CHRONOS HVS-180 SERIESInsulation bagging machine

Available in

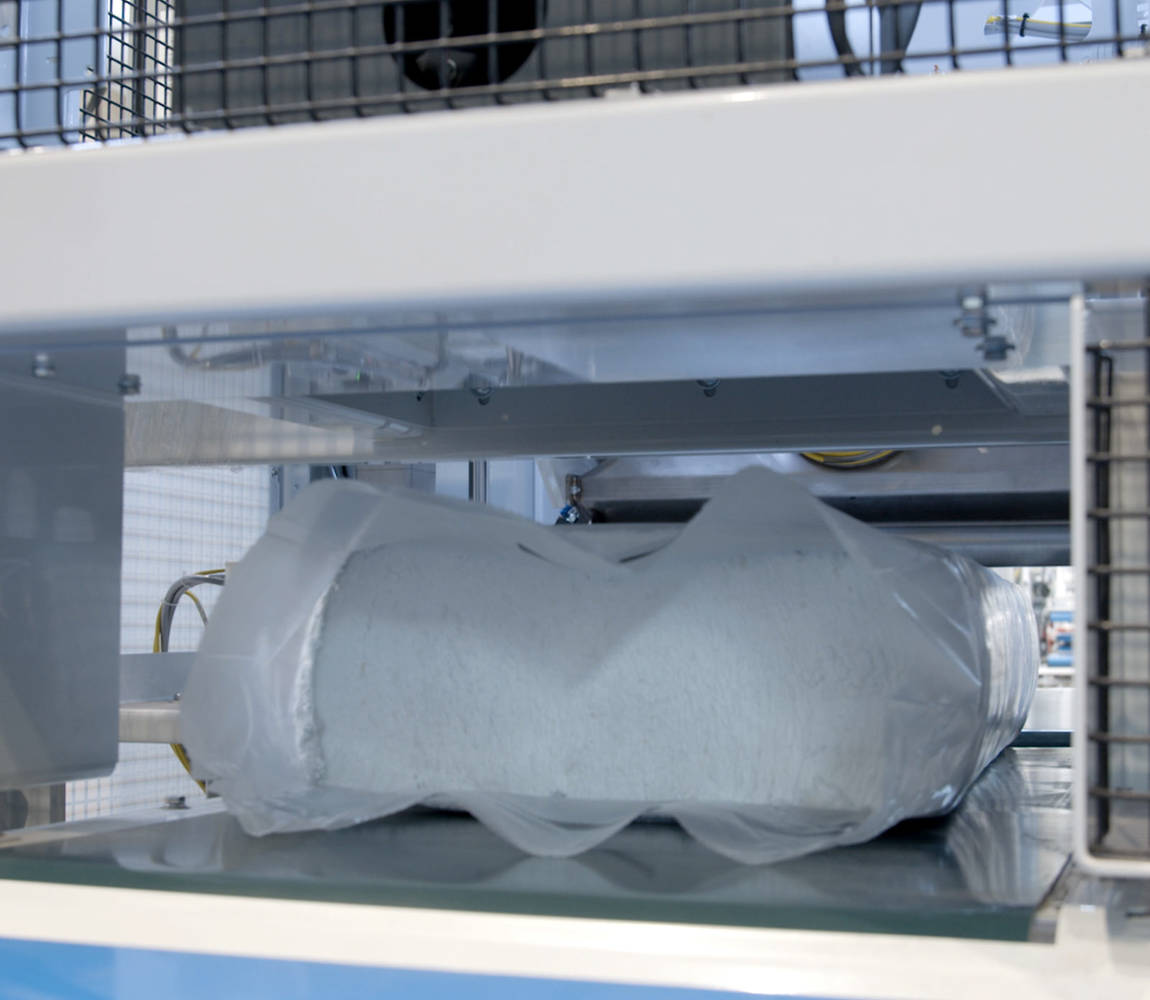

Africa, Asia, Canada & USA, Europe, Latin America and OceaniaThe HVS-180 Series insulation bagging machine is a semi or fully automatic system intended to package compressible bulk products such as natural or synthetic fibers (fiberglass insulation, ceramic fiber, wood fiber, etc.).

It is designed to perform densification in the gusset direction, producing medium-size bales with a flat face which are easier to palletize. Since this insulation bagger uses a two-stage densification system, the ratio can be up to 30:1 depending on the application requirements and product characteristics.

Speed: up to 3 bales per minute

Bulk materials: fibers

Bag types: bales and gusseted flat-bottom bales

Bag materials: polyethylene and wicketed bags

Features

Rugged construction

- Designed for harsh environments

- Built with high-quality components that meet the highest standards of heavy industries

- Heavy-duty hydraulic cylinders for the three major movements, and pneumatic cylinders for other mechanisms

Cost efficient

- Equipped with densification chamber fed by a load cell-mounted weigh hopper for excellent weighing accuracy

- Densification ratio up to 30:1, therefore reducing shipping and packaging material costs

Options

- Bag clamp

- Fully automated system when adding the HAT Series Bag Placing and Sealing Modules

- Centralized dust collection ports

- Highly wear-resistant surfaces

- High-speed version

Specifications

Typical footprint: 144” (3658 mm) L x 231” (5882 mm) W x 348” to 378” (8839 to 9601 mm) H

Densification rate: 30: 1*

Accuracy: ± 1/2 lb (227 g) @ 2 sigma*

Operating system: PLC

Dust collecting requirements: 6000 scfm (169 901 L/min)

Air consumption: Up to 26 scfm @ 100 psi (736 L/min @ 7 bars)

Electrical requirements: 460 V / 3 Ph / 60 Hz (other voltages available)

* Depending on product characteristics, method of feeding, and bag size, and thickness

Get pricing and additional information

Need help finding the right compression bagger?

Request a quote

Tell us about your project, and we will reply with solution recommendations