CHRONOS 2001-2002Conveyor mounted ultrasonic sealer

Available in

Africa, Asia, Canada & USA, Europe, Latin America and OceaniaThe conveyor-mounted ultrasonic sealer is a patented solution that seals valve bags using ultrasonic energy instead of heat. This results in a cleaner weld without causing any product degradation.

There are two models available that can seal various products in valve bags. They are compatible with Premier Tech air, auger, and impeller packers.

Both models use the same rugged PINSONIC ultrasonic components that are used in other models of Premier Tech’s ultrasonic sealers.

Speed: up to 20 bags per minute

Bag types: valve bags

Bag materials: paper

Features

High design quality

- Ultrasonic sealing method means no heat is used

- Rugged PINSONIC ultrasonic components

- Minimal floorspace requirements

Efficient and cost effective

- High speed unit for multiple packers

- Low cost valve sealing

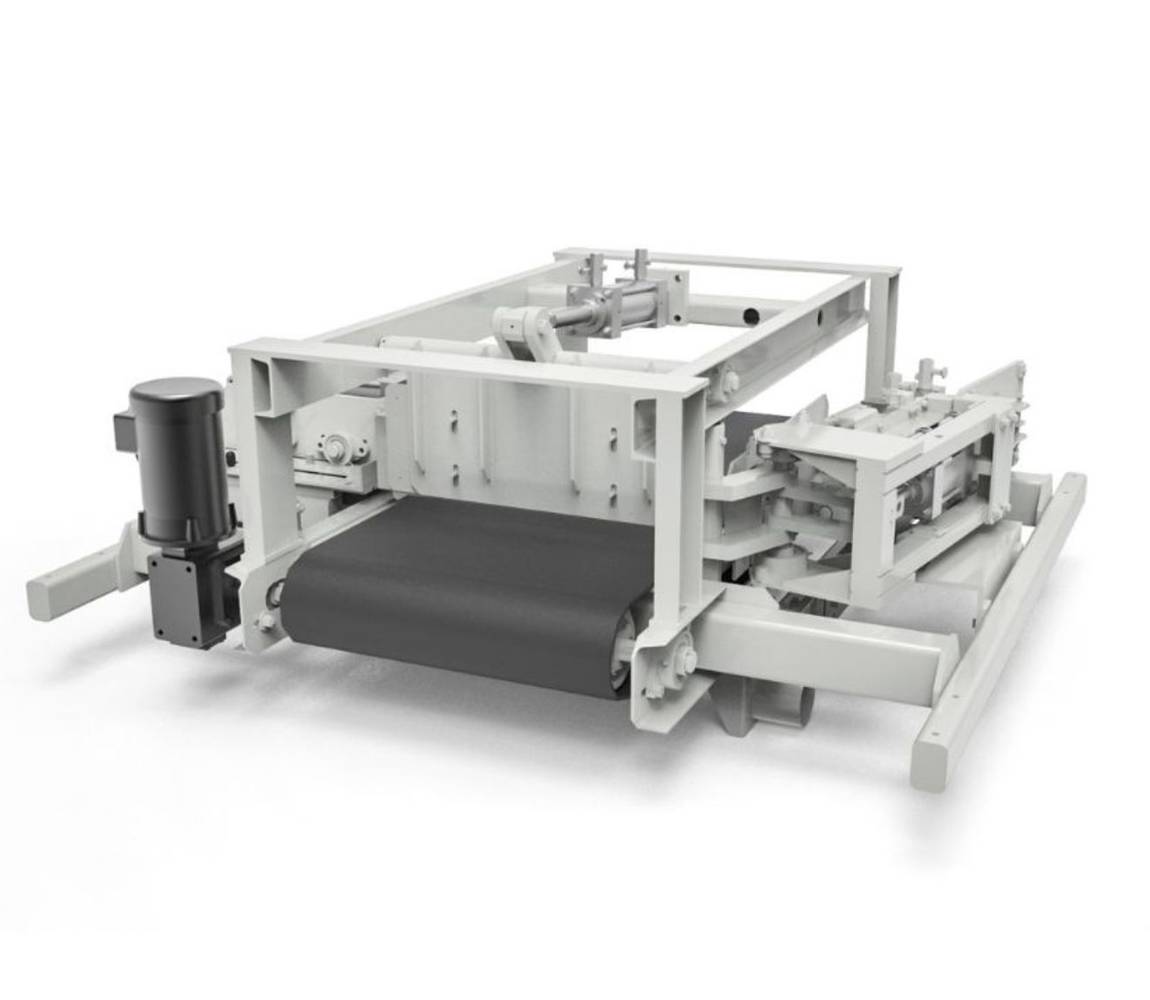

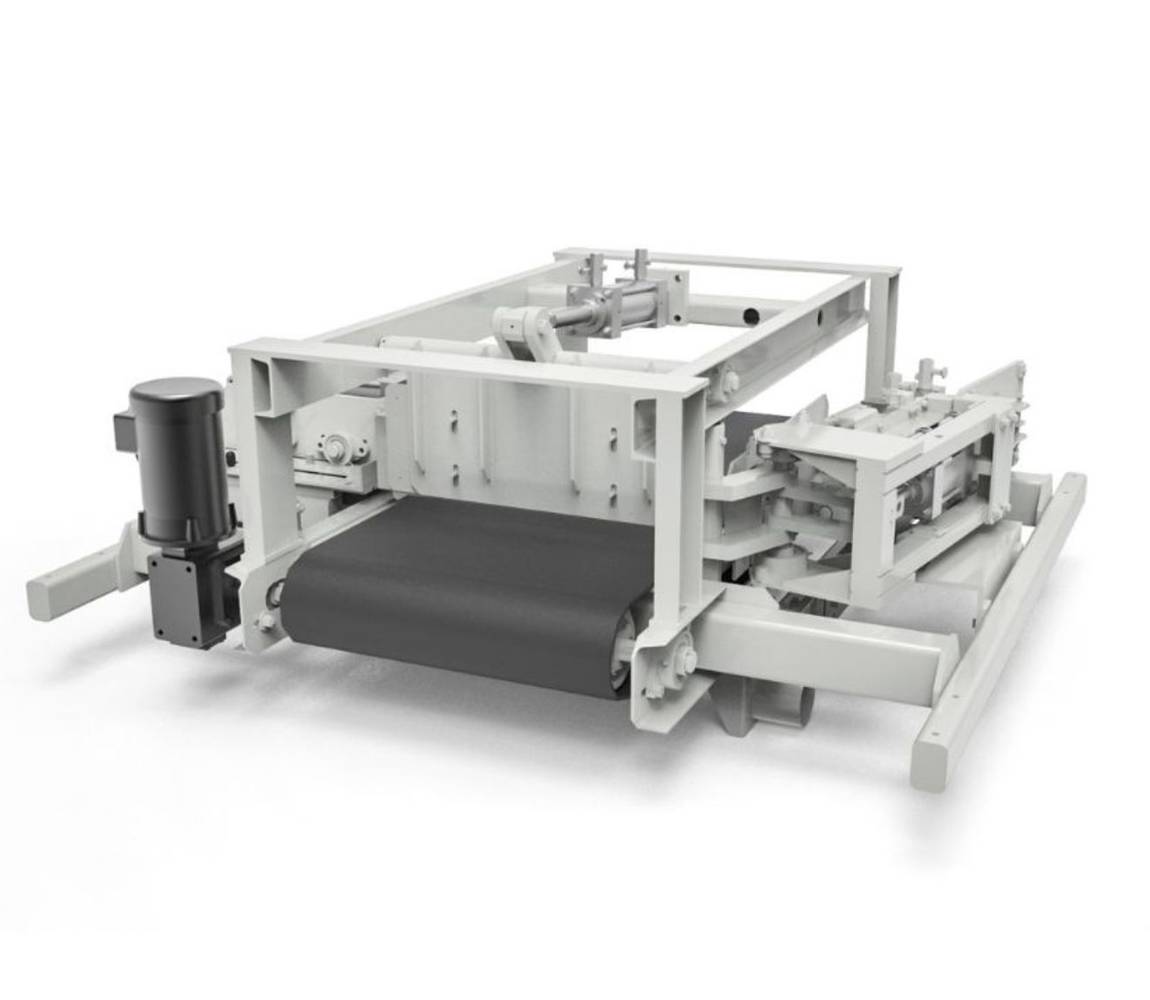

