Household products packaging machines

Whether you are packaging toilet paper, soap, shampoo, paper towel, diapers, detergent or other household products, Premier Tech can help automate the packaging operations that follow the primary packaging phase of your product.

Our RPK Series Robotic Case Packer is a versatile solution that can pack virtually any kind of product into cases and trays at up to 90 products per minute. On a complete line, this can be followed by either a conventional or robotic palletizer for speed and flexibility. We also offer a range of pallet wrapping machines, which can wrap up to 100 pallets per hour.

Equipment we recommend

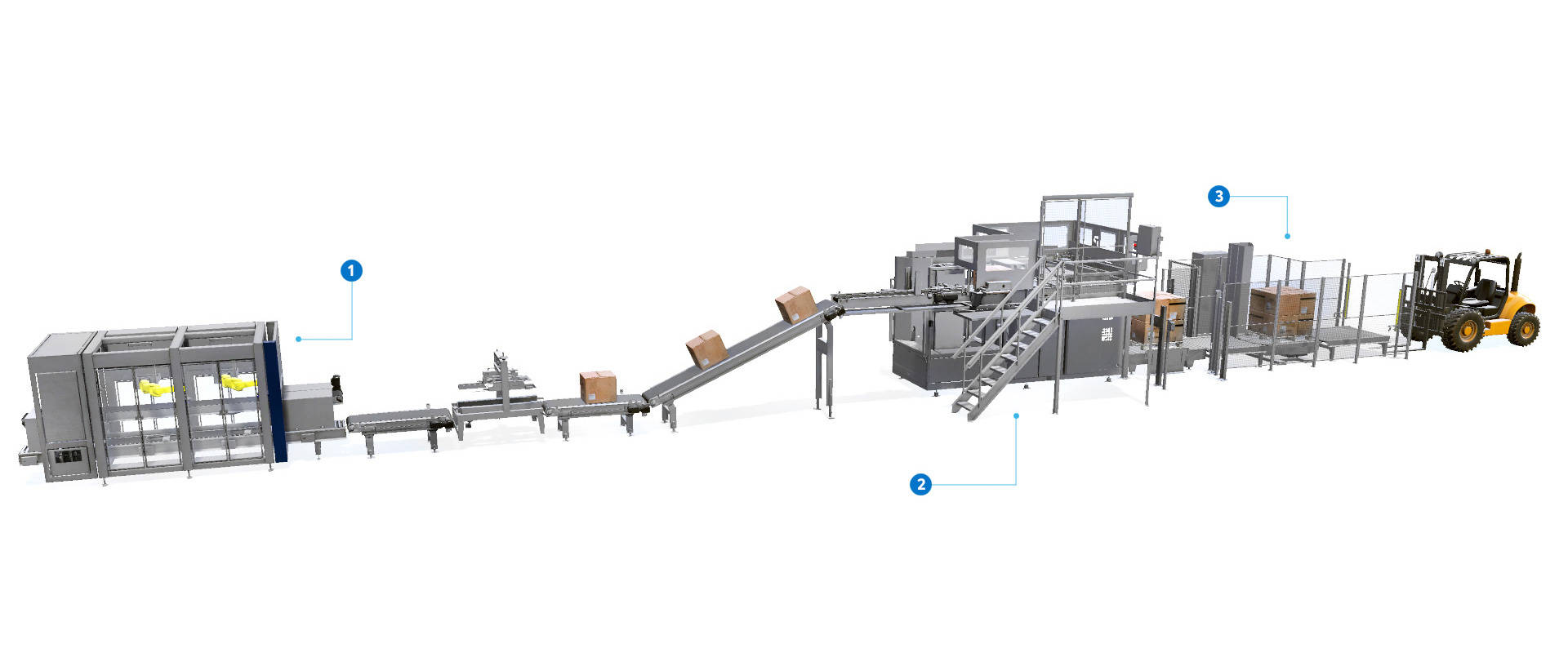

Packaging line for household products

Legend

- Robotic case packer

- Conventional palletizer

- Stretch wrapper

Ready to get started?

When it comes to industrial equipment, every detail matters. That’s why our team is dedicated to providing you with the support you need. Whether you are interested in a specific product, need technical support, or just want to give us your feedback, we’re here for you.