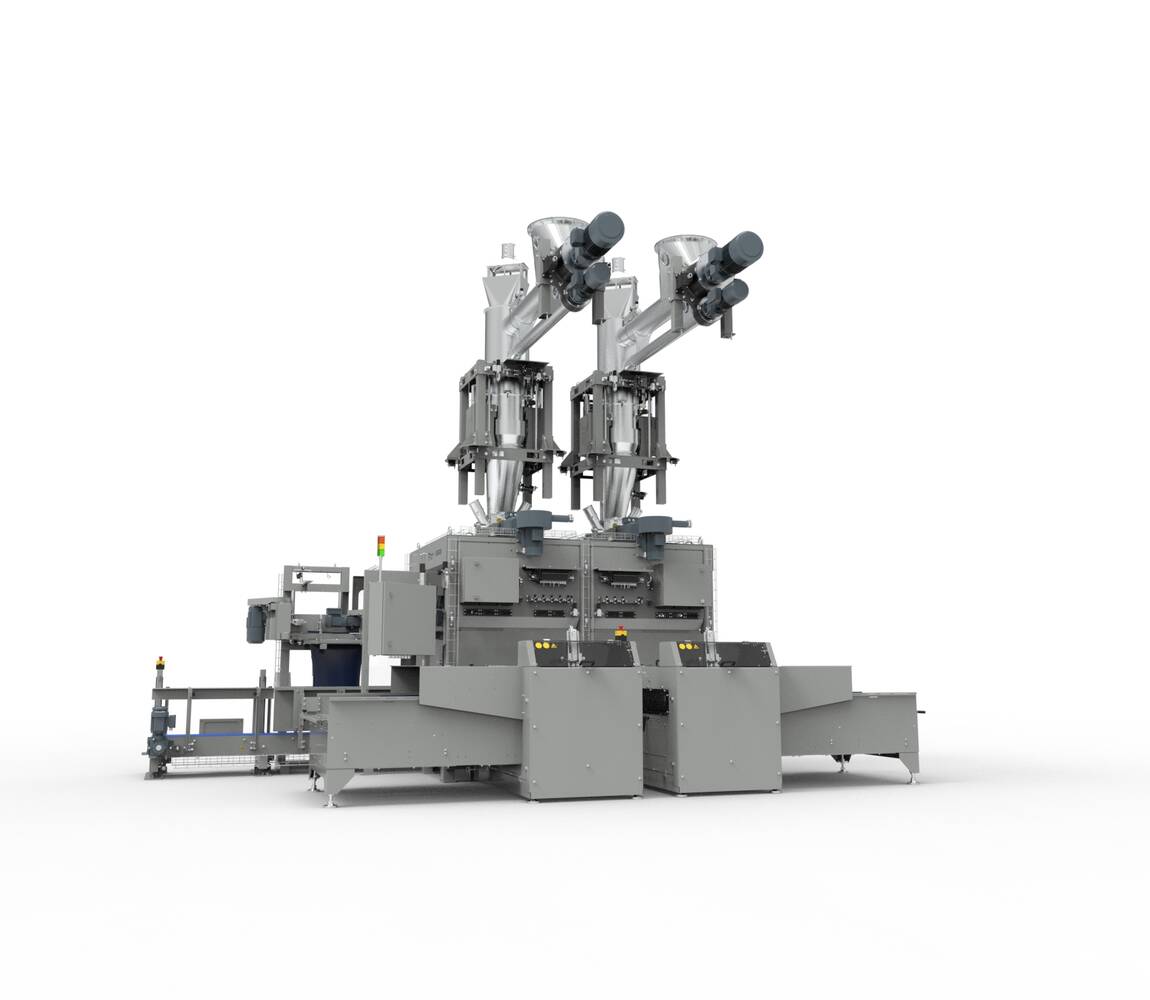

CHRONOS OMP-B SERIESOpen-mouth powder bagging machine

Available in

Africa, Asia, Europe and Latin America*Excluding Brazil and Japan

In partnership with

This high-performance open-mouth bagging system efficiently fills bags ranging from 10 kg to 50kg bags* with powders, making it ideal for wheat and maize flour.

This new flour packaging machine achieves high filling rates while reducing dust emissions. The dosing system, a fusion of Premier Tech and Bühler's expertise, contributes to a clean, reliable and accurate bagging process that maintains product quality and integrity.

Economical and user-friendly, this open-mouth bagging equipment represents our most cost-effective powder bagging machine. It is an excellent choice for upgrading from traditional carousel baggers or automating manual packaging operations.

Speed: up to 15 bags per minute (900 per hour)*

Bulk materials: flour

Bag types: pillow and gusseted

Bag materials: paper and polywoven

Bag weight: from 10 to 50 kg (22 to 110 lb)*

* Depending on the application, bag characteristics, and machine configuration. Each machine is configured for one specific bag size within the 10–50 kg range.

