Automatic open-mouth bagging machines

Improve the safety and capacity of your packaging line with an open-mouth bagging system. Our offerings meet the highest standards for accuracy, reliability, and performance.

Our portfolio includes moderate to high-speed models, and sanitary and compact open-mouth bagging solutions with varying levels of automation.

With over a century of experience following the acquisition of Chronos Richardson in 2001, we are a leading manufacturer of open-mouth baggers for bags 5kg and heavier.

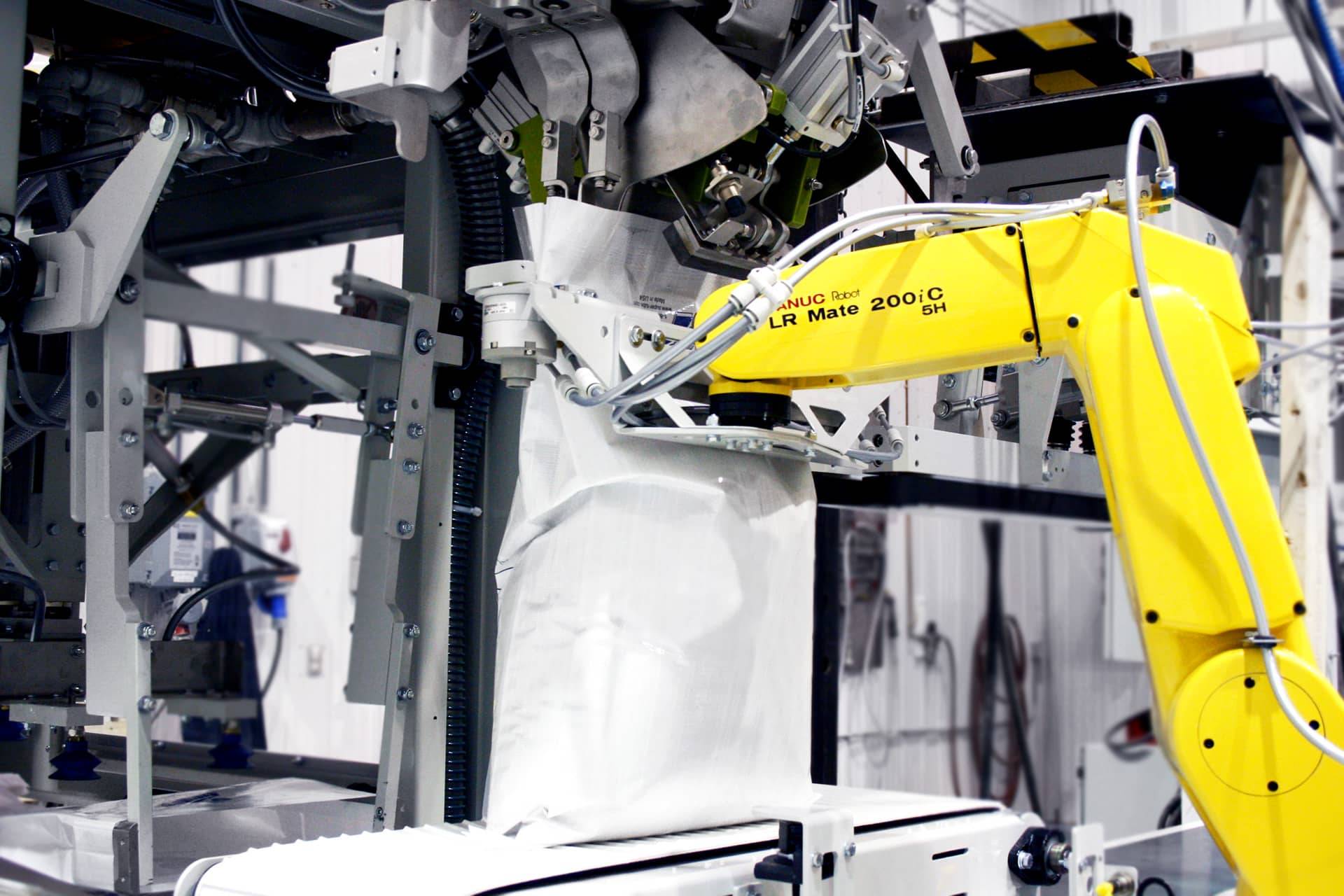

Automated open-mouth baggers are designed to fill and seal pre-made open-mouth bags quickly and efficiently.

Product is weighed via a net or gross weight scale and fed into a bag. The bag moves through a sealing station, after which it can go be further processed or palletized.

Our automated open-mouth bagging machines

Our open-mouth baggers are manufactured with varying levels of automation, and offerings vary by region.

