Retrofits for FFS Series

Retrofits bring many important upgrades to your form fill and seal bagger. Discover the retrofits that can increase uptime, provide a better user-experience and that include powerful features such as faster processors.

Side sealer replacement unit

Increase uptime of your equipment

The new side sealer replacement modules simplify the installation and replacement of your side sealer, minimizing equipment downtime.

Retrofit main benefits

- Increased uptime

- Easy installation

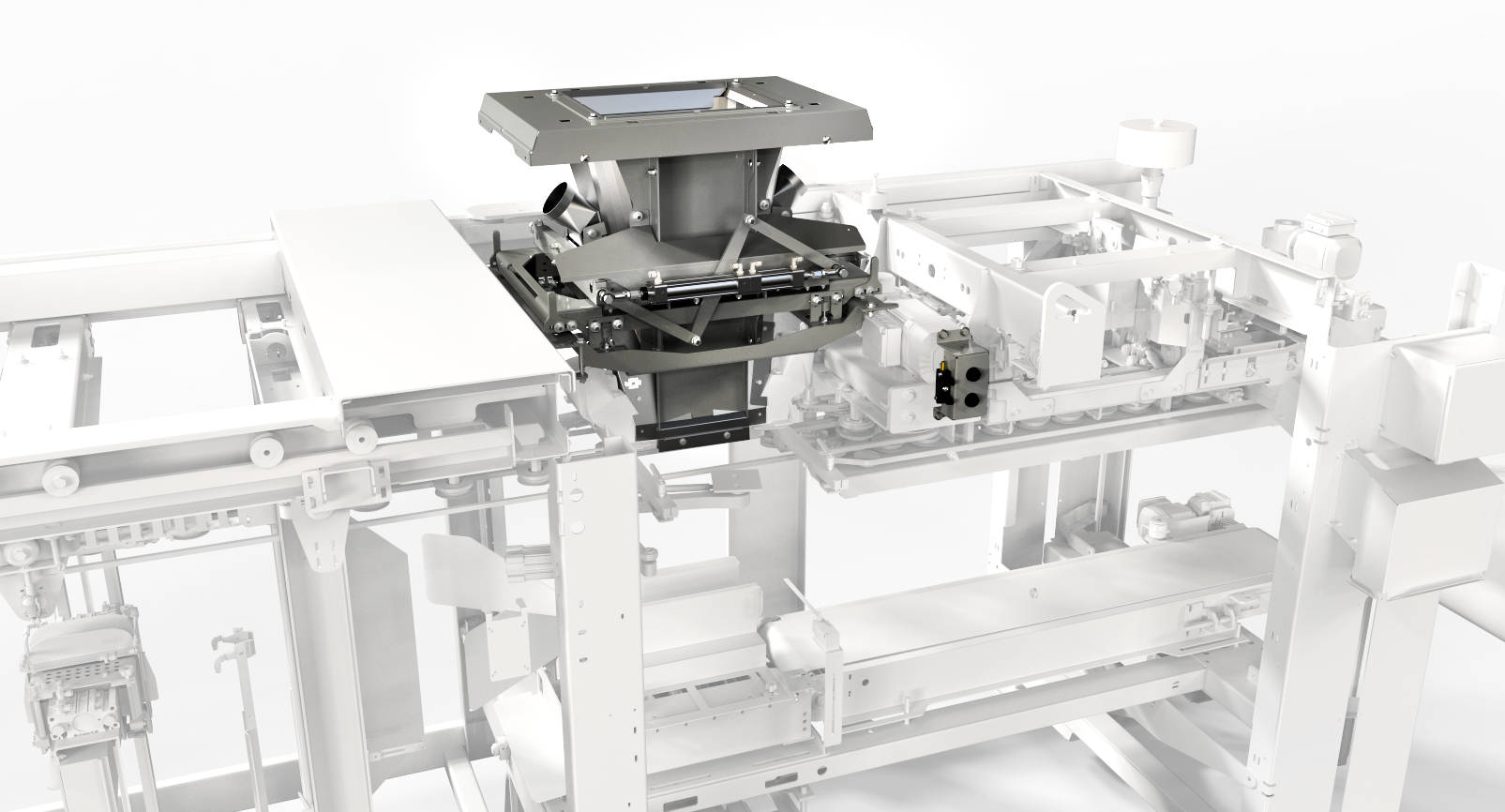

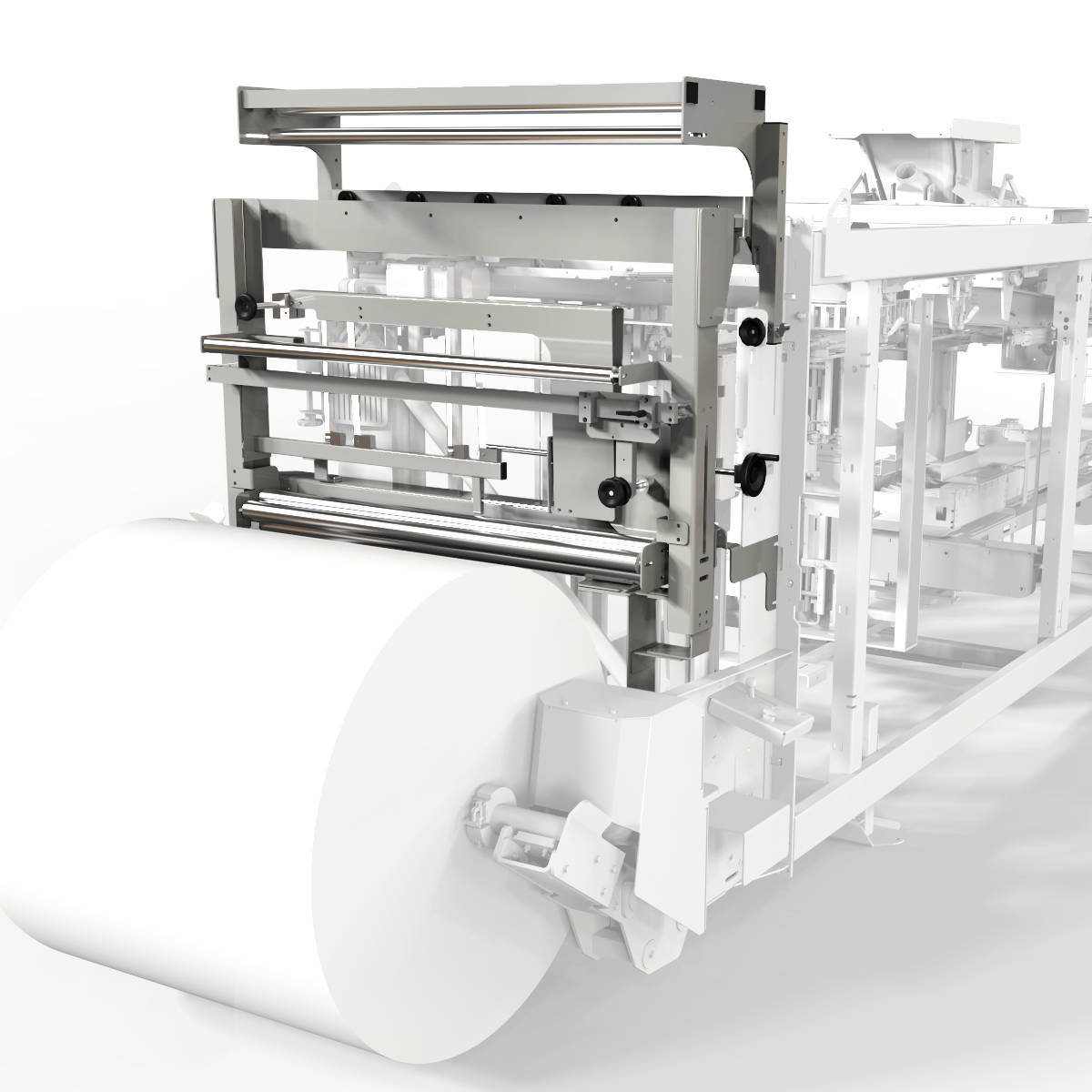

Adjustable filling chute

Increase productivity of your bagging equipment

The single auto adjustable filling chute replaces up to three filling chutes, for any bag sizes from 16 to 24 inches (empty bag width dimensions). The auto adjustment simplifies and significantly reduces bag size changeover time.

Retrofit main benefits

- Increased productivity

- Rapid changeover

- Increased employee safety

HMI upgrade

Enhance your packaging equipment

The new PV-700 panel view is more powerful than its predecessor and has an expanded memory. Please note that the PV-550 and PV-600 have been phased out by Allen Bradley and could cause unwanted downtime if either of them fails.

Retrofit main benefits

- Expanded memory

- Faster processor

- Language compatibility

- Intuitive interface

- Fully touchscreen

Bag top trimmer

Improve your bagging operations

The new bag top trimmer incorporates a highly effective blowing system that constantly ejects excess trim, eliminating the risk of interruption and unnecessary downtime. It is also better located at the exit of the top sealer.

