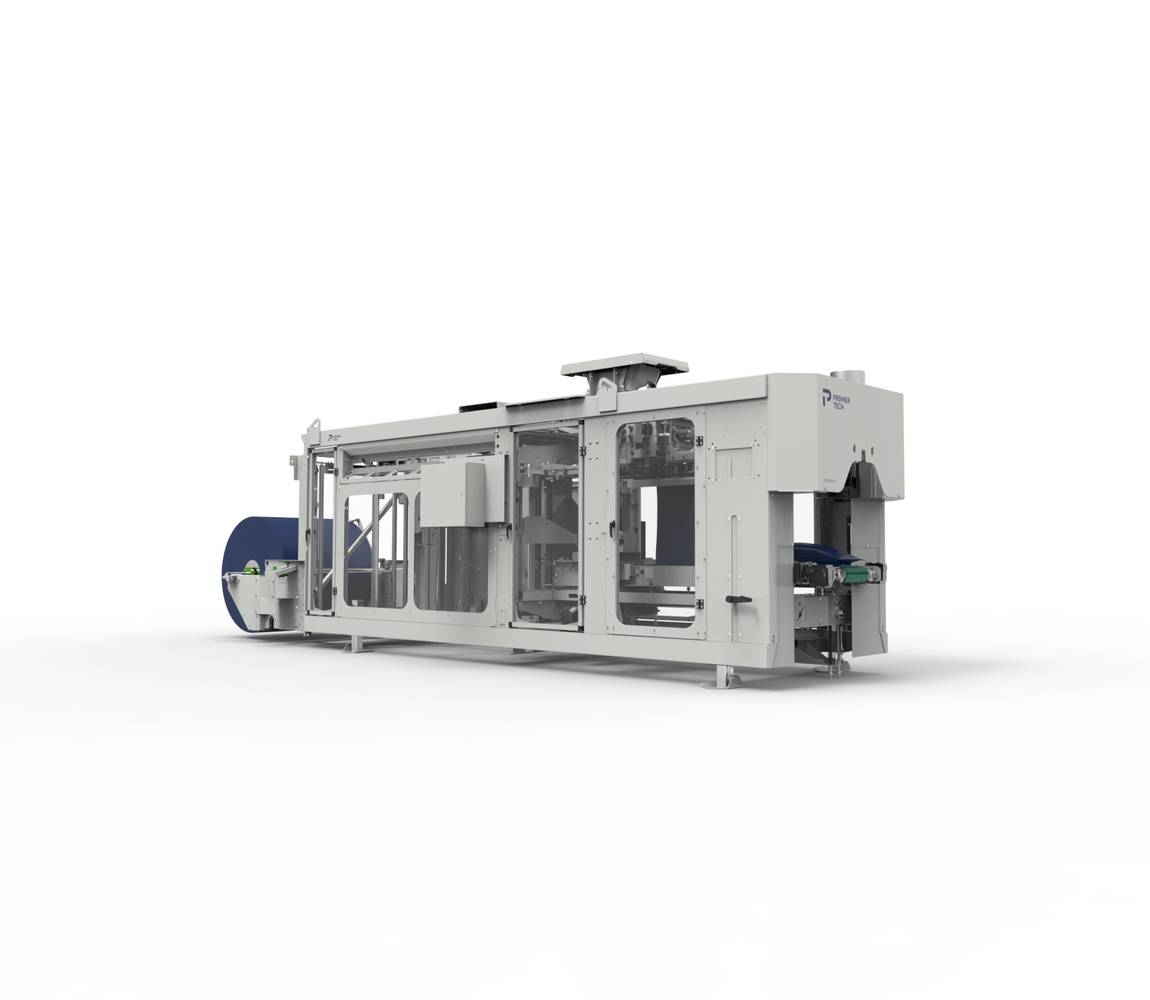

CHRONOS FSH SERIESHorizontal form fill seal machine

Available in

Canada & USA and Latin AmericaThe FSH Series horizontal form-fill-seal machine is a fully automatic bagger that creates bags from pre-printed plastic film. It efficiently packages loose-fill materials, including organic and landscaping products like soil, mulch, compost, and sand.

FFS bagging machines offer outstanding performance, unrivaled reliability, and significant reductions in packaging material costs. They are ideal for automating the packaging process and seamlessly integrating with mixing lines and palletizers.

With more than 350 form fill and seal machines sold worldwide, Premier Tech is a leader in the industry.

Speed: up to 35 bags per minute (2000 per hour)

Bulk materials: fibers, flakes, granules, pellets

Bag types: center-folded film

Bag materials: PE

Bag weight: 4.5 to 100 quarts (5 to 110 L)

Features

Versatile

- Packages a wide range of loose-fill materials in bags of various sizes

- Provides the widest range of bag options

- Many film roll support configurations to fit layouts constraints

Safe and reliable

- Ergonomic design providing good visibility and allowing easy adjustments and maintenance operations inside the guarded area

- Robust industrial construction ensures durability and long lifespan

- Automatic detection system for overfilled and non-filled bags

User-friendly

- Intuitive HMI enables operators to optimize production rates by quickly identifying equipment slowdown factors

- Only one control panel for all electrical components

Options

- Complete infeed system

- Weighing scales and volumetric feeders

- Size adjustable filling chute for quick bag size changeovers

- Pneumatic film roll support for efficient roll handling

- Integrated bottom gusset former and corner sealer

- Settling device for best top seal integrity

- Bag top trimmer for clean looking bags

- Perforated holes to facilitate air removal before palletizing

- Conveyor height adjustment system

Available retrofits

Explore our extensive list of retrofits designed for your FSH machine (previously FFS Series) to enhance its capabilities.

Get pricing and additional information

Need help finding the right form fill and seal bagger?

Call us

We will be happy to answer

your questions

Sales

Parts & technical support

Request a quote

Tell us about your project, and we will reply with solution recommendations