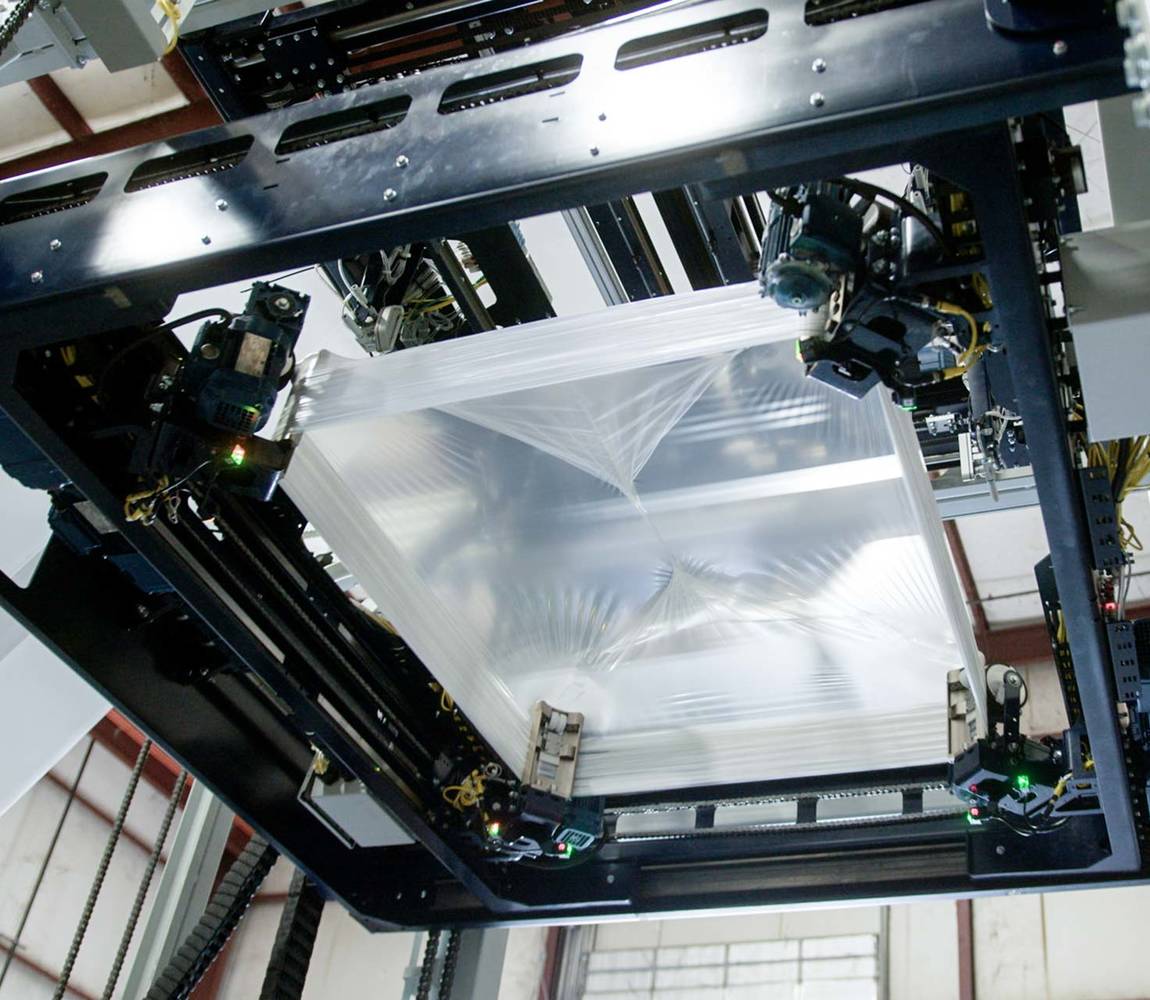

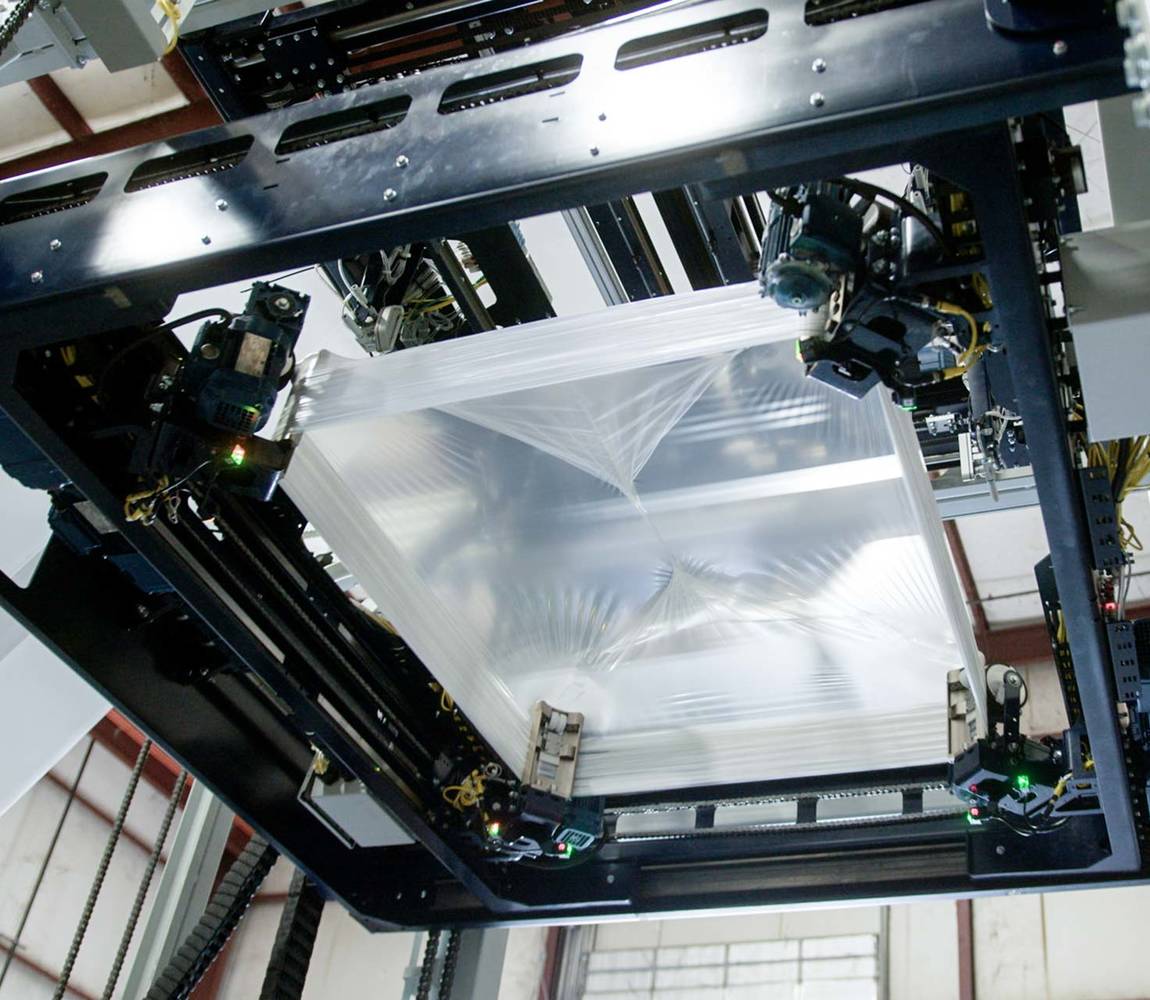

CHRONOS LSH-1100Stretch hooder

Available in

Canada & USAThe CHRONOS Stretch Hooder efficiently secures pallet loads, wrapping them from top to bottom in one stroke, optimizing uptime efficiency.

The tight-fitting hood ensures load stability even when opened. It provides optimal outdoor protection against water, humidity, UV, and diverse weather conditions. The plastic film can be transparent or pre-printed with your logo, enhancing brand visibility at your customers’ sites.

Capable of securing various loads, including mixed, uneven, short, tall, heavy, and light, the pallet hooder requires minimal maintenance and is easy to operate.

Speed: up to 100 loads per hour*

Applications: bags, boxes, bottles, big bags, mixed loads, trays, and more

* Depending on load height, film thickness, and other specifications

Features

Optimal protection

- Ensures weather-resistant loads

- Wraps tightly around various products and load sizes with up to 150% film elasticity

- Prevents film tails and loose film underneath the pallet

Ease of use

- Automatically detects load heights and centers pallets on the conveyor

- Can accommodate multiple lines and various load sizes with stored recipes

- Mobile film-loading system lowers the film carriage to a safe working height

- Equipped with safety fences and interlocking doors

Cost-effective

- Hoods up to 2000 loads per roll, offering extended autonomy compared to other technologies*

- Ensures consistent and minimal film consumption, providing stable operating costs

- Eliminates the need for top sheets

- Uses low air and power consumption

* More or less, depending on load and film characteristics

Specifications

Typical footprint 305" L x 212" W x 182" H (7747 mm x 5385 mm x 4623 mm)

Stretch dimensionsUp to 56" L x 46" W short side leading

(Long side leading option available)

Pallet load Height: up to 10' (3050 mm)

Weight: up to 4400 lbs (heavy-duty option available)

Electrical requirements 480 V / 60 Hz

Operating temperature 40°F to 104°F (5°C to 40°C)

"The difference that the stretch hooder makes compared to our old wrapper is that it's probably three times as fast and it's very efficient. It keeps our product on the pallets better and it's not as loose, so that's one thing we're very happy about."

Dallas Stevenson

Maintenance for Packaging Operations, Grain Millers