Retrofit main benefits

- Better design

- Improved bag appearance

- Less downtime

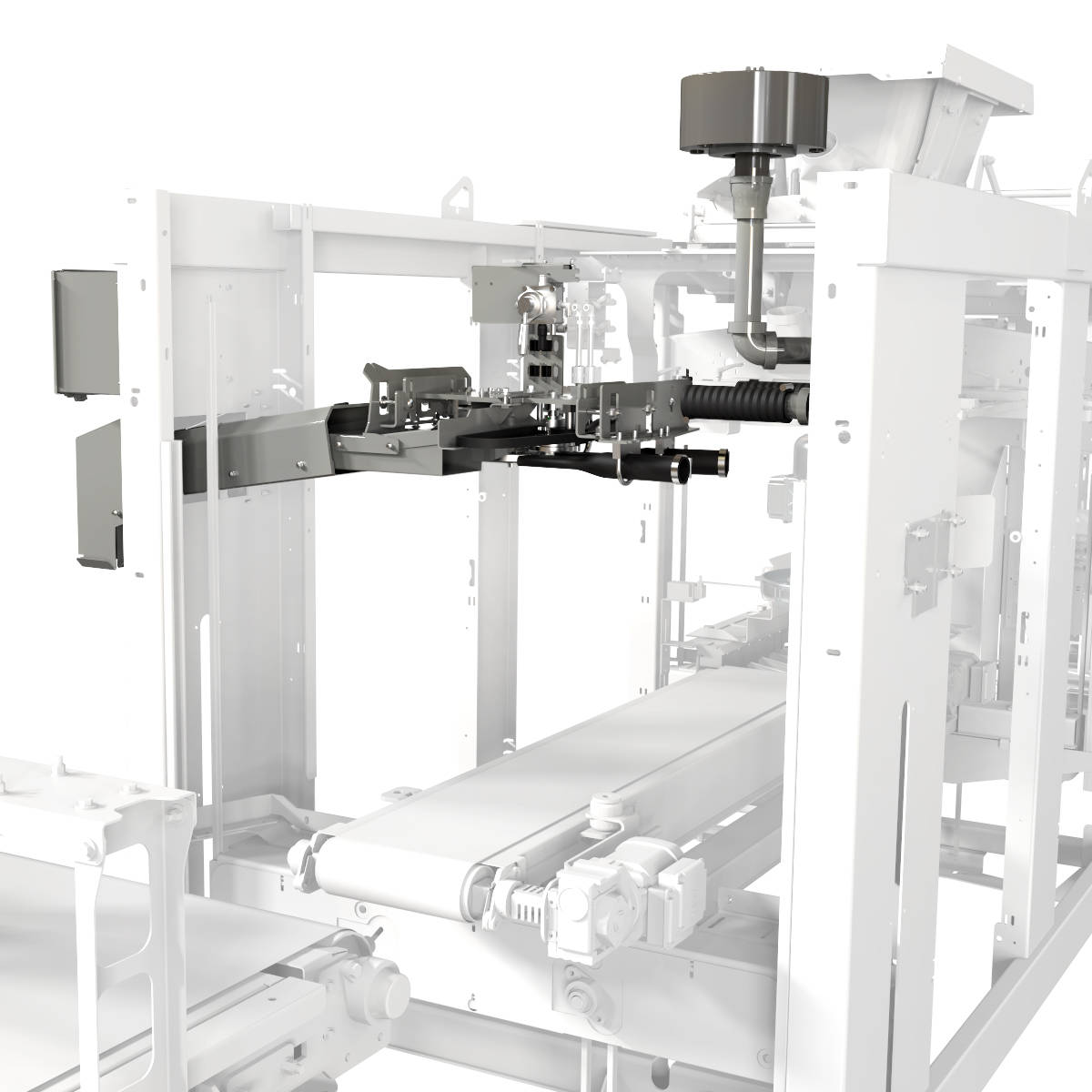

Hole perforator assembly replacement

Upgrade for smoother operation

The replacement hole perforator adds holes to the bag before the filling station so that air can exit the bag as it passes through the flattener.

