Maintenance Training Lab

Gain ownership of your equipment with this maintenance training program hosted at one of our facilities.

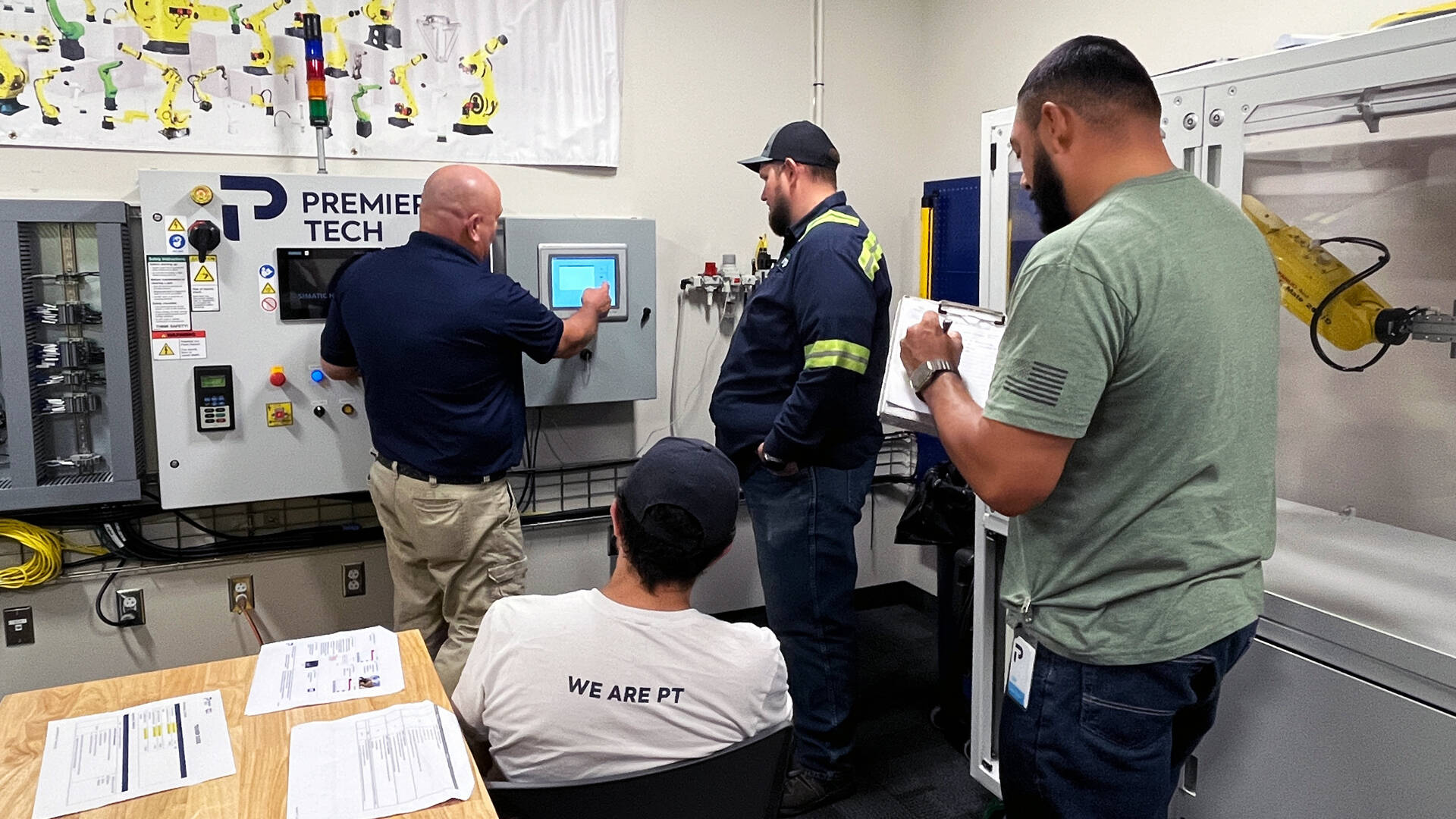

Empower your team at the Maintenance Training Lab

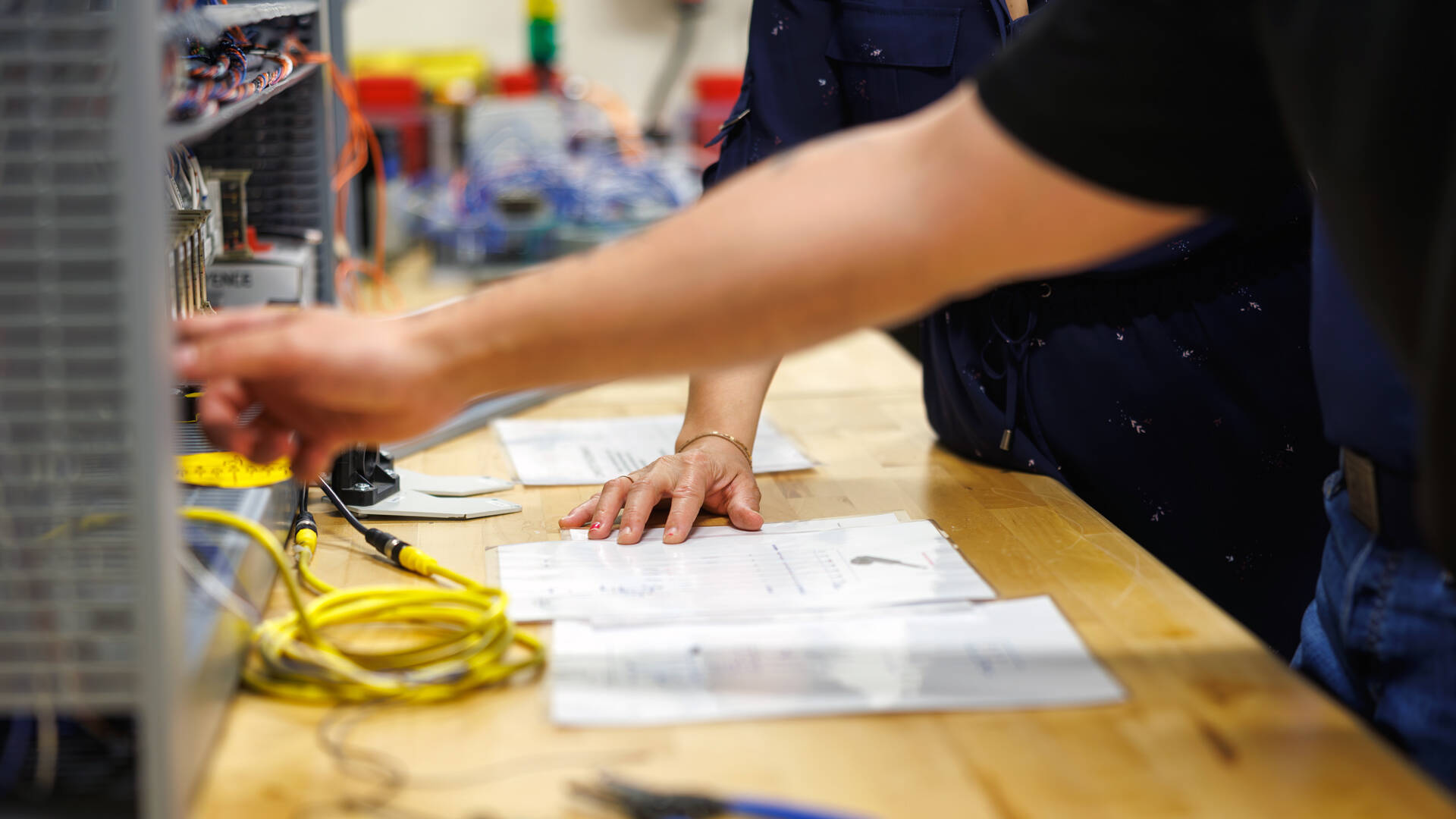

Our Maintenance Training Lab offers unparralleled hands-on experience. Equip your team with the skills needed to excel in their roles. Unlock greater uptime and consistency, fewer delays, and more efficient operations with targeted training.

Program Purpose

Key objectives

- Read and interpret electrical and pneumatic drawings

- Identify key components

- Understand and troubleshoot systems

Training without downtime

Training takes place at a Premier Tech facility.

Access state-of-the-art equipment and resources.

Receive dedicated support from expert trainers throughout the program.

Improve content retention

Boost job satisfaction and retention rates.

Build a skilled, efficient, and committed team.

Maintain top performance standards.

Program summary

Location: At a Premier Tech’s a facility

Participants: Up to four maintenance team members from one or different plants

Duration: 8 hours of live virtual training, 3 to 4 days at the lab

Included material: Workbook

Program agenda

This maintenance training program lasts between 4 and 5 days, including 8 hours of remote training before your visit to the laboratory. Since the day dedicated to robotics is optional, you can expect 3 to 4 days of on-site training in laboratory learning environment located in one of our facilities.

Online

Modules

These online modules must be completed a few days before visiting the Technical Training Lab. The course is designed to be taken in four sessions of two hours:

- Understand electrical concepts and components

- Read pneumatic drawings

- Understand pneumatic concepts and components

- Read electrical drawings

Day 1 :

Electric

Participants will read electrical drawings, identify and troubleshoot electrical components, and understand motor nameplates for protection adjustments. The key areas covered on day 1 include:

- Understand electrical circuits

- Work with AC Motors and VFD

- Work with Conveylinx and DC Motors

Day 2 :

Pneumatic & mechanic

Learners will read pneumatic drawings and identify various pneumatic components and their functions. Troubleshooting pneumatic components is a key skill covered, along with understanding the vacuum principle. Key areas covered on day 2 include:

- Work with pneumatic circuits

- Troubleshoot pneumatic components

- Make mechanical adjustments

Day 3 :

Robotic (optional)

This one-day module is optional if you do not operate robotic equipment at your plant.

Attendees will identify the main components of a robot and define robot location and axes. Skills include operating the robot manually and setting up a position register. This day is dedicated to hands-on robotic workshops covering:

- Configure IP addresses

- Differentiate robot I/O

- Make backups

- Troubleshoot common robot problems

- Create patterns using Pattern Expert

Day 4 :

Automation

- Participants will focus on automation workshops.

- Identify different components of an automation system

- Troubleshoot using the I/O display on the HMI

- Identify network modules

- Assign IP addresses for network modules

Get started with training

Contact us today to learn more about our Maintenance Training Lab programs and how to enroll.