Precision Under Pressure: Case Packing for a Bottling Giant

When rapid growth meets fragile products, the result isn’t always elegant—unless you have the right partner.

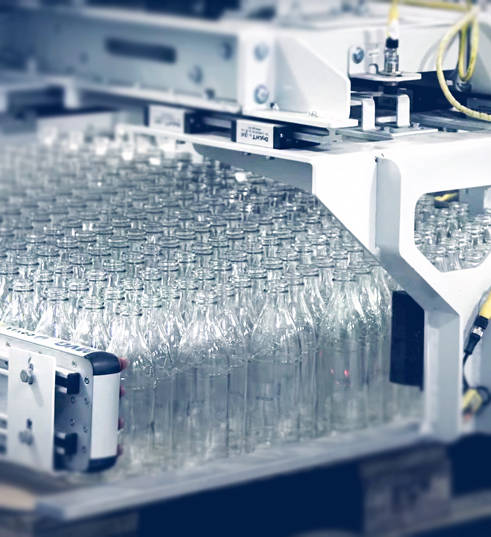

That was the situation faced by a leading North American bottling company as their product demand soared. Scaling up meant reevaluating their entire end-of-line packaging process. But the catch? Their products were extremely delicate, requiring both speed and a soft touch.

That’s where the Premier Tech team came in, turning a complex challenge into a story of smart automation, seamless integration, and customer-first support.

The growth that sparked transformation

As the company experienced a surge in demand, it quickly became clear that their existing setup wouldn’t keep up.

“We've experienced the growth of the sales that has resulted in us needing to expand outside the facility for distribution, converting all our bottles and starting to look for new equipment,” — Heyward Garner, Chief Operating Officer

Their bottling line needed more than a basic upgrade—it needed a full automation solution that could handle depalletizing, fragile case packing, and robotic palletizing in a single integrated system.

And most importantly, the centerpiece of it all—the case packing—had to be engineered with absolute care.

Fragility meets innovation: The case packing challenge

Packing fragile bottles at high speeds is a tall order. Any jolt or misalignment can lead to product loss, not to mention costly downtime. Premier Tech approached the challenge with a solution built around the CHRONOS CPC Series Modular Robotic Case Packer, tailored to preserve the integrity of each bottle while maintaining high throughput.

Highlights of the solution

- 3D printed end-of-arm tooling: Custom-designed to the shape and fragility of the bottles, these soft-grip tools reduced breakage risk and optimized product handling.

- Vision-guided robotics: Compact FANUC robots equipped with vision systems ensured every item was placed with precision, adapting on the fly to changes on the line.

- User-friendly interface: Rather than complex programming, the system was designed for intuitive use—even by operators without a tech background.

“With Premier Tech we were able to change patterns, there's no need to have a laptop programming degree or anything—it’s just, you know, almost simple enough for my momma to do it.” — Eddie Martin, Controls Engineer Automation Specialist

Support that stands out

Great automation is more than equipment—it’s about service that shows up when it matters. For the client, that’s where the Premier Tech team truly stood apart.

“The biggest help for me from Premier Tech has been the technical support. As soon as you get someone on the line they're very patient, they are very helpful, and the follow-up is incredible—because normally you don't get that from a company.” — Eddie Martin, Controls Engineer Automation Specialist

The result: Growth without compromise

By working closely with the client’s team, Premier Tech delivered a system that combined speed, accuracy, and delicacy. Bottles were packed efficiently and safely, pallets were built robotically, and operations scaled without the headaches of manual intervention or damaged goods.

And perhaps most importantly—the new system gave the company the confidence to keep growing.

This project reflects a broader trend we’re seeing across industries: companies needing to scale up without expanding their physical footprint. Systems such as these help multiple clients double their production capacity without additional space, using smart automation and modular design to maximize efficiency within existing facilities.

When custom matters

At Premier Tech, we believe automation should adapt to your product—not the other way around. This project is a perfect example of how smart design, customer collaboration, and world-class support can turn a fragile challenge into a flexible, future-proof solution.

To see the full story come to life, watch the video testimonial and discover what’s possible when innovation meets partnership.