Retrofit main benefits

- Better design

- Smoother operation

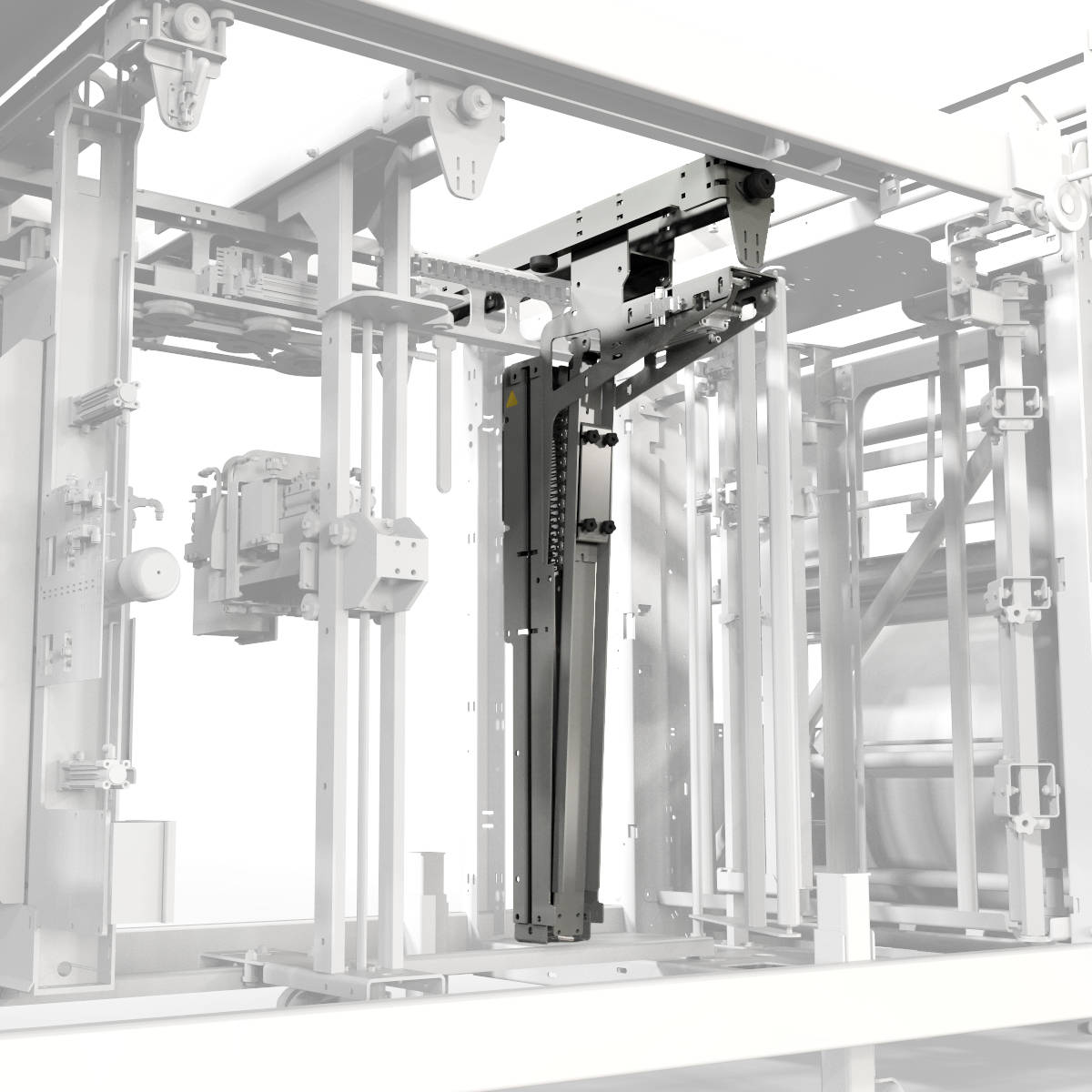

Outfeed conveyor height adjustment system #62

Upgrade for faster and simpler bag changeover

This retrofit allows the operator to adjust the conveying system height directly through the HMI, and also reduces bag changeover time, which means greater output overall.

