Client Services

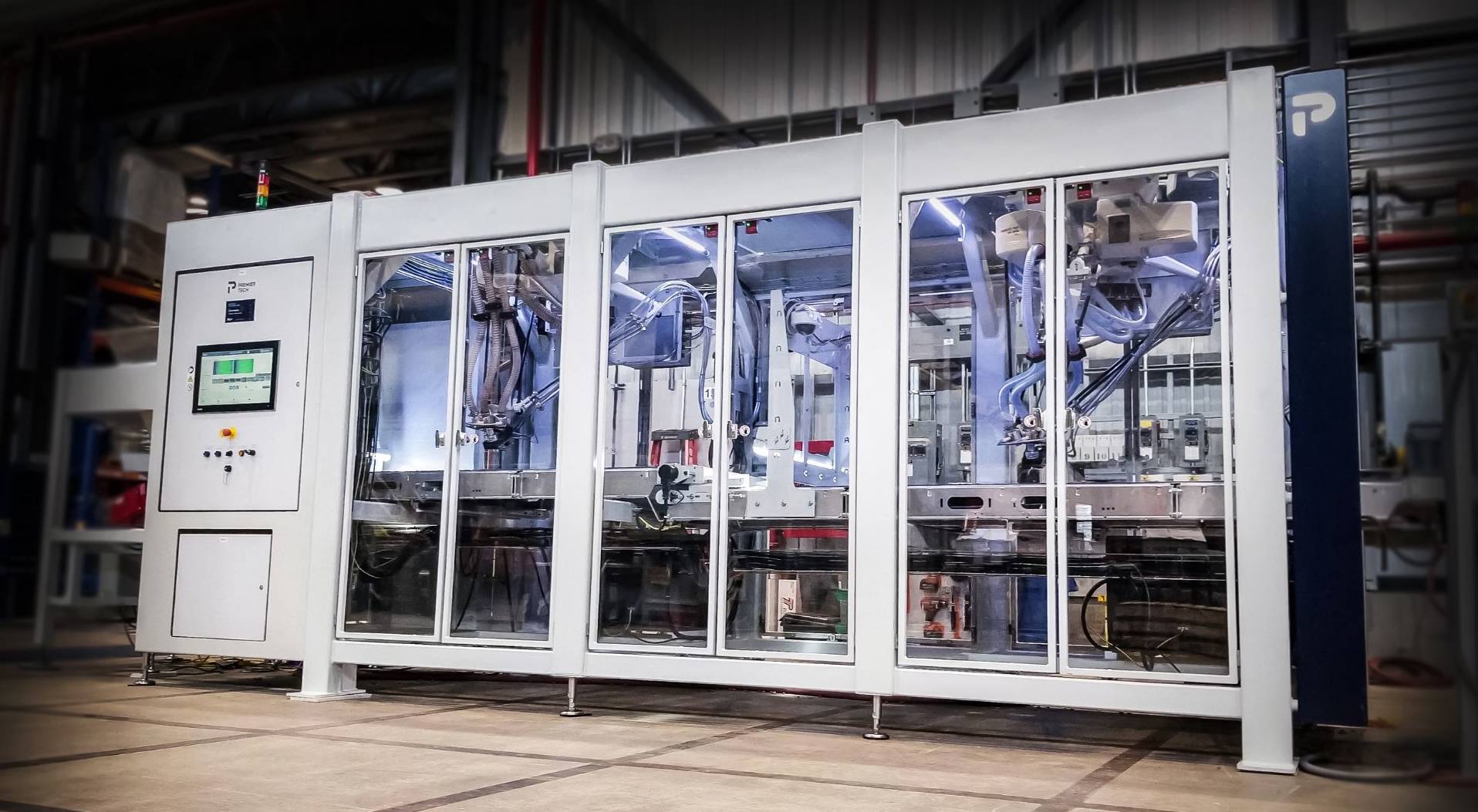

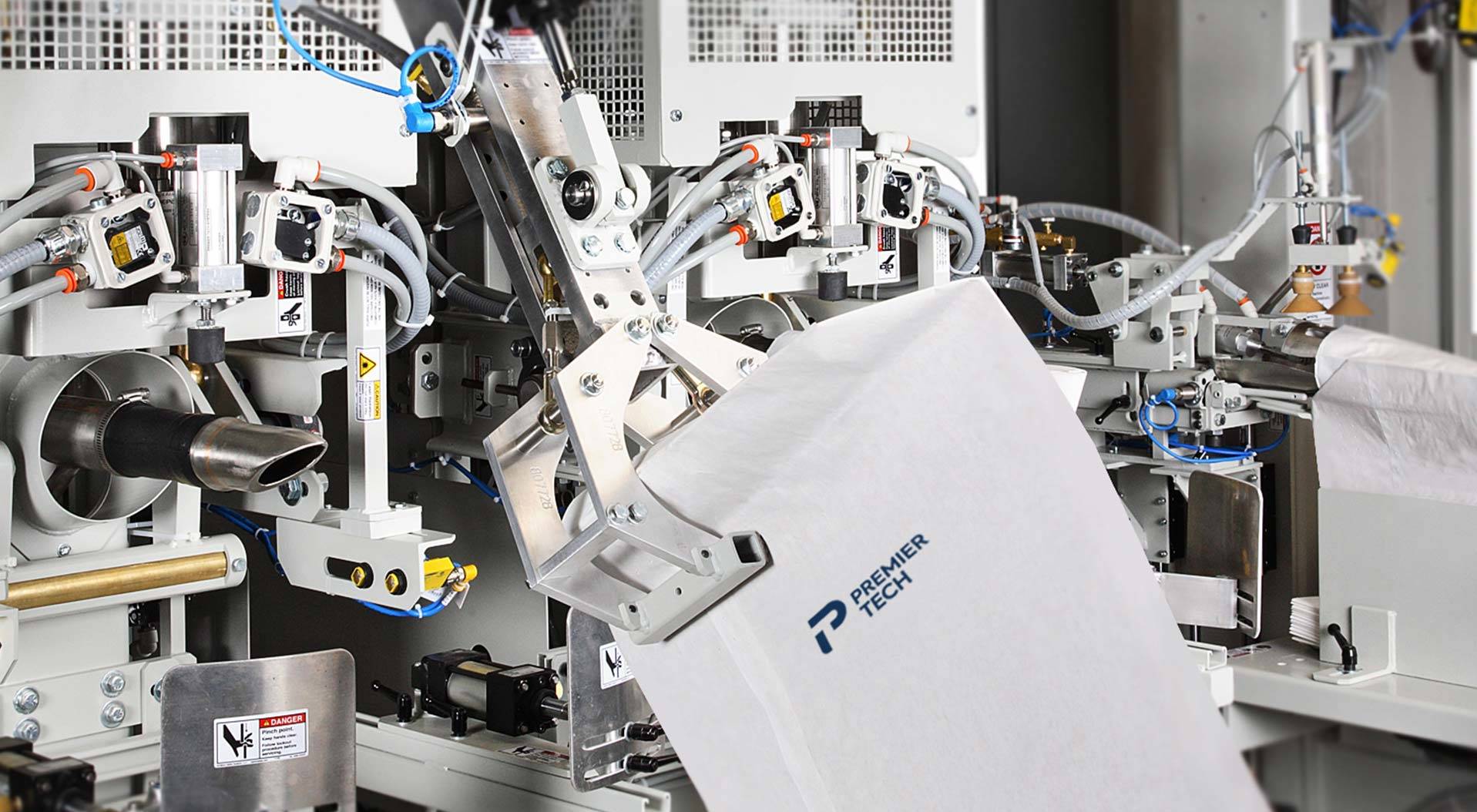

Premier Tech's plug-and-play operator training program efficiently onboards new hires, ensuring safety. It includes printable cheat sheets, and interactive content, all accessible online, to help operators quickly become proficient and reduce turnover impacts.

Read more