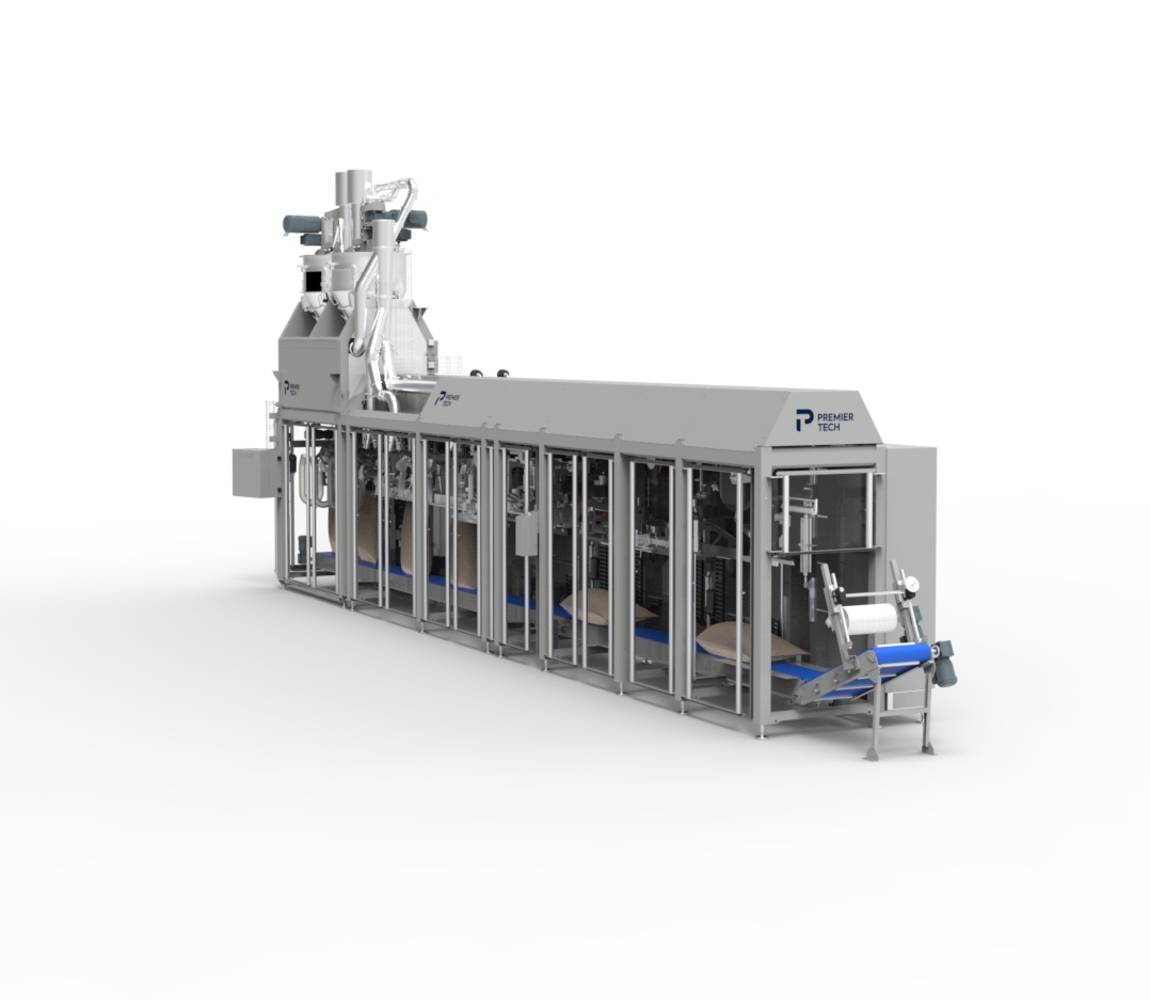

CHRONOS BFH SERIESHygienic open-mouth bottom-up filling system

Available in

Asia, Europe, Latin America and OceaniaThe BFH Series open-mouth bagging system features patented technologies designed for the precise and hygienic bagging of powdery bulk materials such as milk powder, baby food, chemicals, and pharmaceuticals.

Once the bag is placed, the filling spout moves the bag down the vertical filling screw during the filling cycle. The machine maintains a minimal distance between the filling point of the vertical filling screw and the product to significantly minimize dust emission and reduce product aeration.

Easy to clean and maintain, this machine offers fast changeover times and minimal dust emission, meaning more money in your pocket.

The patented bottom-up bagging system can be configured with single, single with post dosing, or double spouts.

Speed: up to 7 bags per minute (420 per hour)

Bulk materials: powders and granules

Bag types: pillow, gusseted, and block and cross bottom

Bag materials: woven PP, PE, and paper with inner liner

Bag weight: 22 to 66 lb (10 to 30 kg)

Features

Safe and sanitary

- The frequency / servo-control driven vertical screw fills powdery products hygienically, accurately and quickly

- Minimal dust emission and hygienically welded product contact parts

- Excellent accessibility for cleaning and maintenance

- No machine fasteners in critical product contact zones

- Bag top can remain closed during bag transportation

- ATEX-compliant design

Simple, safe, and durable design

- Control area separated from the functional bagging zone

- Cables to integral control centres run at the rear of each machine module

- Customisable system configurations

- Compact sturdy design suited for tiny spaces

- User-friendly touch control panel with integrated graphical user interface

High performing

- High weighing accuracy (up to 10 grams)

- Product de-aeration

- Field-proven technology for high system availability

- Large bag magazine for long production runs

Options

- Gas flushing

- Product sampler

- Automatic and semi-automatic versions

- Inert gas packing

- Servo-controlled dosing

- Stainless steel construction

- Standard bag marking systems

- Compatible with multiple bag closing systems (fully integrated)

- Extra positions for empty bag piles

- Bag turning

- Closed bag push-off

- Empty bag labeling

Get pricing and additional information

Need help finding the right open-mouth bagger?

Request a quote

Tell us about your project, and we will reply with solution recommendations