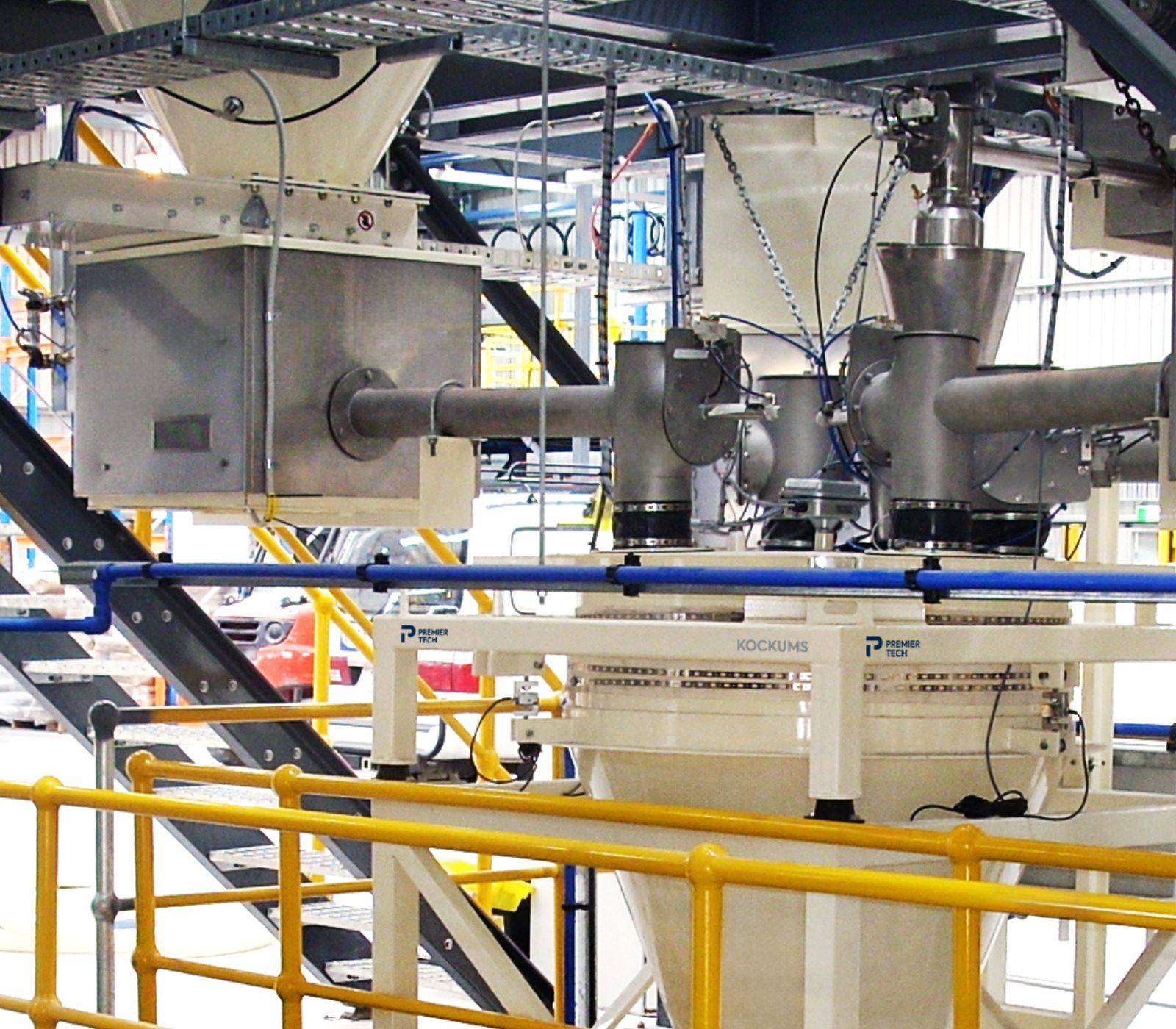

KOCKUMS

Batch Weighing System

Available in

Asia, Canada & USA, Latin America and OceaniaWe have been supplying single and multi-ingredient recipe batching systems to the process industry for several decades.

A good recipe batching system is not just about the equipment. It is about understanding the importance of each ingredient within the recipe and the associated quality requirements of the client.

Once we understand the application, we can choose the correct equipment and guarantee expected rate and accuracy.

Dosing devices may be a simple three-position butterfly valve, rotary valve, screw conveyor, or an “Autoflex” Flexible Wall Feeder, ideal for materials prone to bridging and rat holing.

Monitoring is usually by weight and utilizes either "Loss of Weight" or "Gain in Weight" methods, depending on the accuracy and batching cycle time. Volumetric dosing is also a possibility for lower-accuracy applications.

Bulk materials:flakes, granules, pellets and powders

Features

Reliability

High accuracy and repeatability of ingredient dosing ensuring the final recipe remains consistent every time.

Usability

Designs available to allow for Ease of Changeover between different ingredients with minimum downtime.

Versatility

Dosing systems with fully adjustable speed and auger sizes to adjust through-put and accuracy.