Retrofit main benefits

- Increased automation

- Faster bag changeover

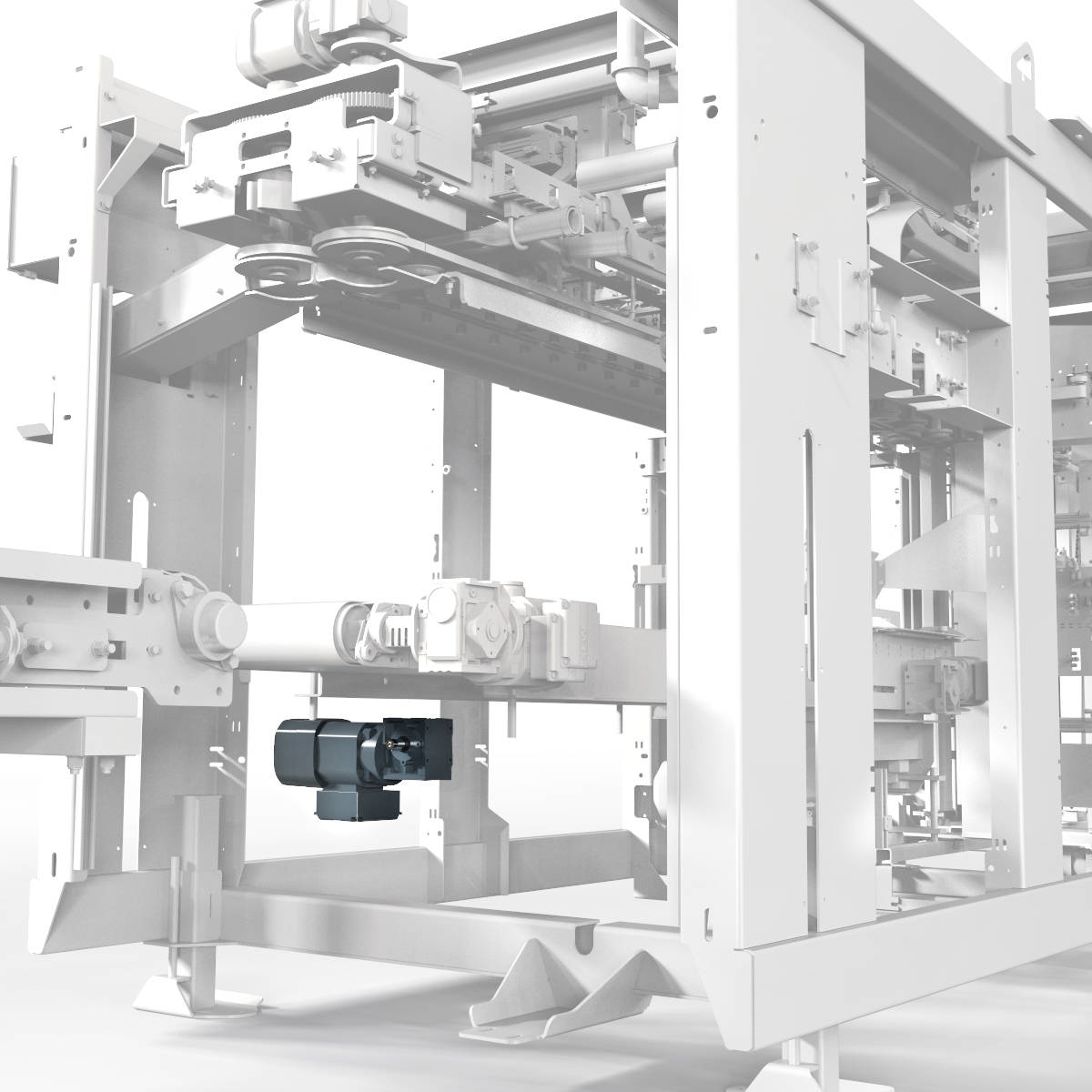

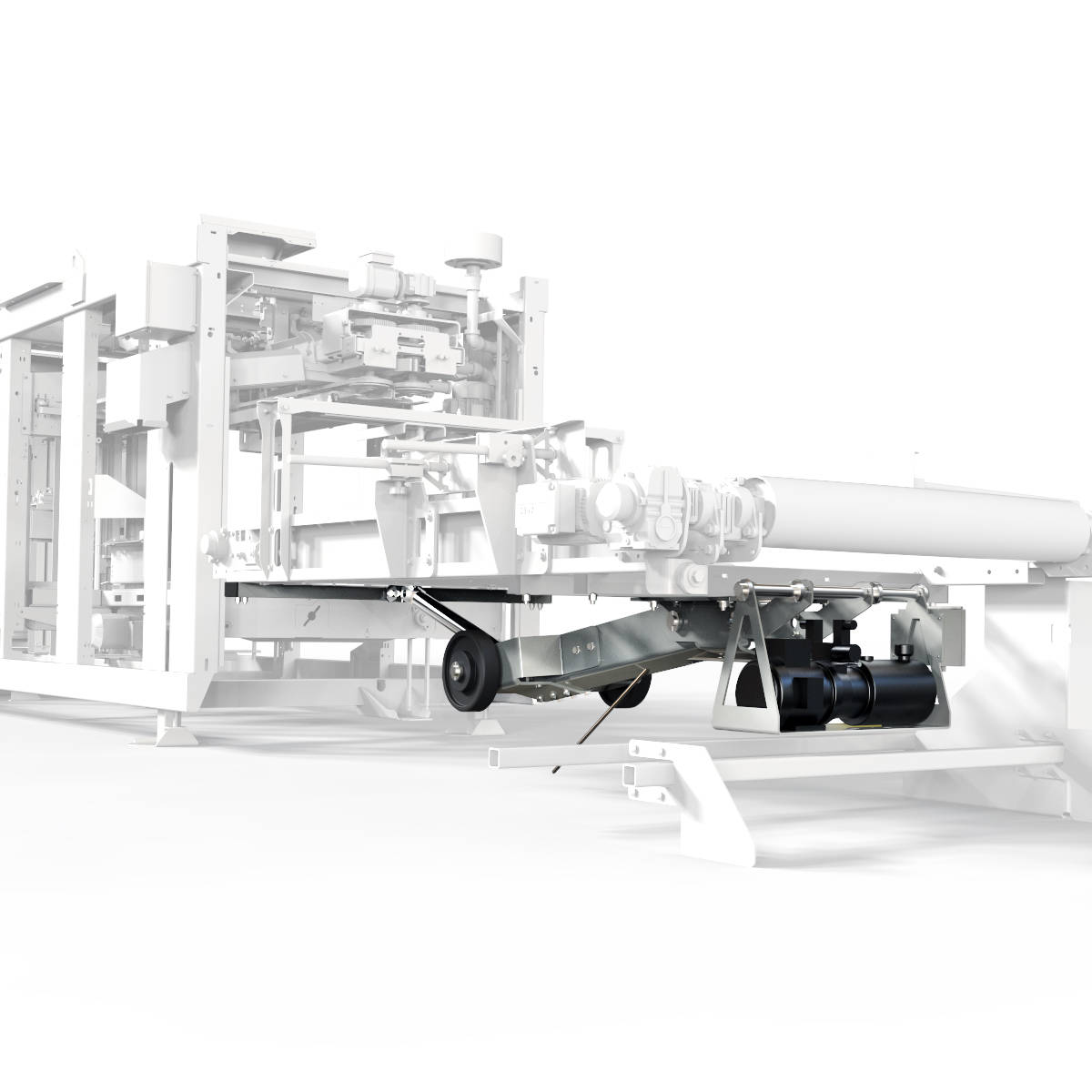

Outfeed conveyor height adjustment system #80

Upgrade for faster and simpler bag changeover

This upgrade replaces the manual lever with a hydraulic system that is controlled via remote. The assembly can be bolted directly onto the conveyor. It only requires 120V and includes low maintenance components.

Retrofit main benefits

- Faster bag changeover

- Quick and easy installation

- Low maintenance

Gusset former

Increase sturdiness and volume of your bags

This device creates a bottom gusset in the bags by using a flat wheel that pushes the folded side of the U-film between two parallel arms to the desired depth. It also comes with a variable frequency drive (VFD) that permits constant film unrolling as well as a brake system that regulates film tension.

