- Home

- Products

- Palletizing equipment

- Robotic palletizers

- Entry-level semi-automatic palletizing robot

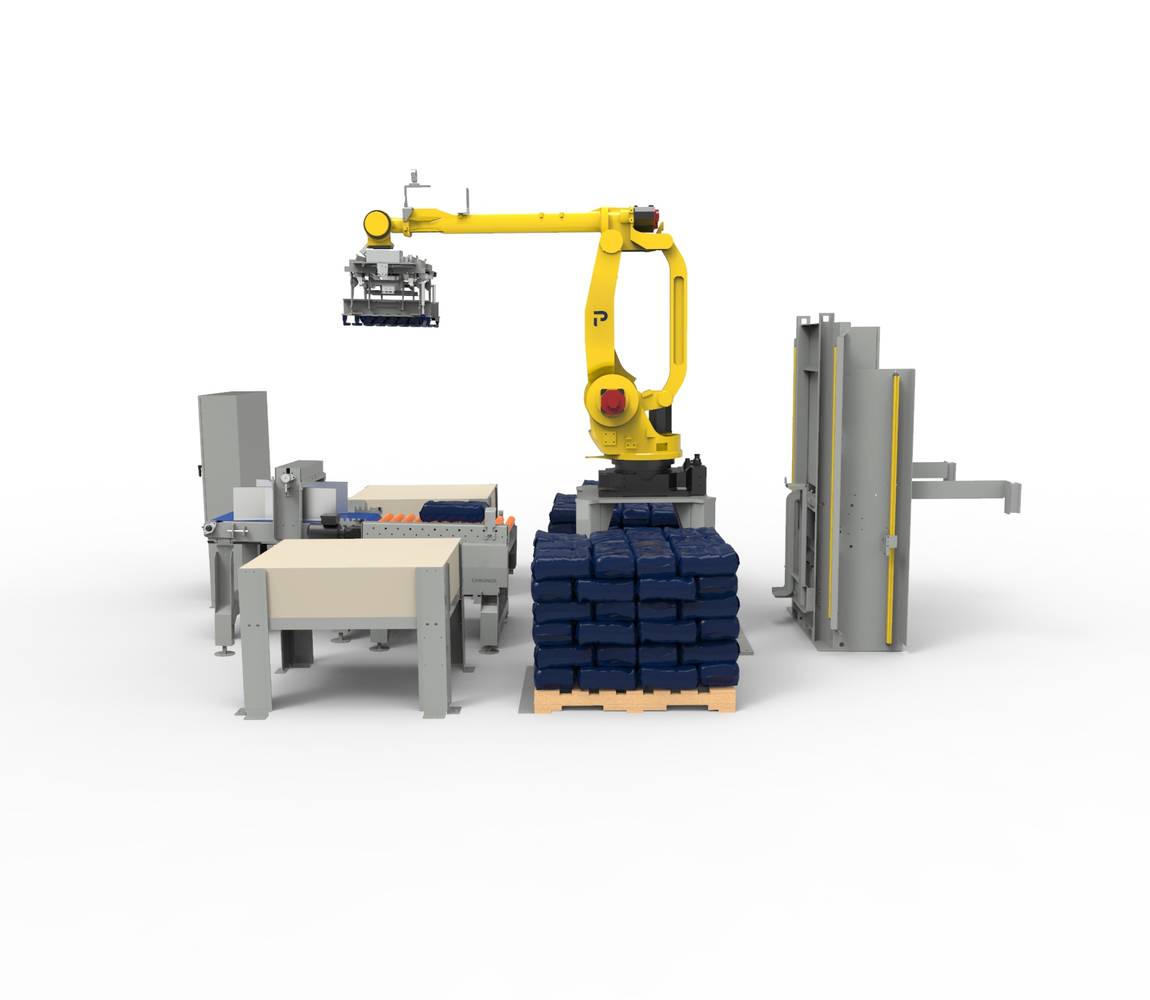

CHRONOS RPL-1000 SERIESEntry-level semi-automatic palletizing robot

Available in

Canada & USA and Latin AmericaThe RPL-1000 Series is our most affordable and simple robotic palletizing cell from our RPL Series, and an ideal choice when getting started with robotics.

Engineered to use the smallest possible space in your facility, it builds loads directly on a pallet on the floor from a single production line. When completed, the lift operator enters the cell to transfer the pallet safely.

Flexible and easy to maintain, these robotic palletizers can handle containers of various shapes and sizes with speed and reliability.

Speed for cases: up to 20 per minute (1200 per hour)

Speed for bags: up to 19 per minute (1140 per hour)

Applications: bags, bales, bundles, cases, trays, and totes

Features

Cost-effective

- Robotic stacking of units with manual sheet and pallet handling

- Compact and modular layout to fit in confined spaces

- Up to three pallets per stacking position can be housed, reducing the operator's time spent in the cell

Highly safe

- Robust end effector adapted to your applications

- Flexible and reliable FANUC robot with Dual Check Safety

- Safety fences and light curtains to keep your employees safe

Ease of use

- Built with high-quality components for low-cost maintenance

- Quick installation and commissioning

- User-friendly layer and pallet building software, Pattern Expert, with pre-stored recipes for quick changeovers

Options

- Finger, vacuum, or clamp end effector to fit your product’s unique requirements

- Slip, top, or tier sheet handled by the robot for increased autonomy

- Stainless steel components for food industry requirements

- Integration with third-party printers, labelers, pallet traceability, and more

Additional options for bags

- Rejection conveyor for non-compliant bags

- Automatic bag width adjustment

- Weight check system

RPL-1111

- Picks units from 1 production line

- Places them on 1 palletizing station on the floor

RPL-1111

- Picks units from 1 production line

- Places them on 1 palletizing station on the floor

RPL-1112

- Picks units from 1 production line

- Places them on 2 palletizing stations on the floor

- Allows for continuous stacking activities while the operator removes the load from the cell

RPL-1112

- Picks units from 1 production line

- Places them on 2 palletizing stations on the floor

- Allows for continuous stacking activities while the operator removes the load from the cell

Get pricing and additional information

“Nothing affects it. From Monday to Friday, the palletizing robot is always present and consistent. It's the consistency that reveals the actual value of the equipment.”

Bruno Tremblay

Co-owner, Ferme Walter Tremblay et Fils