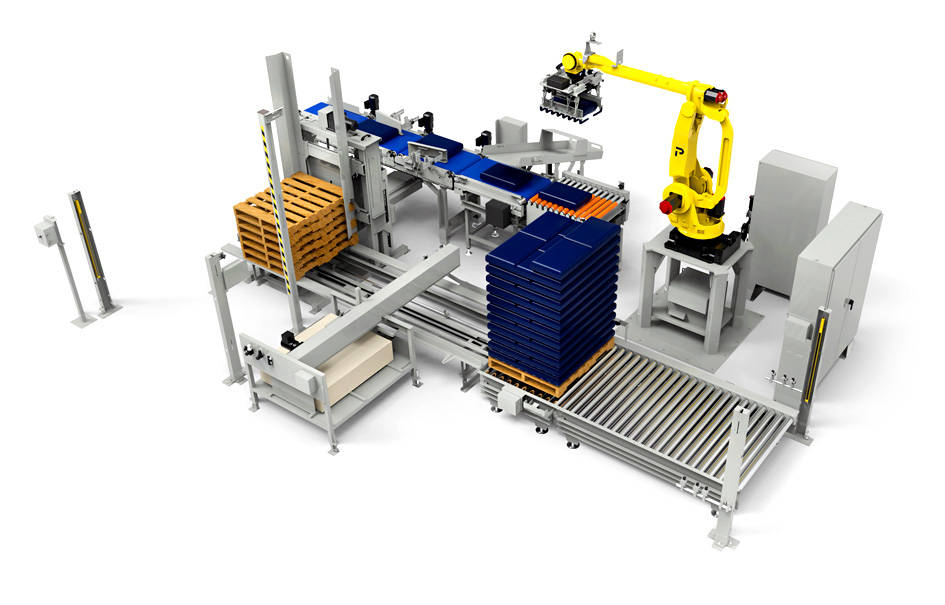

CHRONOS RPL-4000 SERIESHigh-performant palletizing robot

Available in

Canada & USA and Latin AmericaThe RPL-4000 Series provides the highest production rates of our offerings. It is ideal for new factory buildings or warehouses facing volume increases.

The equipment's design allows the robot to focus solely on stacking incoming products. Other tasks, such as dispensing the pallets and the sheets, are handled automatically by independent equipment.

Full loads exit without the robot's intervention, enabling continuous palletizing operations and increased throughputs.

Speed for cases: from 20 to 80* per minute (1200 to 4800* per hour)

Speed for bags: up to 23 per minute (1380 per hour)

Applications: bags, bales, bundles, cases, trays, and totes

*With multi-unit picks

Features

Increased capabilities

- Automatic pallet dispenser that can house different pallet sizes

- Complete load removal without the robot’s intervention, reducing downtime considerably

- Durable and low-maintenance components

Versatile robot

- Carefully designed and robust end effector to ensure proper handling and protection of your product

- For bags, standard models have a soft and malleable finger gripper to prevent bag damage, dropping issues, and tears

- FANUC robot used for its steady performance, speed, and flexibility

Enhanced safety and palletizing control

- High safety fences with interlocked access doors

- Light curtains

- Safety management software to lower the risk of equipment damage

- Intuitive HMI with 3D visualization for easy operation, pattern creation, fault detection, and troubleshooting

Options

- Finger, clamp, or vacuum end effector

- Powered slip or top sheet dispenser for maximum speed

- Stainless steel components to meet sanitary requirements and facilitate cleaning

- Integration with third-party printers, labelers, pallet, and product traceability, and more

- Multiple infeed conveyor configurations to meet your desired production rate

- Stand-alone operating station which can be located anywhere along your production line

- Integration with pallet wrapping and conveying equipment

Additional options for bags

- Rejection conveyor for non-compliant bags

- Automatic bag width adjustment

- Weight check system

RPL-4111

- Up to 23 units per minute (1380 per hour)

- Picks a single unit from 1 production line

- Places it on 1 stacking station on the motorized conveyor

RPL-4111

- Up to 23 units per minute (1380 per hour)

- Picks a single unit from 1 production line

- Places it on 1 stacking station on the motorized conveyor

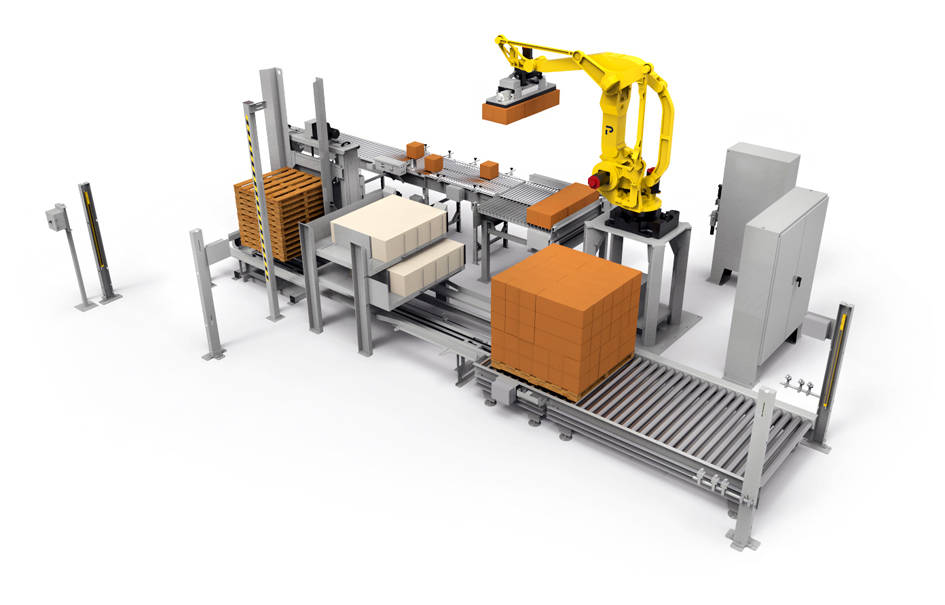

RPL-4311*

- From 30 to 80 cases per minute (1800 to 4800 per hour)

- Picks multiple units from 1 production line simultaneously

- Places them on 1 stacking station on the motorized conveyor

- Includes a preparation conveyor where the units are gathered

- Achieves higher production rates

*For cases only

RPL-4311*

- From 30 to 80 cases per minute (1800 to 4800 per hour)

- Picks multiple units from 1 production line simultaneously

- Places them on 1 stacking station on the motorized conveyor

- Includes a preparation conveyor where the units are gathered

- Achieves higher production rates

*For cases only

Get pricing and additional information

“Safety on this equipment is absolutely top-notch. The security fencing and the doors, the light curtains that keep people from crossing into dangerous zones. It’s very good”

Dallas Stevenson

Maintenance for Packaging Operations, Grain Millers

Need help finding the right palletizer?

Request a quote

Tell us about your project, and we will reply with solution recommendations