Features

Efficient and reliable

- Can be equipped with up to two twin filling spouts and a net weigher with a double-screw feeder for rapid production

- High accuracy: up to ±50 g at 2 sigma for 25 kg bags

- Robust and ergonomic construction

- Produced at our ISO 9001 certified BTEC site

Clean and safe

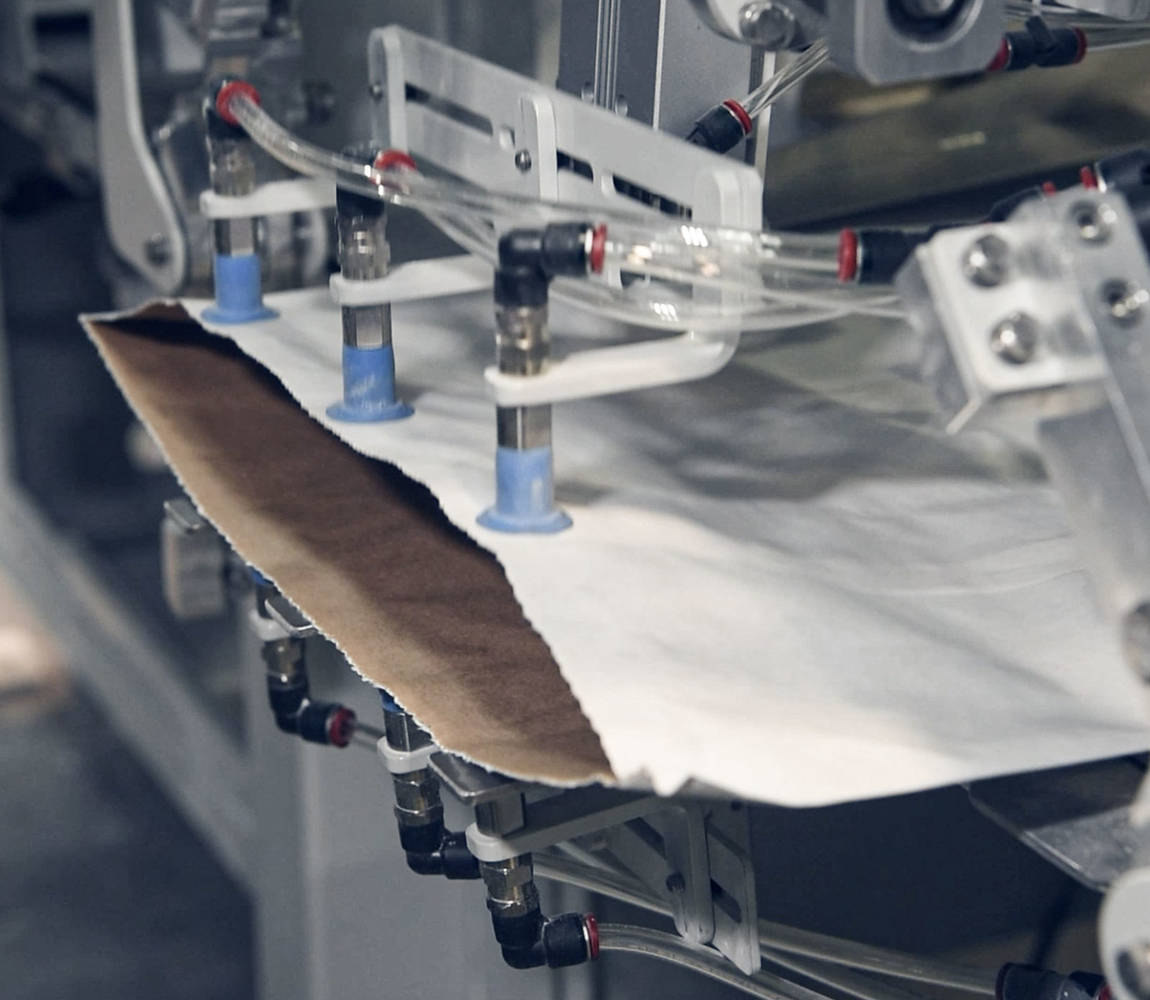

- Detection system prevents spills by ensuring proper bag placement

- Efficient dust collection minimizes energy use, product loss, and dust emissions

- Bag settling evenly distributes powders and removes excess air

- Contact parts are made of stainless steel, food-safe materials or food grade oil motors

Ease of use

- PLC with user-friendly touchscreen for simple operation, troubleshooting, and error codes

- Easy access for cleaning and maintenance

- Multi-stack bag magazines for longer run times and quick reloading

Options

- Automatic opening for partially welded polywoven bags using hot wire cutting

- Air-cooled control cabinet

- Compatible with bag sewing machines

- Bag exit

- Hygienic screw feeder with options for access doors

- Manual or automatic conveyor height adjustment

- Automatic adjustment for full bag size range

- Centralized dust collection port

- Various screw feeder lengths

- Different weigher/scale volumes for bag size optimization

Specifications

Typical footprint 4230 mm L x 6440 mm W x 5240 mm H (166" L x 253" W x 206" H)*

Bag dimensions Width: 320 to 700 mm (12" to 27")*

Length: 600 to 1100 mm (23" to 43")*

Weight: 10 to 50 kg (22 to 110 lb)*

Bag closing systems Plain sew (single or double stitch), plain sew with a single fold

Electrical requirements 3 × 400 V (± 10%) @ 50 Hz or 3 × 440 V @ 60 Hz

Ambient temperature 40 °F to 122°F / 5 °C to 50 °C

* Depending on the model, please download the brochure for additional details

CHRONOS OMP-2090 B

- Up to 15 bags per minute (900 per hour)

- Equipped with 2 screw feeders

- Bag magazine capacity: Up to 480 bags

CHRONOS OMP-2090 B

- Up to 15 bags per minute (900 per hour)

- Equipped with 2 screw feeders

- Bag magazine capacity: Up to 480 bags

CHRONOS OMP-1045 B

- Up to 7 bags per minute (450 per hour)

- Equipped with 1 screw feeder

- Bag magazine capacity: Up to 480 bags (alternative: up to 400 bags)

CHRONOS OMP-1045 B

- Up to 7 bags per minute (450 per hour)

- Equipped with 1 screw feeder

- Bag magazine capacity: Up to 480 bags (alternative: up to 400 bags)

Get pricing and additional information

Need help finding the right open-mouth bagger?

Request a quote

Tell us about your project, and we will reply with solution recommendations