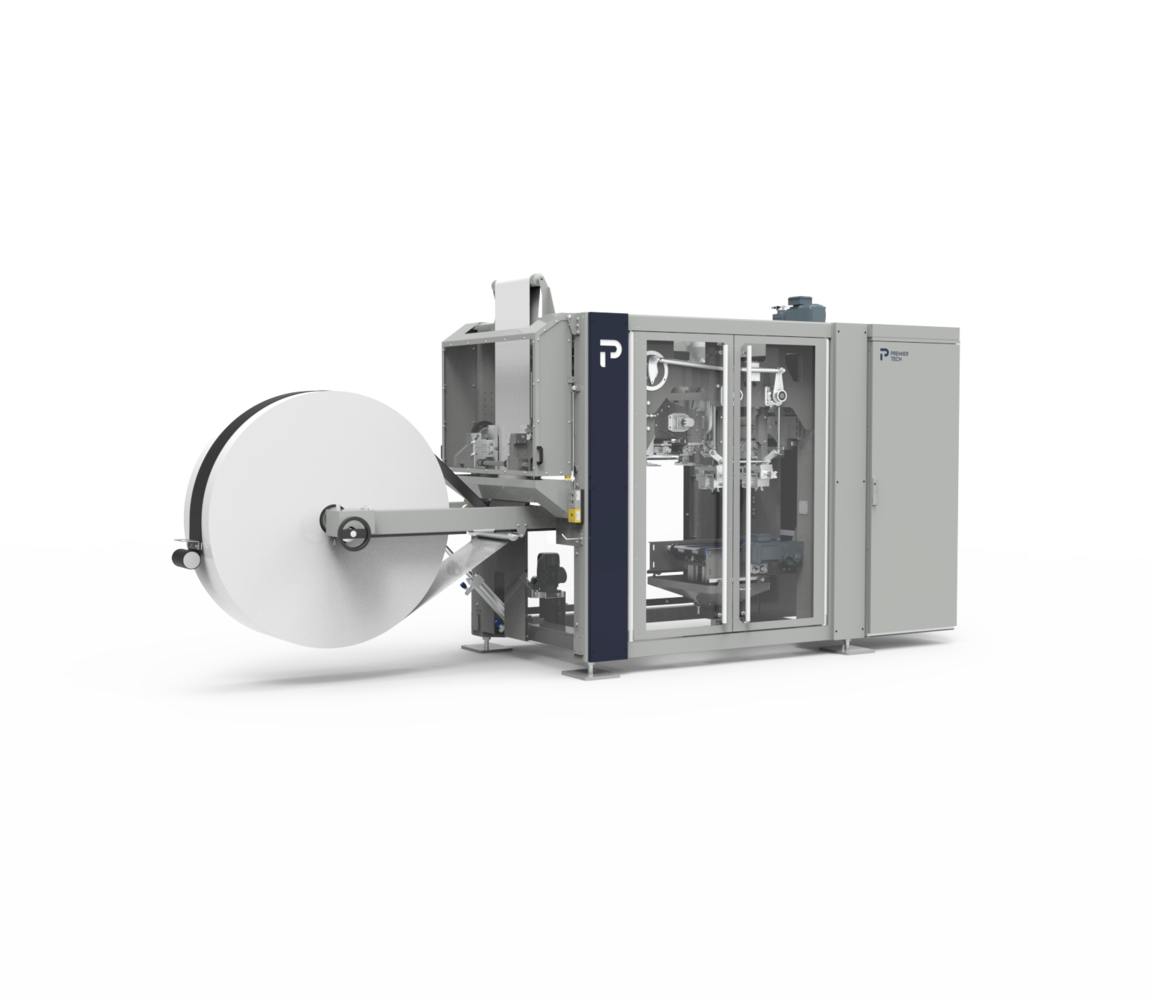

CHRONOS FST SERIESTubular form fill and seal bagging machine

Available in

Africa, Asia, Canada & USA, Europe, Latin America and OceaniaThe FST Series Tubular Form, Fill, Seal Bagger provides a versatile, flexible, and economical packaging system for tubular film. It efficiently handles various free-flowing products from the industrial, chemical, and nutrition industries, including plastic pellets, resins, special polymers, fertilizers, and animal feed.

This bagging machine provides fast-paced performance by simultaneously forming, filling, and sealing bags. It can adjust quickly for different bag lengths and widths and is adaptable to virtually any production capacity.

The installation is quick and easy, and the design allows full access to control, adjustment, and maintenance, all within a small footprint.

Speed: up to 33 bags per minute (2000 bags per hour)*

Bulk materials: granules, pellets, powders

Bag types: tubular film

Bag materials: PE, PP, aluminum PP

Bag weight: 5Kg to 50 Kg

* Depending on application and machine configuration

Features

Performant

- Precise filling and fast-paced packaging

- Quickly adjustable to different bag sizes with over 100 recipes storable

- Film roll reduces operational interaction by handling up to 3000 bags before changeover

Easy to use

- Intuitive touch screen HMI with graphic 3D images for simple operation and easy troubleshooting

- Tool-free adjustment and part replacement

- New film roll can be installed in less than 2 minutes

Optimized construction

- Open design allows full and simple access to controls and components

- Easy to wash and clean between products

- Integrated control cabinet for easy installation and minimal floor space usage

- Low power and air construction

Specifications

Typical footprint 5100 x 1600 x 2400 mm (200" L x 63" W x 94" H)

Empty bag dimensions Width: 350 mm to 450 mm (12" to 18")

Gusset: 35 mm to 100 mm (1.5" to 4")

Film thickness: 100 microns to 250 microns

Film roll Diameter: 1500mm (60")

Internal core: 150 mm (6")

Electrical requirements 400V/50 Hz/3PH + N

460V/60 Hz/3PH + N

Ambient temperature 5 ⁰C to + 40 ⁰C (40 F to 104 F)

Get pricing and additional information

Need help finding the right form fill and seal bagger?

Call us

We will be happy to answer

your questions

Sales

Parts & technical support

Request a quote

Tell us about your project, and we will reply with solution recommendations