Retrofit main benefits

- Increased bag volume

- Smoother operation

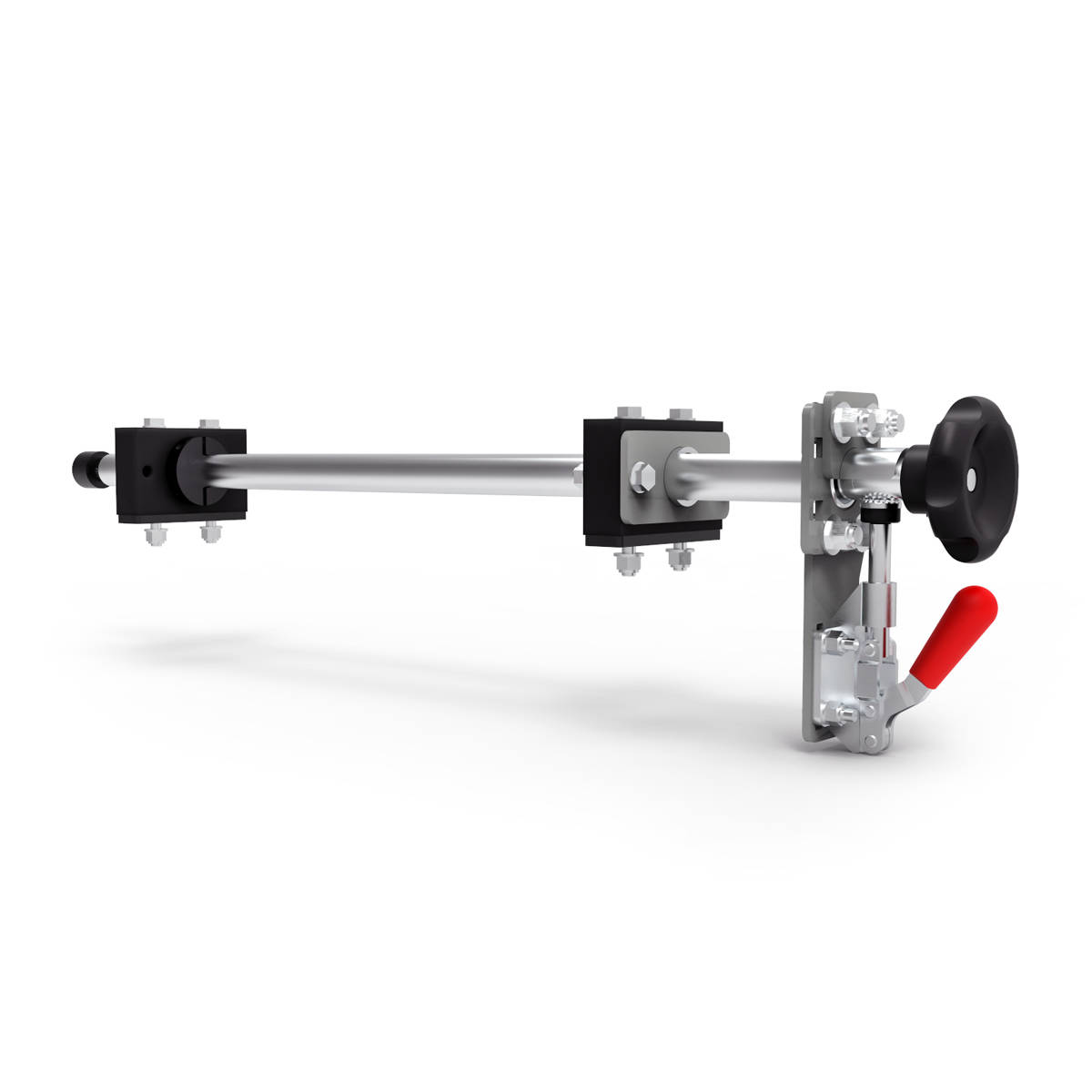

Locking handle system

Improve your machine’s stability

This retrofit is for the side sealer and hole perforator modules. The locking handle system retrofit kit makes handle adjustment easier and prevents friction as the driving shaft is running, reducing bag changeover time by 25% and decreasing the risk of failed bags.

Retrofit main benefits

- Simpler bag changeover

- Increased safety

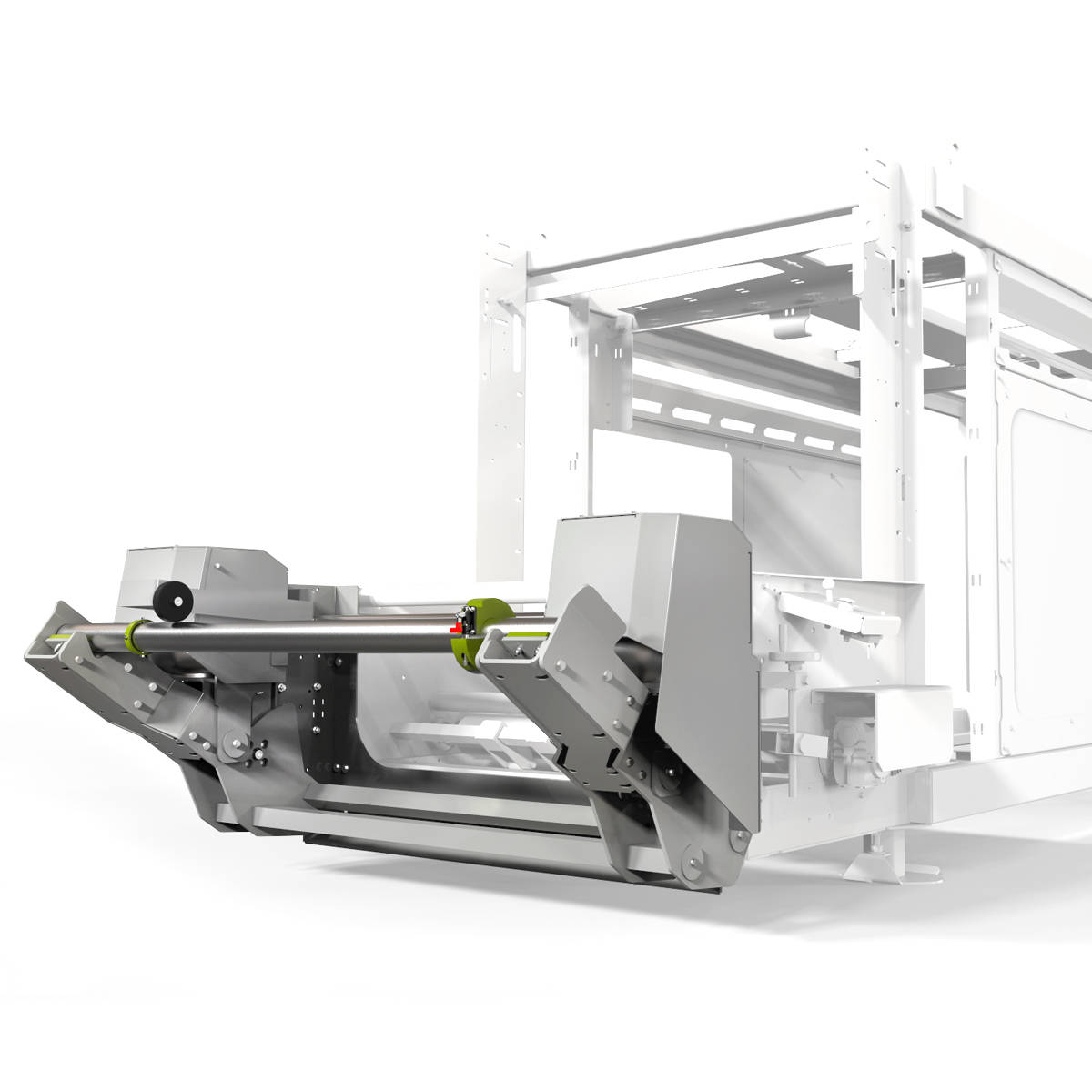

Pneumatic film roll support

Achieve quick and safe film roll changeovers

Instead of a fixed roll support, the new pneumatic film roll moves to allow for quicker and easier roll handling, easing the film roll replacement procedure. This retrofit also raises the heavy film roll from the floor, eliminating the need for human manipulation.