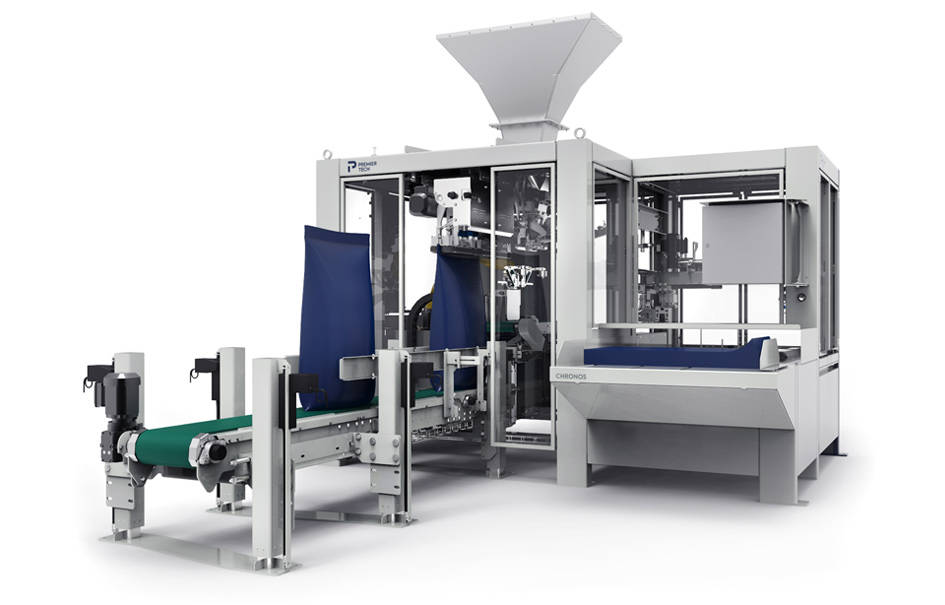

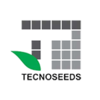

Fully automatic open-mouth bagging machines

- This series handles all kinds of granules and powders and features three models suited to different production capacities, budgets, and floor space.

- Handles paper, polyethylene, laminated and non-laminated polywoven bags.

- Built locally in Asia, Europe, and Latin America.

What open-mouth baggers can do and handle

Our bagging machines can pack a variety of dry products into 25, 50, and 100 lb pre-made bags.

Various bulk materials

- Granules and pellets like pet food, animal feed, rice, cereal grains, and fertilizers

- Powders like flour, sugar, starches, and milk powder

Many bag types

- Materials: paper, polyethylene, and polywoven

- Formats: gusseted, pillow, and block-bottom

Diverse speeds

- High: up to 27 bags per minute (1620 per hour)

- Moderate: up to 20 bags per minute (1200 per hour)

- Low: up to 7 bags per minute (420 per hour)

Features that have earned the trust of industries around the globe

Our open-mouth bagging systems have been finetuned over many years and provide proven and dependable service.

Extremely accurate bagging scales

Combined with a selection of top-of-the-line gross or net bagging scales, our equipment fills bags quickly and accurately, reducing product loss and increasing your profit with each bag.

Varying levels of automation

Whether you opt for an entry-level model with some automated features, or a higher end, high-speed open-mouth bagger that provides full automation, we're here to help you make the right choice.

Sanitary design and clean operations

Food safety, hygiene, and cleanliness are important for many customers. That's why our bagging systems feature dust-free operations, stainless steel contact points and are designed to prevent contamination.

Highly reliable and sturdy design

Robust industrial construction ensures minimal downtime while delivering exceptional efficiency.

Ergonomic design of key components simplifies operation and offers easy access for cleaning and maintenance.

Intuitive and easy to operate

Our bagging machines are controlled via PLC with a user-friendly HMI.

Operators can select recipes, adjust bag sizes, and start new batches in a matter of seconds through the simple touchscreen interface.

Held to the highest safety standards

Equipped with the latest safety features, our packaging lines can be adapted to the specific regulations of different countries and market segments, such as:

- Safety doors with trapped key interlocking

- Light curtains

- Emergency-stop buttons

- Guarding

- Dust removal system

- Separated electrical and control panels

Additional features

We care about making your packaging line as functional as possible and offer a selection of integrations to meet your specific needs:

- Dust control spout and collection system

- Bag deaeration

- Compatible with any bag closing and sealing machines

- Various bag identification options

- Flattening press

- Metal detectors

- Built-in connectivity for 4.0

Get a quote

Tell us more about your project and we will send you recommendations and a free quote.

Lifecycle management

Personalized customer service to maximize your equipment performance and lifespan

Lifecycle management

Personalized customer service to maximize your equipment performance and lifespan

Technical support

Qualified technical support available 24/7 for remote troubleshooting

Technical support

Qualified technical support available 24/7 for remote troubleshooting

Operator training

Practical operator training that ensures a smooth transition to automation

Operator training

Practical operator training that ensures a smooth transition to automation

“We were looking for a solution to meet our wish list. Premier Tech met not only our wish list, but instead of an ROI of 3 years, it was just over 2 years.”

Michelle Clark

Vice President of Finance and Accounting, Lifeline Foods

Need help choosing the right open-mouth bagging equipment?

Request a quote

Tell us about your project, and we will reply with solution recommendations