Beverages packaging machine

The beverage industry involves a variety of container types including glass, plastic, and carton. Container breakage and damage can become an issue when the product is not handled properly.

Premier Tech’s case packers rise to the challenge of handling beverages with both speed and care. Through the acquisition of vonGAL in 2012, we gained a special footing in the beverages industry, and our solutions are engineered to handle a wide range of containers, like bottles, jugs, bundles, and more.

Additionally, our equipment is designed to efficiently mix and match different products, allowing for the creation of multi-flavour packs on a single machine. For palletizing, Premier Tech offers conventional or robotic options.

All of our equipment complies with stringent safety standards and can be customized to fit the specific space requirements of your facility.

Equipment we recommend

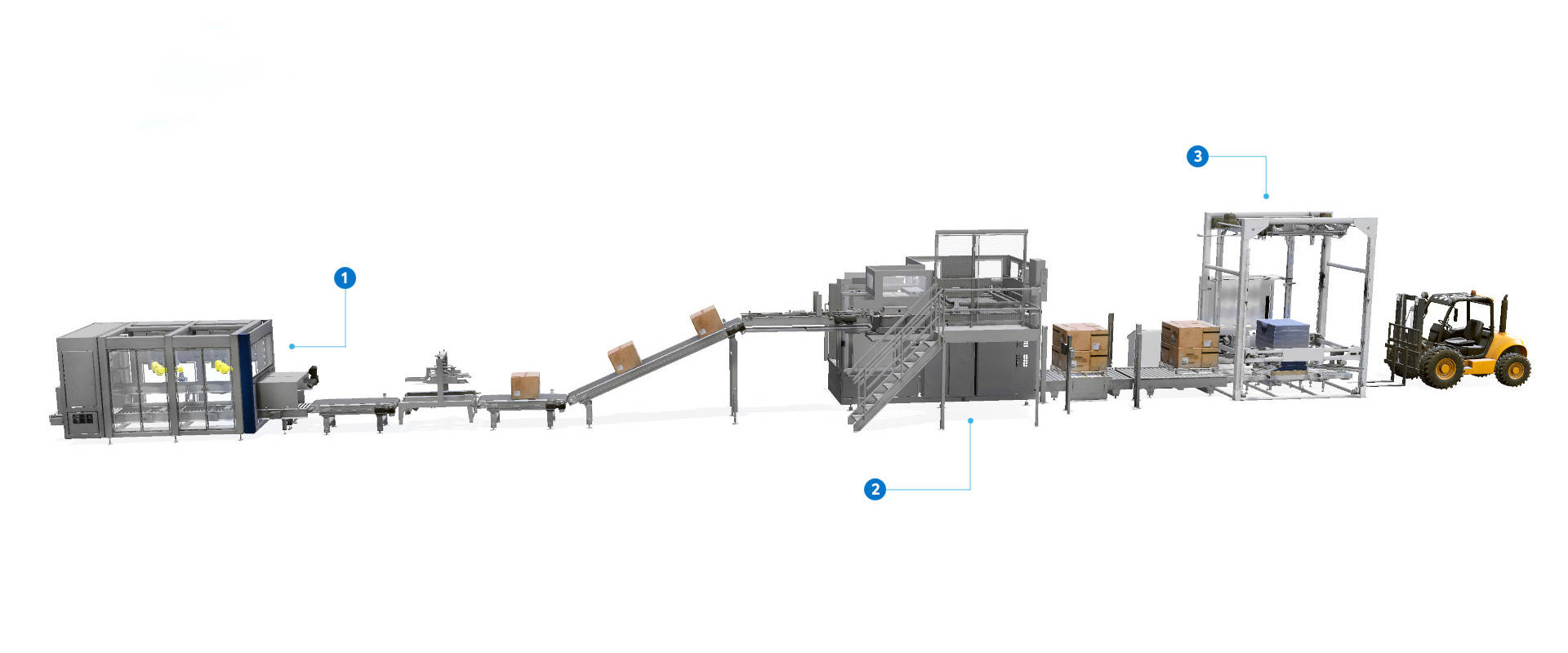

Packaging line for beverages

Legend

- Robotic case packer

- Conventional palletizer

- Stretch hooder

Ready to get started?

When it comes to industrial equipment, every detail matters. That’s why our team is dedicated to providing you with the support you need. Whether you are interested in a specific product, need technical support, or just want to give us your feedback, we’re here for you.

Testimonial

“One of the selling point of this equipment is we saw how simple it was to switch from one bottle size to another.”

Brian Mattingly

Operations Director, Maker's Mark