Retrofit main benefits

- Increased safety

- Reduced changeover time

- Greater self-sufficiency

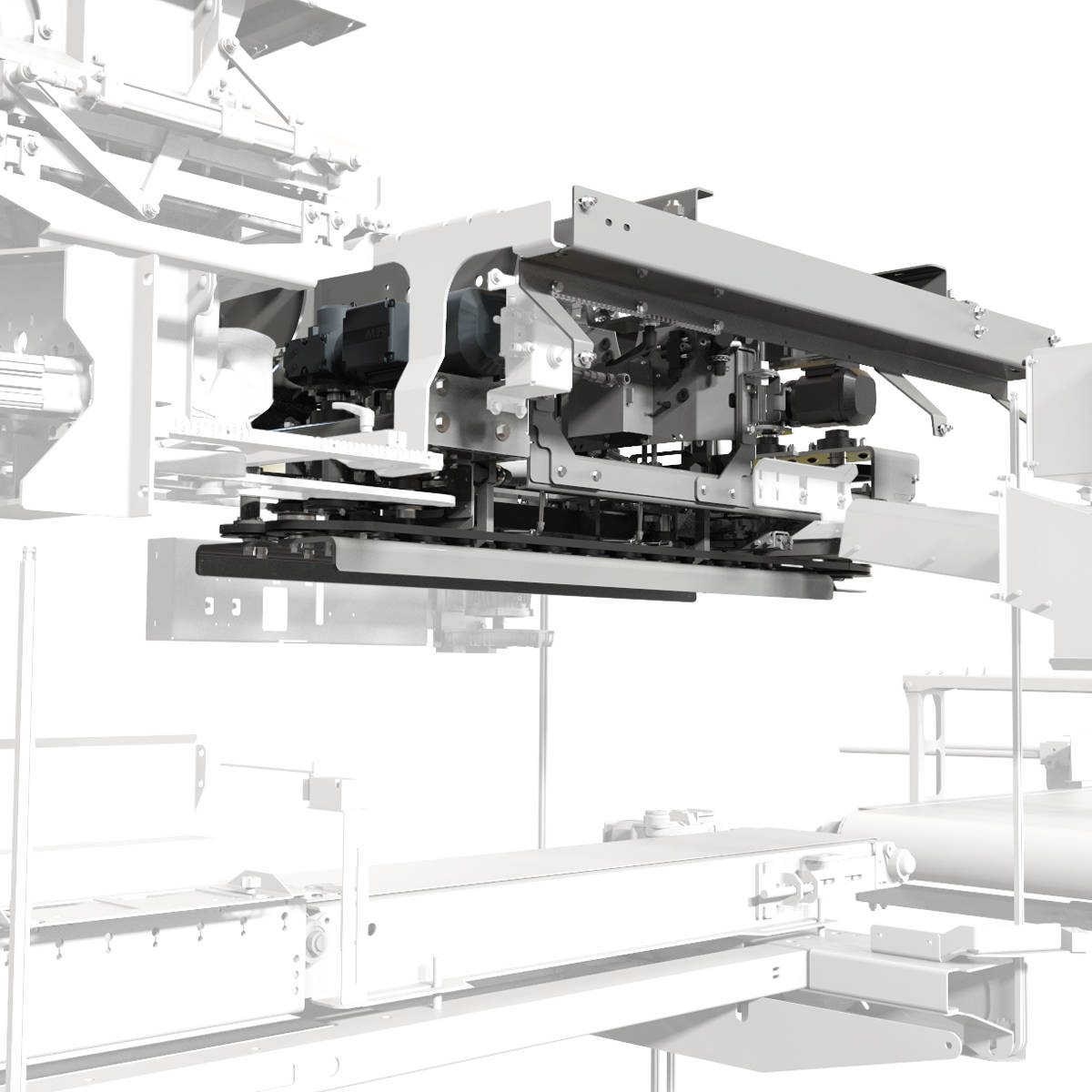

Top sealer retrofit

Increase seal integrity and increase uptime

This new pneumatic top sealer system provides a safe way to keep the heating modules hot for reduced downtime and increases sealing quality. The new design also integrates a standard overfilled bags detection system and has a 30% lifetime increase on rotating parts compared to the previous model.

Retrofit main benefits

- Easy access to internal components

- More uptime

- Better sealing quality

VFD drive upgrade

Increase your bagger’s uptime

The VFD drive has been updated from the Siemens drives to Allen Bradley. The new VFD parameters optimize the equipment’s movements, providing the best version of your bagger. The VFD drive includes the film unwinder and top sealer.

Retrofit main benefits

- Minimized downtime

- Optimized equipment

- Updated drives

Can't find what you're looking for?

We would love to hear from you! If you have any questions or want to know more about our Client Solutions Team, click on the button to reach us.