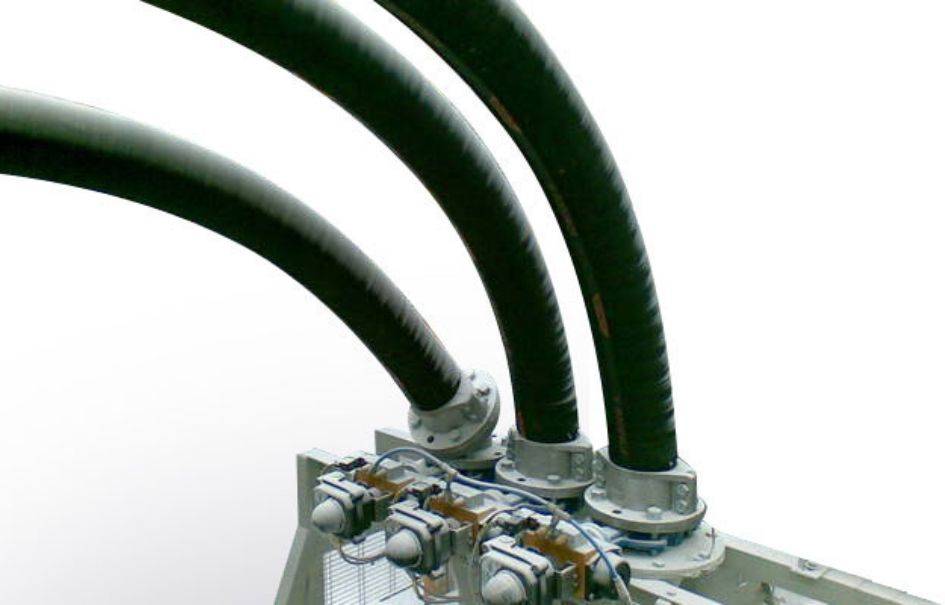

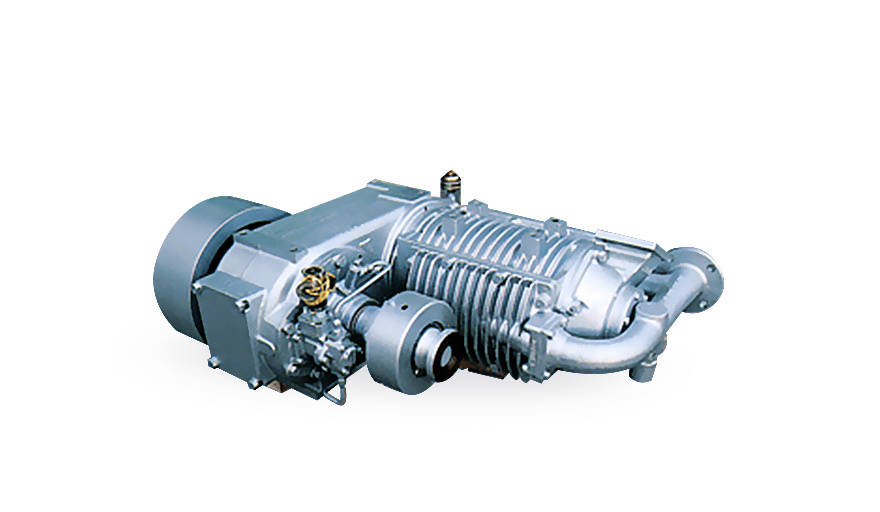

Pneumatic conveying systems

Moving granular or powdered dry bulk materials efficiently can be challenging. The decision can involve several factors, including required throughput, conveying distance, available space, efficiency requirements, and budget constraints.

Fortunately, our range of pneumatic conveyors can handle various materials, including abrasive, fragile, cohesive, or combustible substances. With Kockums’ extensive experience in Australia, we can guide you in choosing the most suitable pneumatic conveyor.

Whether you need a vacuum, air, dense, or lean phase conveying system, we can supply equipment for transferring 100 kg/h to 300 tonnes/h and nearly 1 km long.

How we partner in your success

With the technical innovation and expertise gained through our legacy brand Kockums, we are committed to providing pneumatic conveying solutions tailored to your needs to improve operational efficiency.

Lifetime warranty

Guaranteed lifetime warranty as well as on-site visits from knowledgeable local technicians

Lifetime warranty

Guaranteed lifetime warranty as well as on-site visits from knowledgeable local technicians

Technical support

Qualified technical support available 24/7 for remote troubleshooting

Technical support

Qualified technical support available 24/7 for remote troubleshooting

Training

Practical operator training that ensures a smooth transition to robotics

Training

Practical operator training that ensures a smooth transition to robotics

Need help choosing the right pneumatic conveyor?

Request a quote

Tell us about your project, and we will reply with solution recommendations