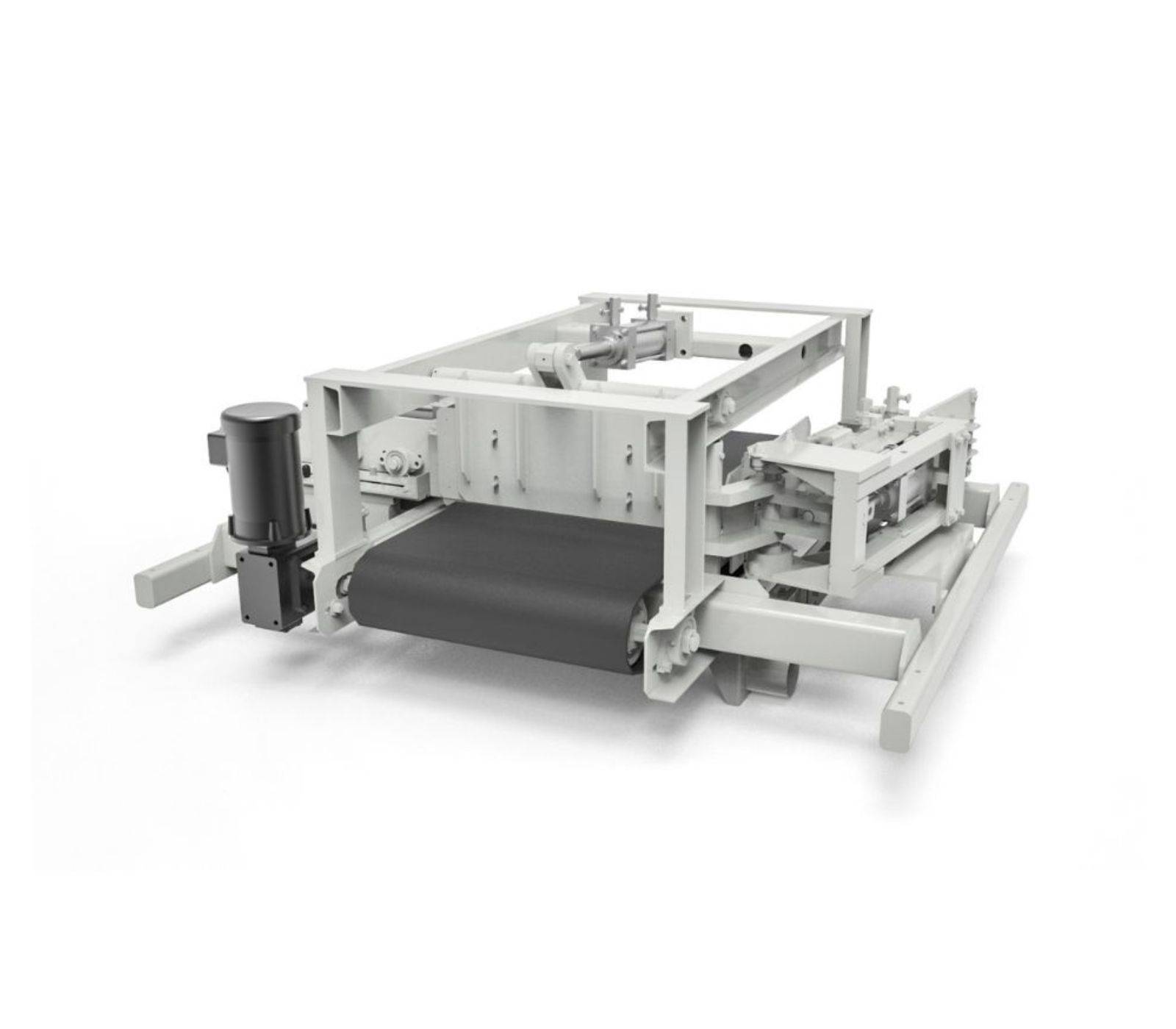

2001 Single-deck inline sealer

- Up to 10 bags per minute

- Single sealer

2001 Single-deck inline sealer

- Up to 10 bags per minute

- Single sealer

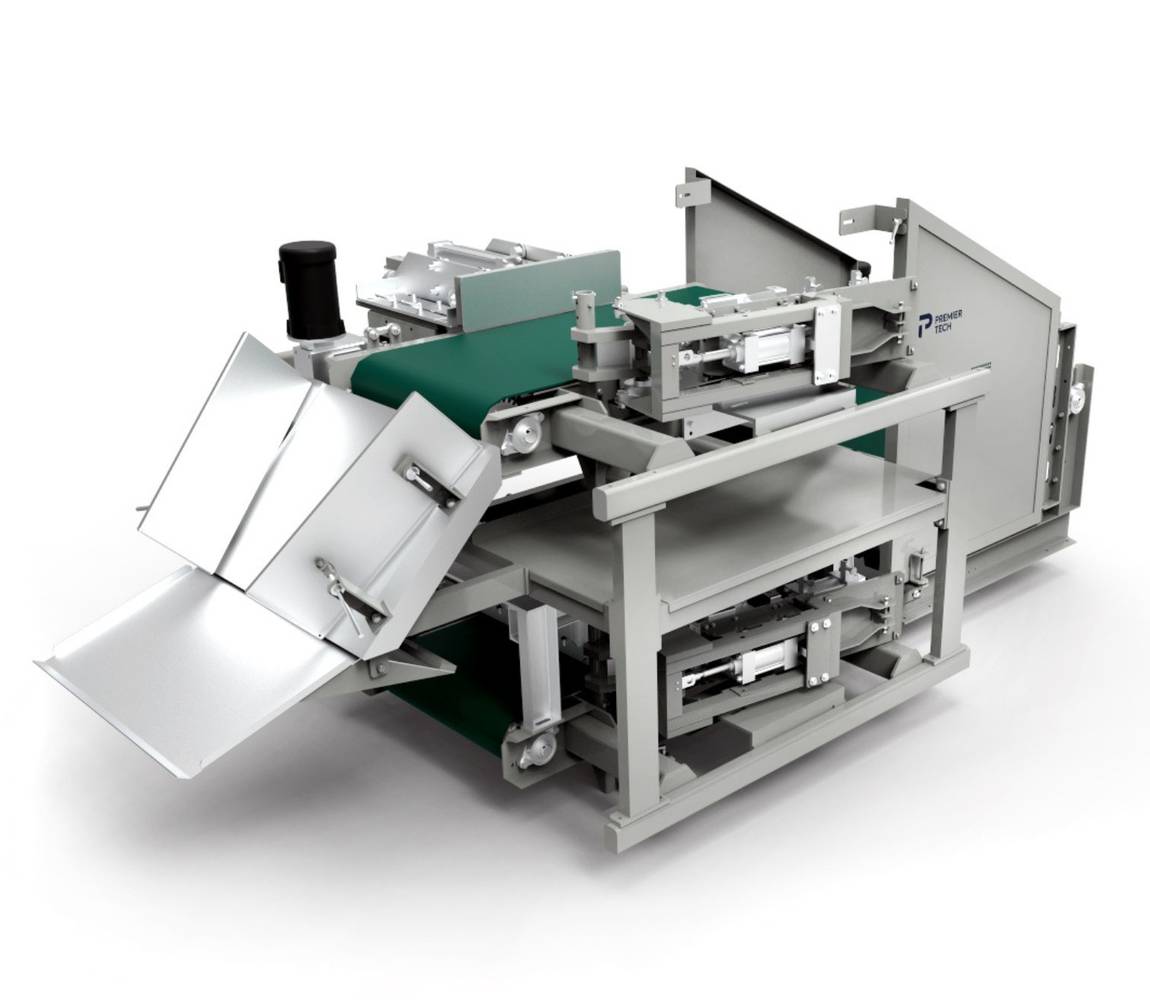

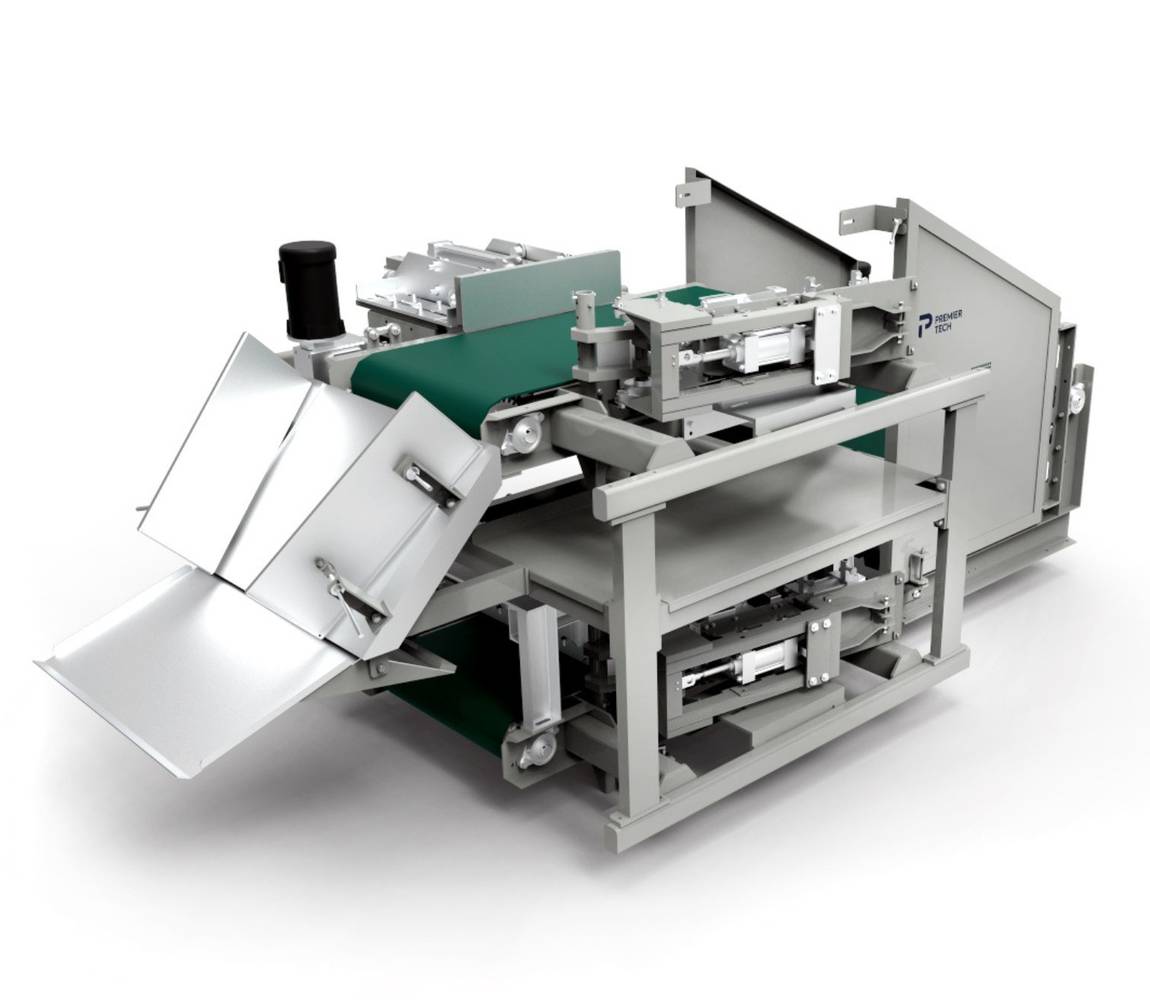

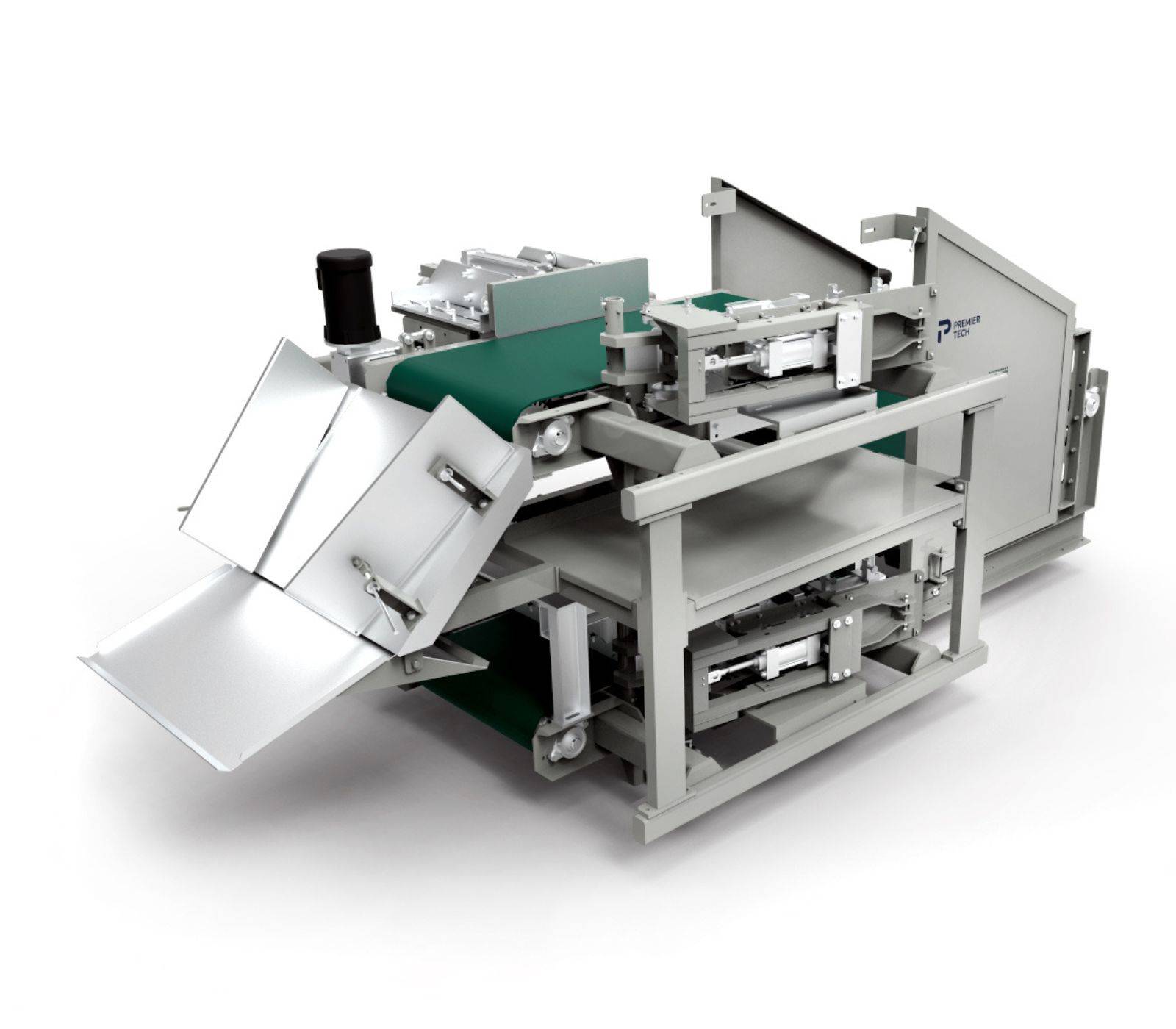

2002 High-speed double-deck inline sealer

- Up to 20 bags per minute

- Two sealers stacked on top of the other

- Equipped with a bag diverter that alternately sends bags to the upper and lower sealer decks

2002 High-speed double-deck inline sealer

- Up to 20 bags per minute

- Two sealers stacked on top of the other

- Equipped with a bag diverter that alternately sends bags to the upper and lower sealer decks

Get pricing and additional information

Need help finding the right bag closing equipment?

Call us

We will be happy to answer

your questions

Sales

Parts & technical support

Request a quote

Tell us about your project, and we will reply with solution recommendations